Tin is a silvery-white metal with a strong luster, a relative density of 7.0, a low melting point (230 ℃), hardness of 3.75, soft and good ductility. The content of tin in the earth’s crust is only 2 × 10-6~3 × 10-6. Tin belongs to the cuprophilic element group, but it has the amphoteric characteristics of oxygen and sulfur in the upper lithosphere. Tin reacts with sulfur to form two compounds: Tin disulfide and tin disulfide, which are highly volatile at high temperatures. Tin can also combine with oxygen to produce tin oxide and tin dioxide. Although tin has divalent and tetravalent valence states, tetravalent compounds are relatively stable under natural conditions, especially tin oxide (SnO2), which is one of the most stable compounds in the earth’s crust.

There are more than 50 kinds of tin-containing minerals known in nature, and about 20 kinds of main Tin Minerals. Cassiterite is mainly of economic significance, followed by yellow tin ore. In some deposits, pyrite, antimony tin lead ore, cylindrical tin ore, sometimes black sulfur silver tin ore, black boron tin ore, Malayan stone, cassiterite, and magnesium tin ore can also be relatively enriched to form industrial value.

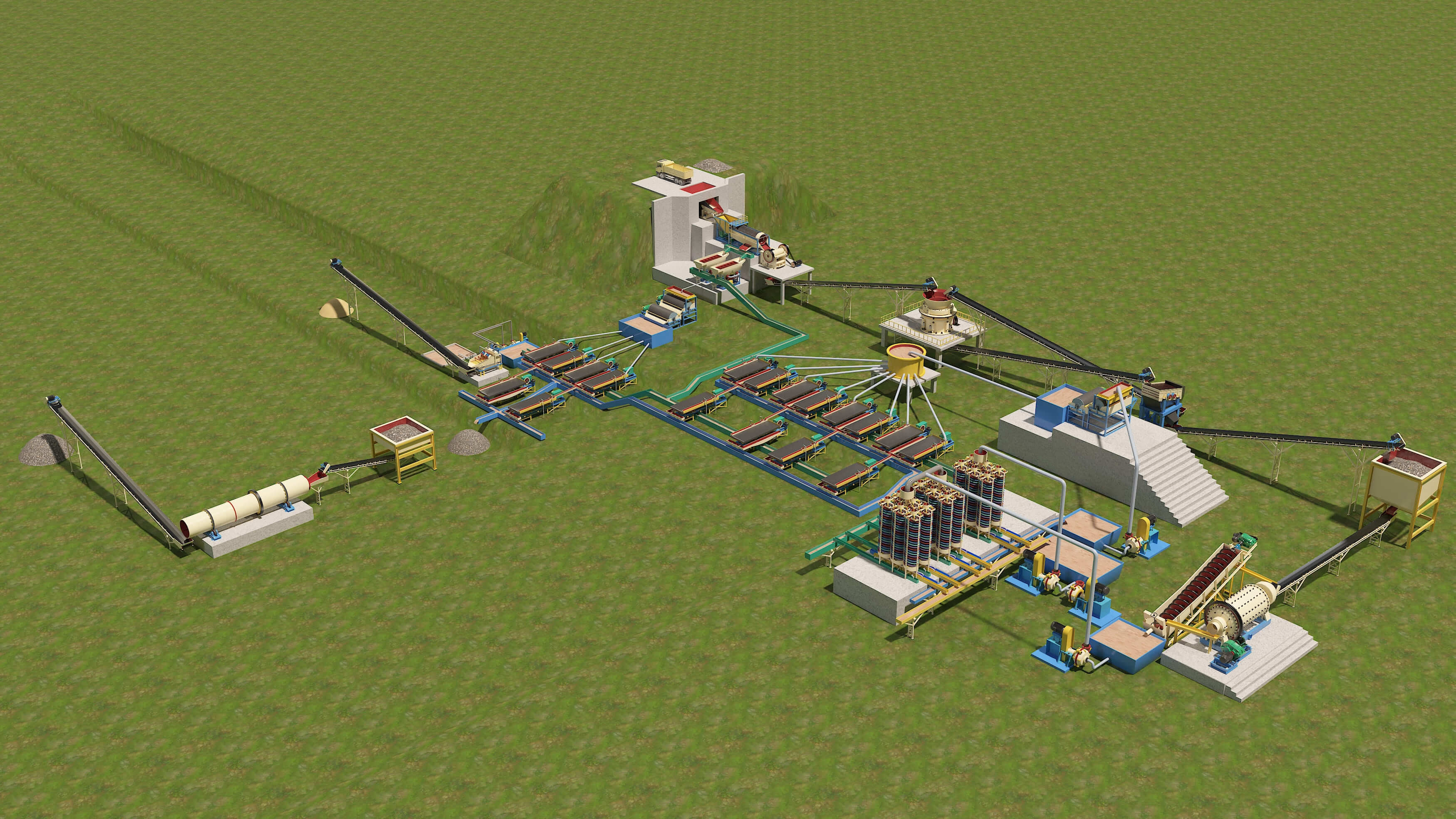

Tin Mining

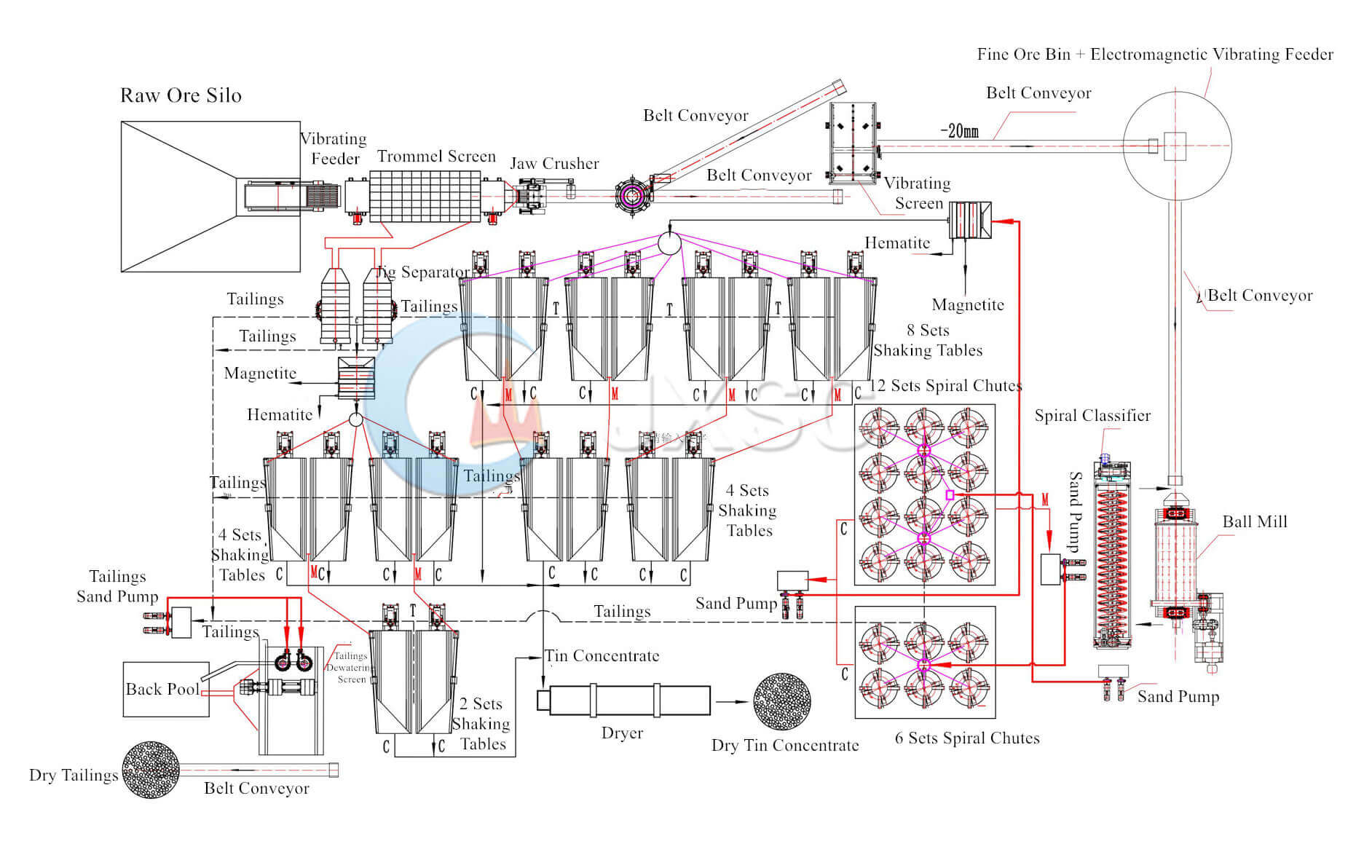

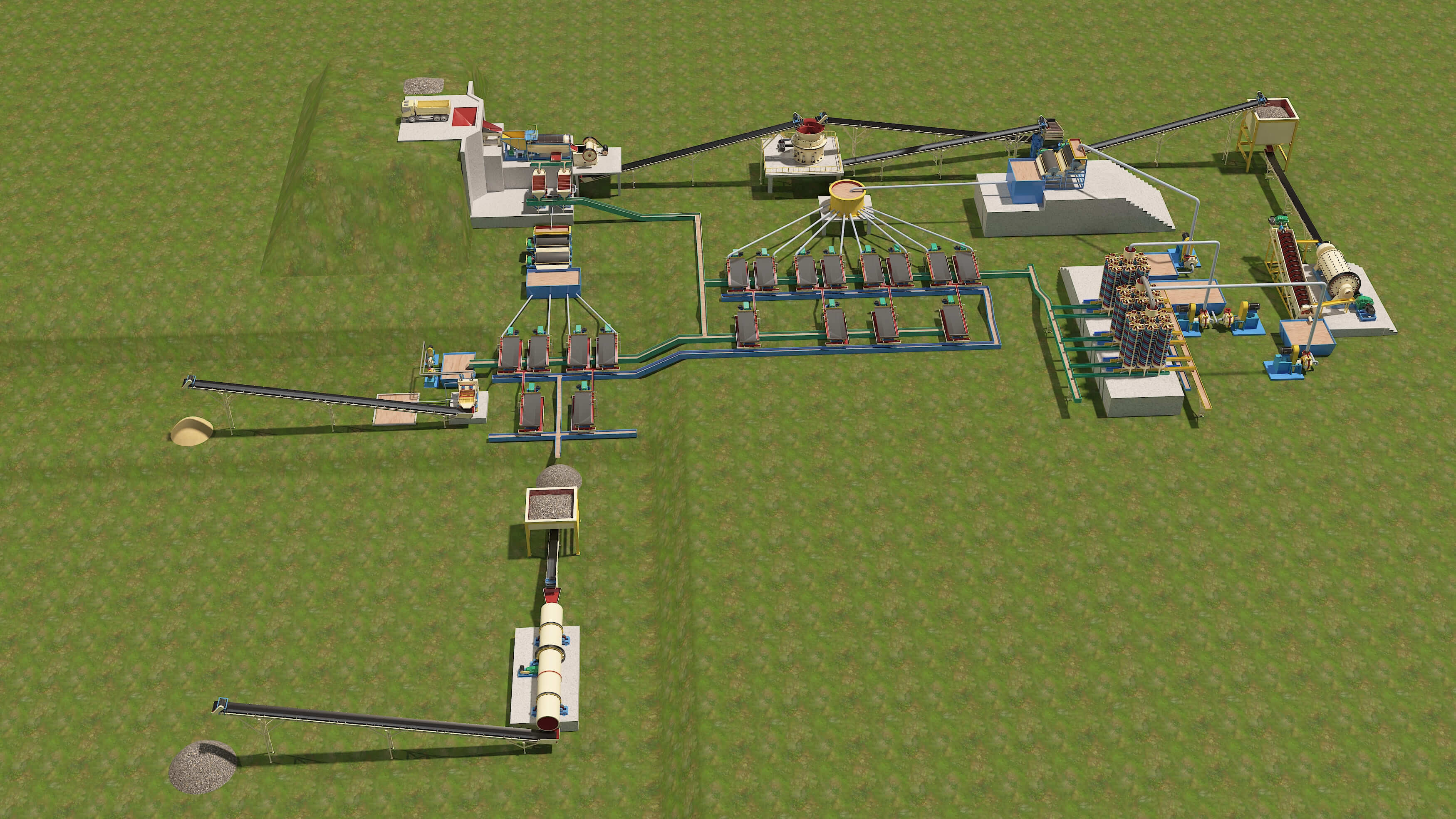

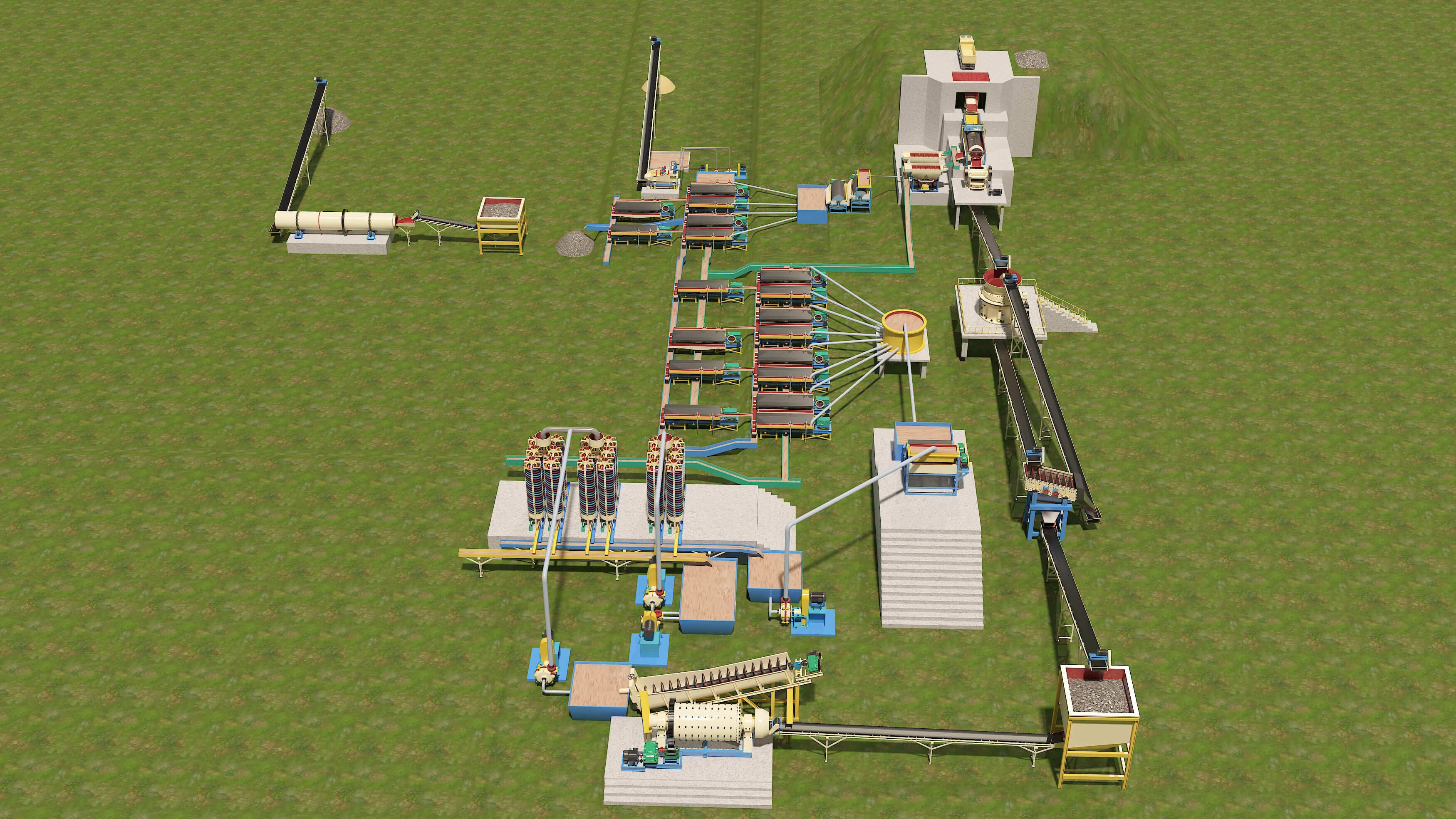

