Kaolin Introduction

Kaolin is a non-metallic mineral, a kind of clay and clay rock dominated by kaolinite clay minerals. Because it is white and delicate, it is also called white cloud soil.

Kaolin minerals are composed of kaolinite cluster minerals such as kaolinite, dickite, pearlite, halloysite, etc. The main mineral component is kaolinite.

The crystalline chemical formula of kaolinite is 2SiO2·Al2O3·2H2O, and its theoretical chemical composition is 46.54% SiO2, 39.5% Al2O3, and 13.96% H2O. Kaolin minerals belong to the 1:1 type layered silicate. The crystals are mainly composed of silicon-oxygen tetrahedrons and aluminum hydroxide octahedrons. Among them, the silicon-oxygen tetrahedrons are connected in a two-dimensional direction to form a hexagonal arrangement by sharing a vertex angle. In the grid layer, the apex oxygen not shared by each silicon-oxygen tetrahedron faces one side; the apex oxygen of the silicon-oxygen tetrahedron layer and the oxygen-assisting octahedral layer forms a 1:1 unit layer.

Kaolin has a wide range of uses. It is mainly used in papermaking, ceramics and refractory materials, followed by coatings, rubber fillers, enamel glazes, and white cement raw materials, and a small amount is used in plastics, paints, pigments, grinding wheels, pencils, daily cosmetics, soaps, etc. Pesticides, medicines, textiles, petroleum, chemicals, building materials, national defense, and other industrial sectors.

Kaolin Recycling

Kaolin will produce a large number of tailings after ore dressing and recycling. As the recycling of kaolin tailings is less, with the continuous accumulation of tailings, it will encroach on a large amount of land, pollute water quality, and cause vegetation damage and soil erosion, and even cause Debris flow seriously affecting the ecological environment. Therefore, comprehensive utilization of kaolin tailings and recycling them can effectively prevent waste of resources and damage to the environment.

