According to the different physical and chemical properties of rare earth minerals, associated gangue, and other minerals, the beneficiation of rare earth ore usually adopts the following methods.

1. Radiation Beneficiation Method

It mainly uses the difference in thorium content between rare earth minerals and gangue minerals in the ore, and uses a γ-ray radiation concentrator to separate rare earth minerals from gangue minerals. The radiation beneficiation method is mostly used for the pre-selection of rare earth ore. At present, this method is not widely adopted in the industry.

2. Gravity Beneficiation Method

The density difference between rare earth minerals and gangue minerals is used for sorting. Commonly used gravity separation equipment includes cone concentrator, spiral concentrator, shaker, etc. Gravity separation is mainly used to separate rare earth minerals from low-density quartz, calcite, and other gangue minerals to achieve the purpose of pre-enrichment or to obtain rare earth concentrates. Gravity separation is widely used in the production of seashore placers; it is sometimes used as a means of pre-enrichment in the beneficiation of rare earth veins.

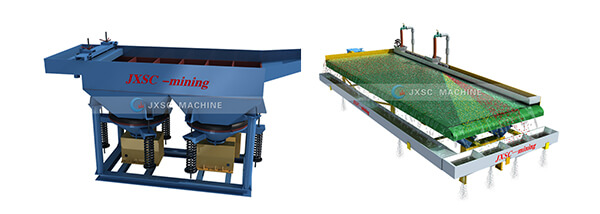

Gravity Beneficiation Equipment

Shaker: It is also known as gold shaking table, gold separation table, it is a fine gold recovery equipment common in the gold shaker wash plant, alluvial gold mining plant to separate concentrates, medium concentrates, and tailings according to material density and grain size.

Spiral Chute: It is the best equipment for mining and mineral processing, which combines the characteristics of the spiral concentrator, shaking table, and Centrifugal concentrator. It is made of fiberglass lined with wear-resistant polyurethane and corundum cover, light moisture-proof, anti-rust.

Jig Concentrator: It is an effective gravity separation machine based on the ore material density difference. The jigging machine is mainly used for processing placer gold, coltan, tungsten, tin, etc. higher the density difference, the better the jigging separation effect.

Gold Centrifugal Concentrator: It is a brilliant gravity separation equipment widely used in the mining industry, especially for placer gold, fine grain rock gold, and other precious minerals.

3. Magnetic Separation Method

Some rare earth minerals are weakly magnetic. The difference in specific magnetic susceptibility between them and associated gangue and other minerals can be used to separate rare earth minerals from other minerals by using magnetic separators with different magnetic field strengths. In the beneficiation of seaside placers, weak magnetic separation is often used to separate ilmenite from monazite; strong magnetic separation can also be used to separate monazite from zircon, quartz, and other minerals. In the beneficiation of rare earth veins, in order to simplify the flotation process and save flotation reagents, sometimes strong magnetic separation is used to pre-enrich rare earth minerals. With the continuous development of strong magnetic technology, strong magnetic separation will be more and more widely used in the beneficiation process of rare earth ore.

Magnetic Separation Equipment

The wet drum magnetic separator is a commonly used iron ore processing equipment (iron ore magnetic separator) and manganese ore equipment (manganese ore magnetic separator) and is a mainstream strong magnetic separator ore dressing equipment.

Three-Disc Dry Magnetic Separator applicable to dry separation of titanium, rare earth ore, tungsten-tin ore, chromite, niobium-tantalum ore, Limonite, Zircon, gold red, solitary, feldspar, quartz, and other magnetic differences in a variety of metallic minerals or non-metallic materials of the iron remover, but also magnetic and non-magnetic minerals separation purification.

Dry Drum Magnetic separator is one of the most widely used and versatile machines in mineral processing. Mineral technologies electrostatic separators suitable for manganese ore, magnetite, pyrrhotite, roasting ore, ilmenite, hematite, and other materials below 50mm granularity, dry magnetic separator, and wet drum magnetic separator.

High-intensity magnetic separators are the upgrading products of dry separators developed on the basis of the original dry separators by improving the magnetic field strength and magnetic block arrangement. Its magnetic system is all made of high-performance rare-earth nd-fe-b material and high-quality ferrite material with high magnetic field strength (up to 12000 GAUSS). The high-intensity magnetic separator is suitable for wet magnetic separation of magnetite, pyrrhotite, roasted ore, ilmenite with particle size less than 3mm, and also for removing iron from coal, non-metallic ore, building material, etc.

4. Flotation Method

Taking advantage of the difference in surface physical and chemical properties of rare earth minerals and associated minerals, flotation is used to separate them from associated gangue and other minerals to obtain concentrates, which is currently the main beneficiation method widely used in the production of rare earth veins. The Rare Earth Mine of Mountain Pass in the United States uses flotation to produce rare earth concentrates. In the production of seashore placers, after the heavy sand is obtained by gravity separation, the flotation method is often used to obtain rare earth concentrates from the heavy sand.

Flotation Equipment

Flotation machine (planktonic concentrator) in the mineral processing plant, mainly used for separating copper, zinc, lead, nickel, gold, and other non-ferrous metal.

Mixing Tank for flotation pulp operation prior to mixing, so that the pulp with a pharmaceutical fully mixed as to create conditions for the flotation processing, and also suitable for blending various kinds of nonmetal ores.

5. Electric Selection

Rare earth minerals are poor conductors, and their electrical conductivity can be used to be different from associated minerals, and they can be separated from minerals with good electrical conductivity by electric separation. Electric separation is often used in the selection of seashore placer heavy sand.

Electric Separation Equipment

The Electrostatic Mineral Separation is used for recycling various minerals, waste metals, and non-metal materials with conductivity differences such as selected white tungsten, tinstone, zirconite, andalusite, rutile, and gold placer.

The ARC type Electrostatic Separator is mainly used for separating a small number of metallic conductor minerals from nonmetallic materials, especially for separating and purifying placer ores.

6. Chemical Beneficiation Method

For rare earth deposits adsorbed on kaolin or clay in the form of ions. It can make full use of the feature that rare-earth ions are easily soluble in sodium chloride or ammonium sulfate solution, and adopt a chemical beneficiation method of leaching first and then precipitation for recovery. For fluorocarbonate rare earth minerals that are easily soluble in acid or undergo phase change at high temperatures, they can be pre-enriched by flotation, and then purified by chemical beneficiation methods (acid leaching or high-temperature roasting).

LATEST PRODUCTS

Double Vibration Motor Feeder

【Capacity】30-300 t/h 【Feeding Size】0-550 mm …

Belt Feeder

【Capacity】 10-450 t/h 【Power】 1.5-2.5 kW/Mete…

Twin Screw Feeder

【Feeding Capacity】 10-160 t/h【Power】 2.2-…