Whether the magnetic separation equipment is reasonable, advanced, and efficient determines the pros and cons of the beneficiation process. Paying attention to the research of magnetic separation equipment can make the mine beneficiation process more optimized. Centralized crushing and centralized sorting may become the trend of the future mining industry. With the increasing scarcity of mineral resources and the continuous improvement of production requirements, the sorting requirements of energy and mining materials will continue to increase.

The embedded particle size of magnetite is not uniform. In order to separate the monomer of magnetite to meet the technological requirements, the minimum embedded particle size must be used as the standard for grinding. In the design of magnetic separation equipment, mechanical factors such as wind force, centrifugal force, gravity, electric field force, water capacity, etc., which are conducive to the separation of materials, should be introduced to achieve the purpose of efficient separation.

Although magnetic separation equipment is a clean separation method, magnetic separation equipment inevitably consumes a lot of electricity and water. With the increasing emphasis on energy conservation and consumption reduction in the mining market, upgrading magnetic separation equipment is also an essential part of energy conservation and consumption reduction. Magnetic separation is a material separation processing technology that has been widely used in many industrial fields. In mineral processing, magnetic separation technology has made significant progress. The magnetic separation equipment has also developed by leaps and bounds due to the development of permanent magnet materials, the improvement of the performance of permanent magnet materials, and the gradual increase of the magnetic energy product of permanent magnets. The magnetic separator’s structure varies, and there are many classification methods.

- According to the strength of the magnetic field, it is divided into the weak magnetic separator, medium magnetic separator, and strong magnetic separator;

- According to the separation medium, it is divided into the dry magnetic separator and the wet magnetic separator;

- According to the magnetic source, it is divided into permanent magnet magnetic separator and electromagnetic magnetic separator.

What types of magnetic separators are there?

1. Dry Strong Magnetic Separator

Dry strong magnetic separators have been used in industry for more than 50 years, mainly for the separation of coarse-grained minerals. With the development of rare earth permanent magnet materials, a permanent magnet roller magnetic separator with a higher magnetic force than a strong magnetic field electromagnetic separator has been manufactured. Although the magnetic induction intensity is not easy to adjust, it is possible to design a roller magnetic separator that can handle materials with different particle sizes and different specific magnetic susceptibility by selecting the permanent magnet material reasonably and optimizing the geometry of the roller. The weight and size of the permanent magnet roller magnetic separator are smaller than that of the electromagnetic induction roller magnetic separator, and there is no air gap, which can handle large particles, making the permanent magnet roller magnetic separator a great technical and economical effect. First, magnets of different grades and sizes can be used to reduce costs; second, electromagnet modeling software can be used to optimize magnet design. For the dry pre-selection of weak magnetic iron ore, in recent years, the dry-type strong magnetic separator has been used to replace the gravity separation equipment, so the pre-selection index has been significantly improved.

2. Dry weak magnetic separator

The main purpose of the dry weak magnetic separator is to remove iron filings and ferromagnetic impurities or to enrich the ferromagnetic useful components. Suspended magnets, magnetic pulleys, plate magnets, or grid bar magnets are generally used to remove iron filings and ferromagnetic impurities, while magnetic drums are mainly used to enrich ferromagnetic useful components. At present, dry weak magnetic separators are commonly used in mines in my country to preselect strong magnetic minerals. Before coarse crushing, medium crushing, fine crushing, and grinding, the use of lump ore dry weak magnetic separation can throw more than 80% of the waste rock mixed into the ore, which increases the grinding processing capacity, improves the grade of the ore for grinding, and reduces the energy consumption.