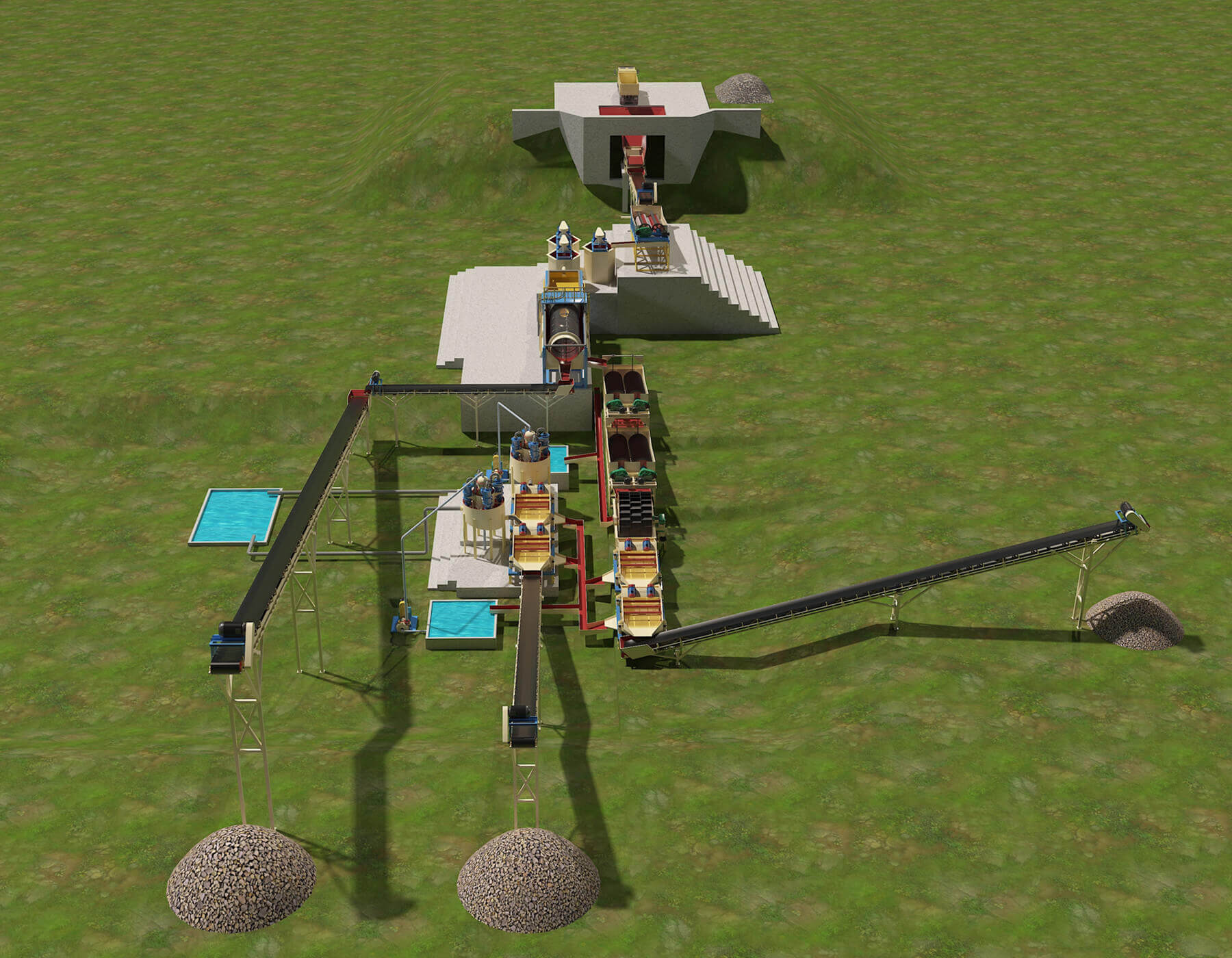

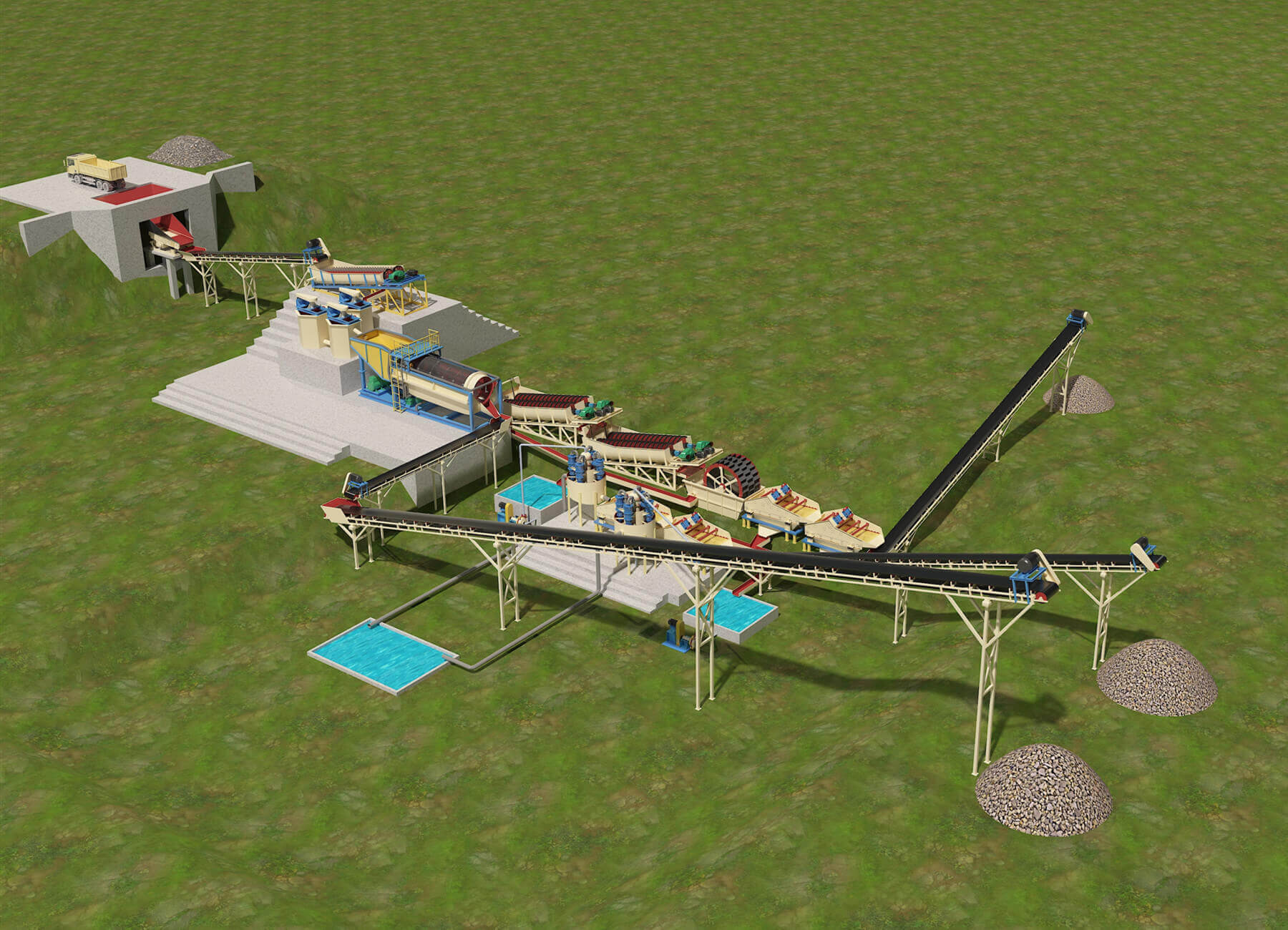

150tph Kaolin Recycling Process Plant

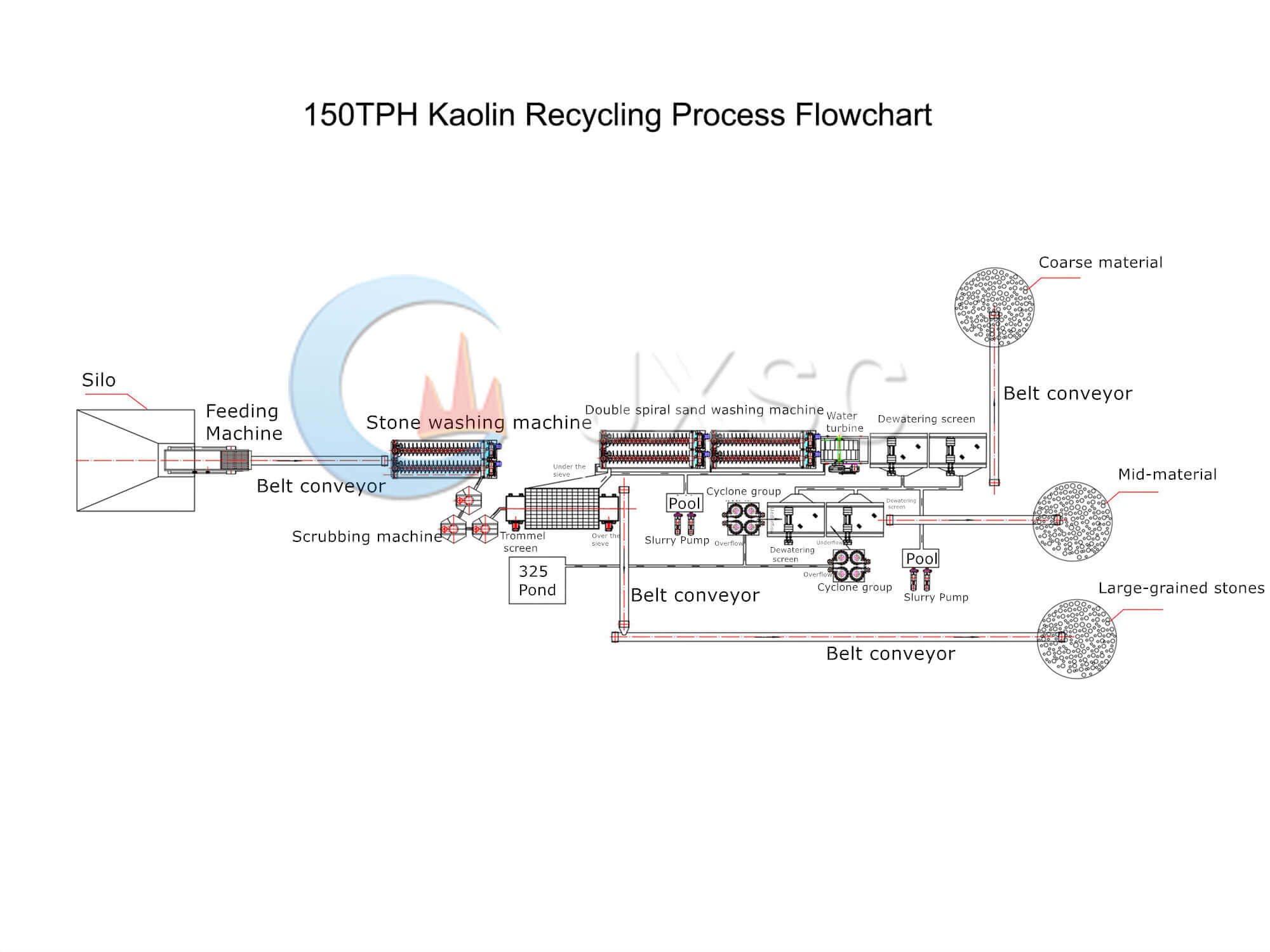

150TPH Kaolin Recycling Process Flowchart

Flowchart Explanation

- Use a forklift or excavator to feed the raw materials to the hopper, and a feeder below the hopper will evenly feed the raw materials to the belt conveyor, and the belt conveyor will send the raw materials to the log washer. The function of the log washer is to disperse, stir and clean the agglomerated kaolin clay.

- Enter the attrition scrubber for further cleaning. The function of the attrition scrubber is to better rub and fall off the sticky slime from the kaolin.

- After washing by the attrition scrubber, then enter the trommel screen to screen out big waste stones which are sent to far place by belt conveyor, and the material under the screen enters the double spiral sand washer.

