This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Home > Aggregates Processing Plant > Diabase Aggregate Processing

Diabase Aggregate Crushing

Material: Diabase

Application: Mining, metallurgy, construction, highway, railroad, water conservancy, etc.

Equipment: Jaw crusher, cone crusher, vertical shaft impact crusher, vibrating feeder, vibrating screen, etc.

Diabase Introduction

Diabase, also known as dolerite, is a type of intrusive igneous rock that is medium to dark gray or black. According to the different secondary minerals, it can be divided into olive diabase, quartz diabase, and so on. Diabase typically has a fine-grained texture and can sometimes display a porphyritic texture, with larger crystals (phenocrysts) embedded within a finer-grained matrix.

Diabase is a high-grade building material. It is known for its durability, strength, and resistance to weathering, which makes it suitable for various construction purposes. Diabase is often used as a crushed stone for road construction, railroad ballast, and as an aggregate in concrete. It is also used as a decorative stone in landscaping and for making monuments and sculptures.

Diabase’s Colors

Diabase typically appears medium to dark gray or black. The specific shade of gray or black can vary depending on the mineral composition and the presence of other minerals or impurities. The dark color of diabase is primarily attributed to dark-colored minerals such as pyroxene and, in some cases, olivine. The plagioclase feldspar minerals in diabase can also contribute to its color. Depending on their composition, plagioclase feldspars can range in color from white to gray.

Formation of Diabase

Diabase forms when molten magma intrudes into the Earth’s crust, cools, and solidifies underground. It is commonly found in dikes (vertical or near-vertical sheet-like bodies) or sills (horizontal or near-horizontal sheet-like bodies), and it can occur in a variety of geological settings.

Diabase Composition

Diabase is mainly composed of pyroxene and plagioclase feldspar (epigenetic rock with the same composition as gabbro) and contains a small amount of olivine, biotite, quartz, apatite, magnetite, ilmenite, etc.

- Plagioclase Feldspar: It is the most abundant mineral in diabase. It is a group of feldspar minerals with a continuous solid solution between sodium and calcium-rich varieties. The most common plagioclase feldspar found in diabase is labradorite or bytownite.

- Pyroxene Minerals: Diabase contains pyroxene minerals, which are dark-colored silicate minerals. The most common pyroxene minerals found in diabase are augite and hypersthene. These minerals contribute to the dark color and fine-grained texture of diabase.

- Olivine: In some diabase rocks, you may find olivine as well. Olivine is a greenish mineral less common in diabase than plagioclase feldspar and pyroxene minerals.

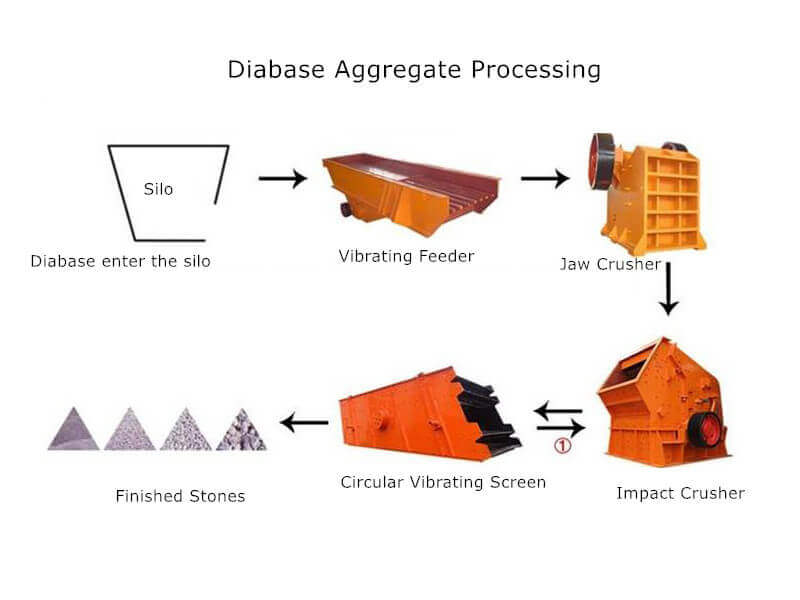

Diabase Aggregate Processing

- Large diabase stones are evenly sent to the jaw crusher by the vibrating feeder through the silo for coarse crushing.

- The belt conveyor sends the coarsely crushed stone to the impact crusher for further crushing.

- The belt conveyor sends the finely crushed stone to the vibrating screen for screening.

- Several stones of different specifications are screened out, and the stones that meet the particle size requirements are sent to the finished product stockpile by the belt conveyor.

- Stones that do not meet the particle size requirements are returned by the belt conveyor to the impact crusher for re-crushing, forming a closed circuit for multiple cycles.

The particle size of the finished product can be combined and classified according to users’ needs. It can equip with auxiliary dust removal equipment to protect the environment.

Diabase Crushing Production Line Features

The diabase aggregate crushing production line has a high degree of automation, low operating cost, high crushing rate, large output, less pollution, easy maintenance, uniform particle size, and reasonable matching. It has the characteristics of high investment and economic benefits, good quality crushed stone, and a low output rate of stone powder. At the same time, it is equipped with an advanced electronic control operating system to ensure smooth discharge of the entire process, reliable operation, convenient operation, and energy saving.

Diabase Sand Making Plant

Diabase processing divides into three stages: coarse crushing by jaw crusher, medium and fine crushing by cone crusher, and sand making and shaping by sand making machine.

The first stage: Coarse Crushing

Large diabase materials are evenly fed by the vibrating feeder through the silo and sent to the jaw crusher for coarse crushing. After the vibrating screen screens the coarsely crushed materials, use the belt conveyor to convey them to the cone crusher for finely crushing.

The Second Stage: Finely Crushed

After finely crushing the diabase with the cone crusher, a circular vibrating screen screens it and the material greater than or equal to 40mm is returned to the cone crusher for crushing again.

The Third Stage: Sand Making

Send the crushed diabase particles smaller than 40mm to the sand-making machine for further crushing and shaping, and the materials larger than or equal to 20mm back to the sand-making machine for fine crushing again, the material smaller than 20mm to the circular vibrating screen for screening and packaging. If clean diabase is needed, send it to the sand washing machine for cleaning.