3. Wet weak magnetic separator

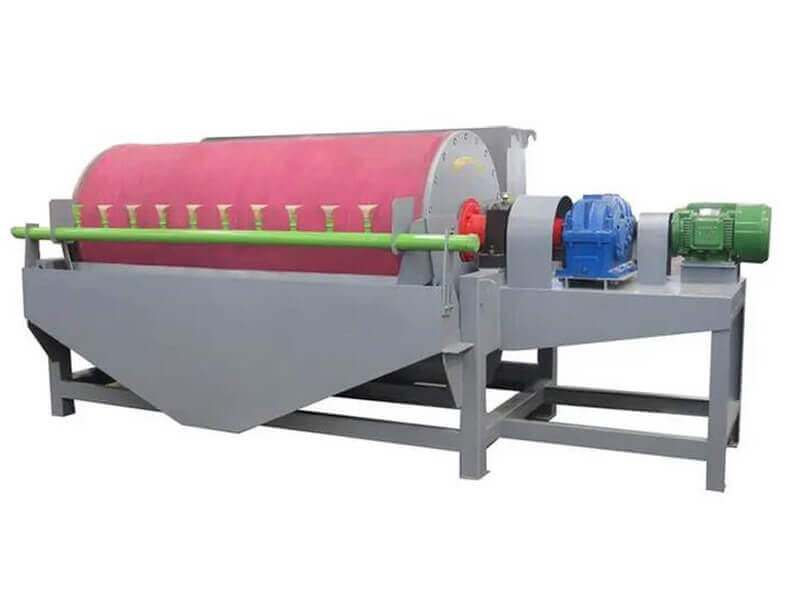

The magnetic drum separator is the most commonly used wet-weak magnetic separator. With the emergence of NdFeB permanent magnet materials, the permanent magnet magnetic separator has almost completely replaced the electromagnetic drum magnetic separator. This magnetic separator is mainly used to recover the medium in heavy medium beneficiation, such as magnetite and ferrosilicon. The enrichment of strong magnetic minerals is another application of this magnetic separator. The use of rare earth permanent magnets and further improved their properties have expanded the wet-type magnetic separator to separate medium-magnetic and weakly-magnetic materials.

The magnets of the permanent magnet drum separator are available in two designs: radial configuration and axial configuration.

- In the radial configuration, the polarity of the permanent magnets alternates across the width of the barrel;

- In the axial configuration, the permanent magnets’ polarity alternates along the barrel’s circumference.

Radial configuration is generally used to improve the recovery rate of ferromagnetic materials. The change in the polarity of the axially arranged magnets causes the sorted particles to tumble on the surface of the magnets, thereby releasing the entrained non-magnetic particles from the magnetic product, which can improve the grade of the magnetic concentrate.

A wet drum magnetic separator is the primary sorting equipment for strong magnetic iron ore. At present, great progress has been made in the ore feeding method, magnetic system design, tank type, transmission mechanism, large-scale, specialization, and high efficiency.

The selection equipment for strong magnetic iron ore includes low field strength multi-pole magnetic separator, magnetic aggregation machine, magnetic separation column, vertical pulse vibration magnetic separator, low field strength pulsation magnetic separator, low field strength self-weight jumper Elimination machines, etc. Its typical feature is to use the combined action of a weak magnetic field and gravitational field to remove the magnetically mixed gangue and improve the iron grade of the concentrate. More, the selection effect is good.

4. Wet magnetic separator and high gradient magnetic separator

Introducing the medium into the magnetic circuit of the magnetic separator can make the magnetic separation method process the materials that were considered too fine and too weak to select other materials in the past. Jones studied this in 1960 and combined the Frantz concept of magnetized media with strong magnetic fields. A more advanced magnetic separator design according to the Jones concept is the SALA high gradient magnetic separator. Although a variety of multi-cycle and continuous wet high-gradient magnetic separators have been designed and manufactured, only a few magnetic separators can meet the mining industry’s requirements. The purification of kaolin and the beneficiation of iron ore and placer are examples of successful applications of this magnetic separator.

Fine-grained weak magnetic iron ore must be separated by strong magnetic separation equipment. Two SHP and SLON types are currently widely used in domestic iron ore processing plants. The typical representative of this type of equipment is the vertical ring pulsating high gradient magnetic separator, which is a high-efficiency magnetic separation equipment suitable for sorting fine-grained weak magnetic minerals.

The advantages of vertical ring pulsating high gradient magnetic separator:

- Large enrichment ratio

- High sorting efficiency

- Magnetic medium is not easy to be blocked

- Strong adaptability to the fluctuation of feeding particle size, concentration, and grade

- Reliable work

- Easy to operate and maintain

Application of superconducting technology in magnetic separation

Although the application of superconducting technology to magnetic separation process equipment is of great significance, its importance in magnetic separation does not seem to be manifested. Since the need for magnetic induction above 2T is not yet apparent, the main advantages of superconducting magnets are reduced energy consumption and weight of the magnetic separator. Superconducting magnets can also be applied in an open gradient helical configuration without using a medium to generate strong magnetic forces in large volumes. Removing quasi-colloidal weak magnetic iron and titanium oxides to purify kaolin is the primary purpose of a high superconducting gradient magnetic separator.

In recent years, the large-scale application of rare earth permanent magnets has greatly accelerated the permanent magnetization process of magnetic separation equipment. Due to the application of high technology and the development of automatic control, the sorting accuracy of magnetic separation equipment is getting higher and higher. Mainly in improving sorting accuracy, expanding application fields, increasing processing capacity, adopting new magnetic materials, saving energy, reducing consumption, etc. Large-scale, specialized, and energy-saving equipment is the focus of the future development trend and magnetic separation equipment market competition.

LATEST PRODUCTS

Twin Screw Feeder

【Feeding Capacity】 10-160 t/h【Power】 2.2-…

Tubular Screw Conveyor

【Capacity】6-50 m3/h【Procesible Material】 …

Heavy Plate Feeder

Capacity: 100-240 m3/h Power: 15-45 kW Speed: 0…