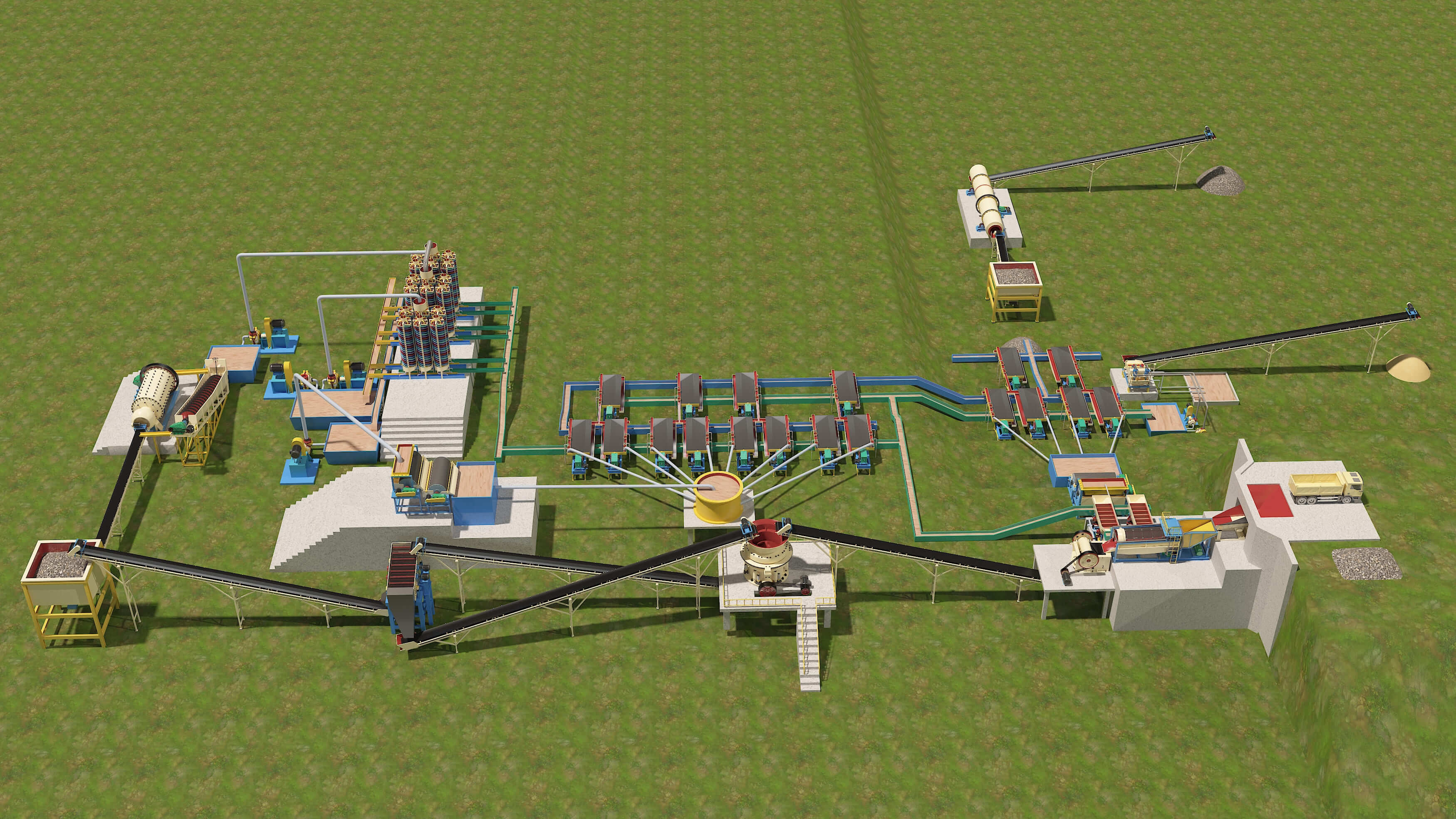

The beneficiation method of placer tin ore is similar to that of placer gold ore, which is generally treated by gravity separation method and equipment. For placer tin ore with high monomer dissociation, the beneficiation is basically the same as that of placer gold ore. better beneficiation indexes can be obtained through simple screening and washing. For placer tin ore with low monomer dissociation, rod grinding and other processes are often needed to break the continuous structure in order to improve the beneficiation recovery and concentrate grade.

The gravity separation of placer tin ore is also based on the principle of gravity beneficiation. It is sorted according to the specific gravity difference between tin and waste rock. Due to the large specific gravity difference between tin and waste rock in placer tin ore, a good beneficiation effect can be obtained by using gravity separation methods and equipment. At the same time, it has the advantages of high efficiency, energy-saving and environmental protection, small equipment investment, and low operation cost. It is an ideal choice for placer tin ore beneficiation.

The equipment for gravity separation of placer tin ore is mainly jig. Sometimes, in order to improve the recovery rate of fine-grained tin ore, a shaking table will also be used. The process flow of tin ore gravity separation is screening → jigging → dehydration. For placer tin ore with low monomer dissociation, it often needs to go through two gravity separation processes: screening → jig → rod mill → jig → dehydration. Gravity separation is the most ideal, economical, and effective tin ore dressing method. The sand tin ore gravity separation equipment has a small investment, low operation cost, and no pollution to the environment. The screening gravity separation method is used to treat the sand tin ore in major sand tin washing plants and tin mining ships. The beneficiation effect is good and the application is very common.