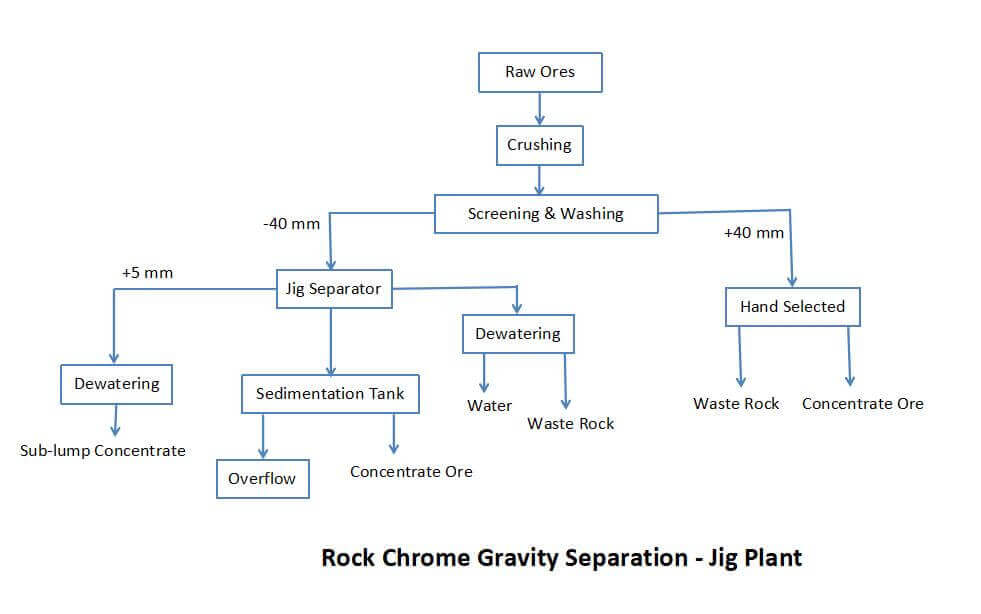

Gravity separation is a common method used to beneficiate chrome(chromite) ore, especially for the concentration of heavy minerals like chrome. In the gravity separation process for rock chrome, the principle is to separate the valuable minerals from the gangue based on the difference in density or specific gravity.

Rock Chrome Gravity Separation

Release time:29 March 2024Rock Chrome Gravity Separation Process

Crushing and Grinding: The ore is crushed and ground to liberate the chromite particles from the gangue minerals. It ensures the full release of chromite grains for effective separation.

Gravity Separation: After crushing and grinding the ore, use gravity separation technology. The gravity concentration exploits the differences in specific gravity between chromite and the gangue minerals. Various equipment can be used for gravity concentration, including shaking tables, spirals, centrifugal concentrators, and jigging machines.

Shaking Tables: Shaking tables are equipped with riffles that trap heavy minerals while allowing lighter gangue particles to be washed away. Chromite particles settle into the riffles and are concentrated.

Spirals: Spirals utilize centrifugal force to separate minerals based on their specific gravity. Chromite particles are carried upwards along the spiral while lighter gangue minerals are washed away.

Centrifugal Concentrators: These devices use centrifugal force to concentrate minerals. Chromite particles are focused on the center of the centrifuge, while lighter gangue materials are expelled.

Jig Concentrators: Jigging machines utilize pulsating water flow and a bed of particles to separate minerals based on their specific gravity. Chromite particles settle into the jig bed, while the flowing water carries away lighter gangue minerals.

Dewatering and Tailings Disposal: After gravity concentration, the chromite concentrate is dewatered to reduce moisture content. The gangue material separated during gravity concentration is usually discarded as tailings.

Rock Chrome Process Plant

This setup is a 500 TPD rock chrome processing plant. It is configured with a jaw crusher, cone crusher, ball mill, trommel screen, spiral chute separator, shaking table, etc.

Rock Chrome Gravity Separation Process Plant – Shaking Table

Rock Chrome Process Details:

- An excavator or wheel loader feeds the raw ore into the raw ore hopper. Under the hopper is a vibrating feeder with a grizzly bar, which can be made with a 100mm grizzly gap. Larger than 100mm will go to the jaw crusher for the first crushing. Less than 100mm will go down the belt conveyor under the jaw crusher, and the output from the jaw crusher will be transported with this same belt.

- The jaw crusher crushes a big stone(like 425mm) into a smaller one, around 100mm.

- The crushed stone is transported to the next cone crusher for a second crushing by a belt conveyor. The cone crusher’s output stone is around 15 or 20mm smaller.

- The crushed ore is transported to the next vibrating screen for screening. Stones larger than 15 or 20mm are sent to crush again. Less than 15 or 20mm goes to the following storage hopper by belt conveyor.

- Under the hopper, there is a small electromagnetic vibrating feeder that feeds the material evenly to a belt conveyor.

- The ball mill grins the small gravel into less than 0.5mm powder.

- The ground powder from the ball mill goes to the trommel screen for 100% screening, controlling the output to less than 0.5mm. We formed a closed loop here. The part larger than 0.5mm returns to the storage hopper and the ball mill.

- The less than 0.5mm slurry from the trommel screen goes to the first-stage spiral chute separator for the first separation. Then, the middlings from the first-stage spiral chute go to the second-stage spiral chute for separation again.

- All the concentrates from these two-stage spiral chute separators will be sent to the shaking table for final separation.

JXSC Mine Machinery Factory is an experienced mining equipment and mineral solutions supplier. If you need mineral beneficiation, don’t hesitate to contact us.

Related Product

Contact Us Now

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours. Rest assured that we won’t reveal your information to anyone.