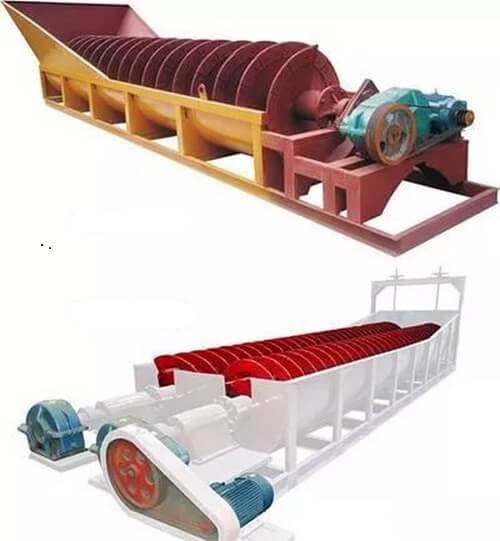

- The overflow of the first stage of the double spiral sand washing machine is kaolin concentrate, the underflow goes to the second stage of the spiral sand washer for again washing, the overflow of the second stage is kaolin concentrate, and the underflow goes to the wheel sand washer.

- The overflow from the wheel sand washer is the concentrate, the underflow goes to the dewatering screen.

- The under-screen materials of the first dewatering screen are the kaolin concentrate, the over screen materials go to the second dewatering screen for again dehydration, over screen materials of the second dewatering screen are coarse particles waste. Use a belt conveyor to send away, under the sieve is the concentrate.

Kaolin Concentrate under the screen of two dewatering screens into 2# pond.

Kaolin Concentrate from the overflows of the two spiral sand washers and wheel sand washer is into 1# pool. - Use the slurry pump to send 1# pond concentrate into 1# cyclone group, and the overflow of the cyclone group is kaolin concentrate, underflow flows to the dewatering screen for dehydration. and under the screen of the dewatering screen is a concentrate which goes into 2# pond. Over screen, materials are medium particles waste, which is transported away with a belt conveyor.

The under-screen concentrates of 4 dewatering screens are all in 2# pond, and they are pumped to 2# cyclone group with a slurry pump. The underflow of the 2# cyclone group goes to the dewatering screen, and the overflow is kaolin concentrate. - Finally, the overflow of the two cyclone groups (kaolin concentrate) will flow to the 325 concentrate pool.

