XMQ Cone Ball Mill

【Capacity】:200 -4000g/h

【Feed size】:≤3mm

【Processible Material】:gold, lead-zinc, coltan, tantalite, iron ore, copper ore.

【Application】: It is mainly suitable for crushing processing of various metal and non-metallic ore raw materials test samples. At the same time, it is used for ultra-fine grinding processing of coatings, inks, fuel, and the food industry.

Chat Online on WhatsApp

Chat Online on WhatsApp

Advantages

XMQ cone ball mill is a laboratory grinding equipment for ore wet grinding. It is a key equipment that is crushed after the material is broken. It can wet and dry grinding(150 × 50 model cone ball mill can also be used for dry grinding). It is suitable for the feasibility study of ore in schools, scientific research institutes, and laboratories. It can also be available for metallurgy, geological chemicals, building materials, and coal, and research units and other fields. A high-quality ball mill crusher, the conical ball mill can grind many metal ores. Lab mill has the advantages of high grinding accuracy, large production capacity, simple operation and long service life.

JXSC is a professional mining laboratory grinding equipment manufacturer, get the first-hand ball mill price now. Besides, ball mill design is available—types of ball mills: conical ball mill, cylinder ball mill, rod mill.

【Features】

- Small-size, lightweight, multi-purpose new milling equipment can be dry and wet;

- Powerful motor, high milling efficiency, high processing;

- The tube electric control can set the abrasive time at arbitrarily, and the degree of operation is high;

- Adopting frequency conversion technology, the speed adjustment range is wide, and the abrasive, mix, and uniform look;

- Advanced product performance, reasonable structure, high efficiency of samples, and good sealing performance;

- The equipment installation does not require foundation, low noise, no dust pollution, easy to work;

- The granular size of the grinding material is uniform, the degree of crushing is small, and the quality of the ore finished product is guaranteed.

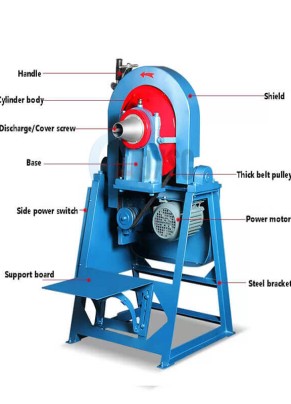

Product Structure

【Structure】

This machine consists of the main part of the feed department, the discharge department, the transfer department, the transmission department (the reducer, the small transmission gear, the motor, the electrical control). The empty shaft in this conical ball mill uses the steel casting part, which the lining can replace. The large gear is processed by casting the large gear. The tube is inlaid with wear -resistant lining plate and has good abrasion resistance. This machine is running smoothly and reliably work.

【Working Principle】

The special conical structure of the conical ball mill can naturally separate the grinding medium (steel ball), the big ball is located in the biggest diameter section of the cylinder body. The small ball is located in the conical section. The coarse material obtains the big impact of energy under the action of the big ball at the feeding end and completes the coarse crushing operation. The pellet is located at the cone end of the discharge to obtain more surface area for fine grinding. The characteristic of the cone mill is that it is equivalent to installing a permanent classifier in the mill barrel. The materials are arranged in the barrel according to the particle size, and the finer they are, the closer they are to the discharge outlet, which will not produce over-grinding, thus increasing the useful work and reducing the useless work In order to achieve the goal of energy-saving and consumption reduction.

Technical Parameters

| Model | XMQ150×50 | XMQ150×100 | XMQ240×90 | XMQ350×160 |

| Drum Size (mm) | Φ150×50 | Φ150×100 | Φ240×90 | Φ350×160 |

| Capacity (g) | 200 | 400 | 1000 | 4000 |

| Feeding Size (mm) | ≤3 | ≤3 | ≤3 | ≤3 |

| Discharging Size (mm) | ≤0.074 | ≤0.074 | ≤0.074 | ≤0.074 |

| Power (kW) | 0.25 | 0.25 | 0.55 | 1.1 |

| Dimensions (mm) | 915×530×1160 | 915×750×1160 | 1050×640×1160 | 700×575×1190 |

| Weight (kg) | 90 | 130 | 170 | 300 |

Successful Cases

Contact Us Now

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours. Rest assured that we won’t reveal your information to anyone.