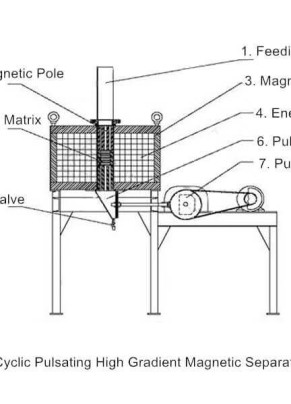

Cyclic Pulsating High Gradient Magnetic Separator

【Capacity】: 100-600 g/circle

【Ore-Feeding density】: 5-40 mm

【Ore Feeding Size】: -1.3(50~100) mm

【Application】: Apply for wet separation of weak magnetic metal ore, iron removal, and purification of non-metallic ores

Chat Online on WhatsApp

Chat Online on WhatsApp

Advantages

CGSL-100 cyclic pulsating high gradient magnetic separator (we call CGSL-100 for short below) is fit for the wet beneficiation of fine weakly magnetic metallic ore, which grain size is -1.3mm (-200mesh 50%~100%), such as iron oxide, manganese, wolframite and ilmenite, and the separation between wolframite and scheelite and that between wolframite and cassiterite, and deferrization and purification of the non-metallic ore such as quartz, feldspar, and kaolin. The machine feeds 100-600 grams of ore in each beneficiation cycle, which can be used for small-scale experiments in the laboratory or the preparation of a small number of mineral products.

CGSL-100 has two types that can reach the maximum background magnetic field strength of 1.2 Tesla and 1.75 Tesla.

Feature

- Equipped with a pulsation mechanism. Pulse frequency and background magnetic induction can be continuously adjusted within a wide range.

- High enrichment ratio.

- High beneficiation ratio.

- The matrix is challenging to clog.

- Strong adaptability to changes in feed particle size, consistency, and grade.

- Stable work, convenient operation & maintenance.

Product Structure

【Structure】

The CGSL-100 cyclic pulsating high gradient magnetic separator mainly consists of a feeding box, magnetic pole, magnetic yoke, energizing coils, magnetic matrix, pulsation mechanism, pulsation box, and valve.

【Working Principle】

Start the pulsation mechanism and adjust the feeding velocity and background magnetic induction to the needed value before doing the batch test. Adjusting the energizing current can control the background magnetic induction. A magnetic field will be built when giving electricity to the energizing coils. And the matrixes in the magnetic field are magnetized with a high gradient magnetic field formed around them. Feed the incompactly stirred slurry through the holes of the upper magnetic pole into the separating zone from the feeding box. The magnetic particles of the slurry can be attached to the surface of the matrix, and non-magnetic particles enter into the pulsation box by the holes of the lower magnetic pole and then are discharged. Put in some water for rinsing the concentrates to upgrade magnetic particles after each cycle of mine feeding is completed. Then shut off the energizing power and use clean water to wash out the magnetic particles to complete a batching test.

Technical Parameters

| Model | CGSL-100(Background Field 0~1.75T) | CGSL-100(Background Field 0~1.2T) |

| Separation Chamber D×H(mm) | Φ100×100 | Φ100×100 |

| Background Field(T) | 0-1.75 | 0-1.2 |

| Energizing Current(A) | 0~1900 | 0~1200 |

| Energizing Voltage(V) | 0~30 | 0~16.4 |

| Energizing Power(Kw) | 0~57 | 0~19.7 |

| Pulsating Power(Kw) | 0.75 | 0.55 |

| Pulsating Stroke(mm) | 0~30 | 0~30 |

| Pulsating Frequency(r/min) | 0~600 | 0~600 |

| Size of Ore-feeding(mm)

(-200 mesh %) |

-1.3(50~100) | -1.3(50~100) |

| Concentration of Ore-feeding (%) | 5~40 | 5~40 |

| Capacity (g/cycle) | 100~600 | 100~600 |

| Water Supply Pressure(MPa) | 0.1~0.3 | 0.1~0.2 |

| Dimensions L×W×H(mm) |

1800×800×1700 | 1600×800×1600 |

| Weight(kg) | 2500 | 2200 |

Successful Cases

Contact Us Now

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours. Rest assured that we won’t reveal your information to anyone.