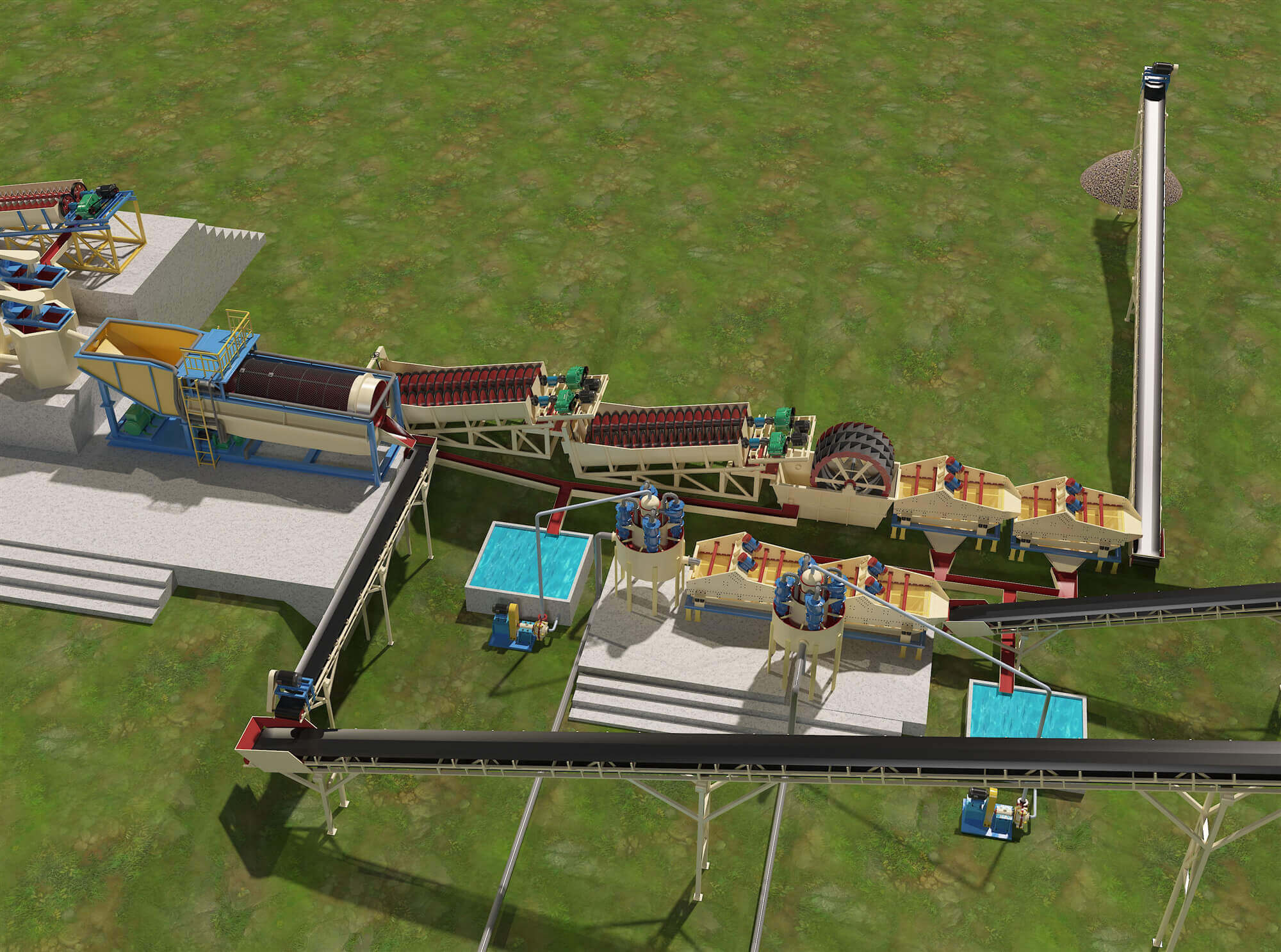

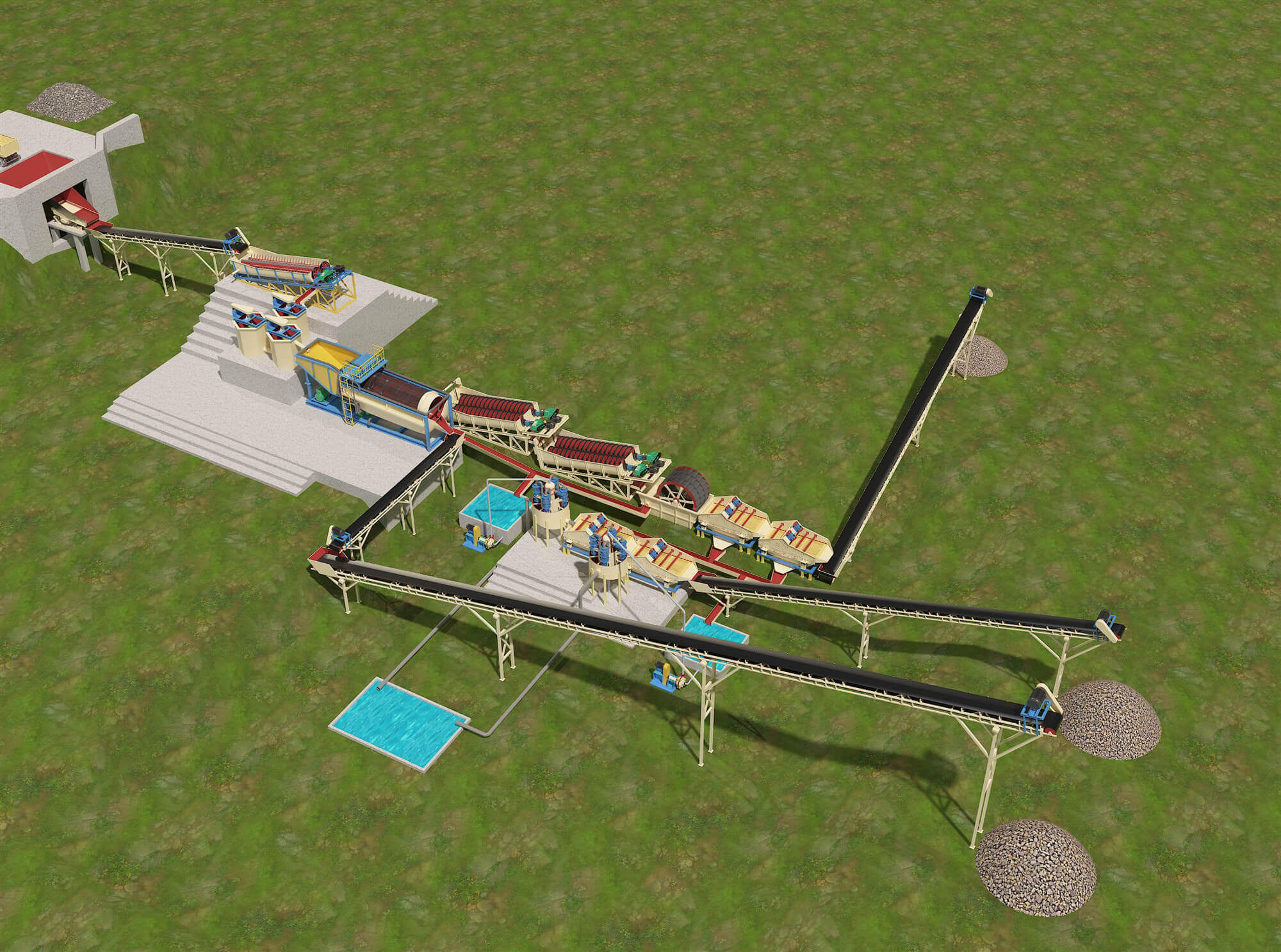

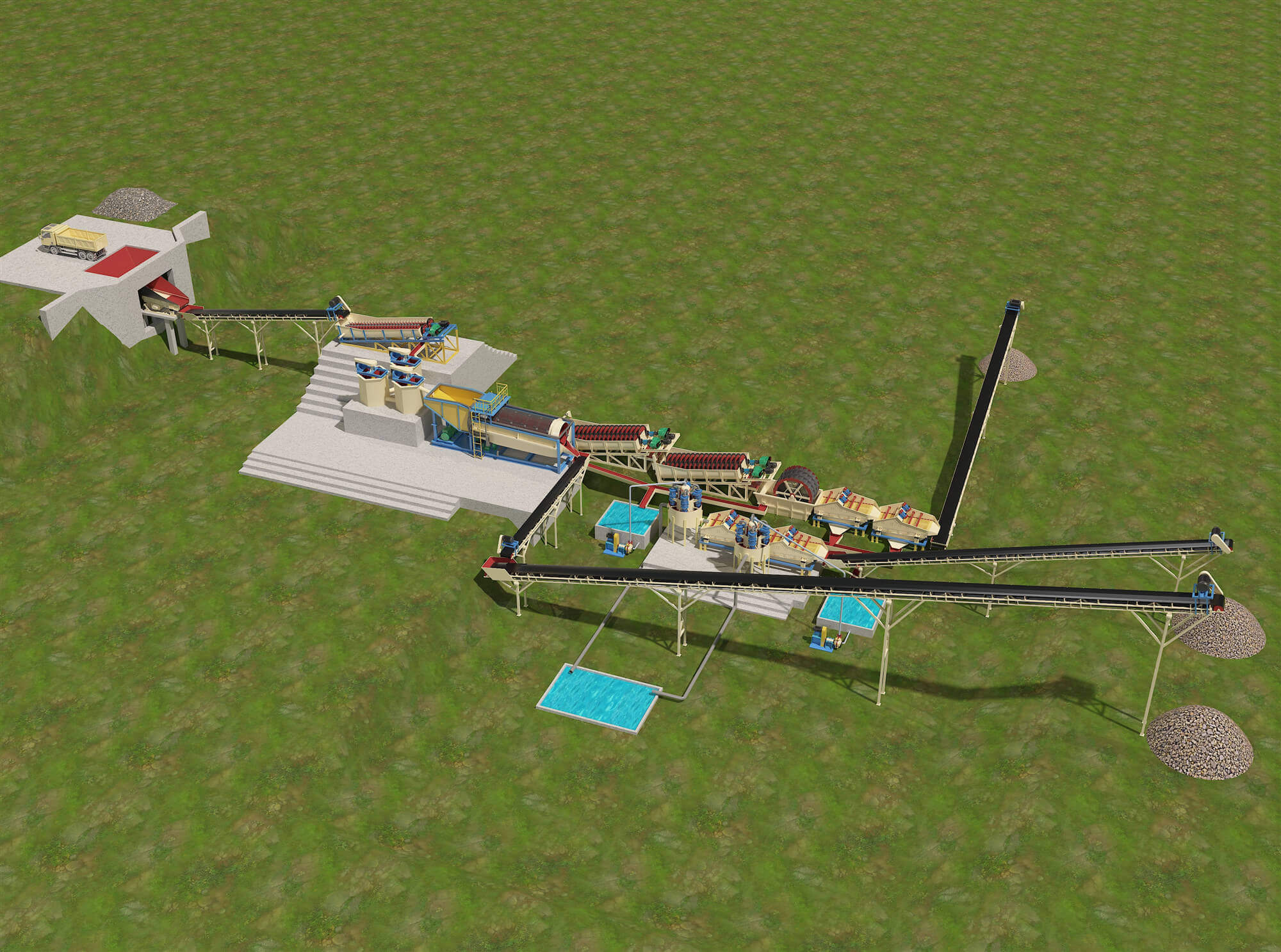

Kaolin Recycling Process Plant Layout

|  |  | ||

|  |  |

Main Machine Used in The Kaolin Recycling Process Plant

Spiral Sand Washer Spiral Sand Washer |  Trommel Screen Trommel Screen |  Slurry Pumps Slurry Pumps |

Conveyor Belt Conveyor Belt |  Hydrocyclone Hydrocyclone |  Dewater Screen |

LATEST PRODUCTS

Twin Screw Feeder

【Feeding Capacity】 10-160 t/h【Power】 2.2-…

Tubular Screw Conveyor

【Capacity】6-50 m3/h【Procesible Material】 …

Heavy Plate Feeder

Capacity: 100-240 m3/h Power: 15-45 kW Speed: 0…