Limestone Introduction

Limestone is a carbonate rock with calcite as the main component. Sometimes it contains dolomite, clay minerals, and clastic minerals, which are gray, gray-white, gray-black, yellow, light red, maroon, and other colors. The hardness is generally small, and there is a violent chemical reaction with dilute hydrochloric acid. It belongs to sedimentary rock according to its genesis.

The main component of limestone is calcium carbonate, which can be dissolved in water containing carbon dioxide. Generally, one liter of water containing carbon dioxide can dissolve about 50 mg of calcium carbonate.

The rock formed by the calcium carbonate deposited in the lake and sea after losing water is tightly pressed and cemented, which is called limestone. The mineral composition of limestone is mainly calcite (accounting for more than 50%) and some impurities such as clay and silt. The formation of most limestone is related to biological action. The limestone formed by the accumulation of biological remains includes coral limestone, shell limestone, algal limestone, and so on, which is generally called biological limestone. Limestone formed by the chemical precipitation of calcium carbonate (CaCO3) in an aqueous solution is called chemical limestone. Such as ordinary limestone, siliceous limestone, etc.

Limestone has excellent properties such as thermal conductivity, firmness, water absorption, airtightness, sound insulation, polishing, good cementation, and processability. It can not only be directly used in raw ore but also be deeply processed and applied.

Limestone is an important industrial raw material in metallurgy, building materials, chemical industry, light industry, construction, agriculture, and other special industrial sectors. With the development of the steel and cement industry, the importance of limestone will be further enhanced.

Limestone Crushing

Firstly, the raw materials are preliminarily crushed by the coarse jaw crusher, and then the produced coarse materials are transported by the belt conveyor to the impact crusher for further crushing. The finely crushed stones are sent to the vibrating screen to screen out three stones and stones of different sizes, and the oversized stones are returned to the impact crusher for crushing again.

The limestone crushing production process mainly includes 4 processes: feeding, crushing, screening, and transportation.

1. Feeding Process

At present, the vibrating feeder is commonly used in the industry. It evenly and continuously sends the stones in the raw material warehouse into the primary crushing equipment, and the performance of the whole process is stable and reliable.

2. Crushing Process

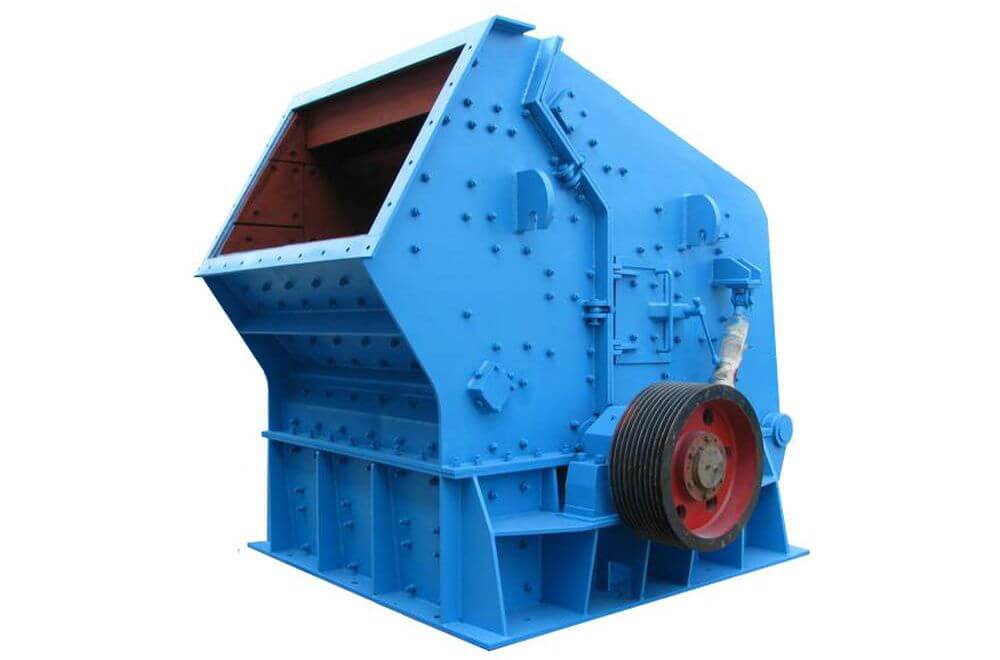

This process is divided into coarse crushing and medium and fine crushing. Jaw crusher is coarse crushing equipment, and impact crushing and cone crushing are mainly used for medium and fine crushing, but the softness of the crushed materials is different, so users should choose and configure according to the production situation.

3. Screening Process

The stone after crushing and sand-making need screening operation. This process can effectively control the size of finished products and screen out the sand and stone required by different industries.

4. Conveying Process

The belt conveyor runs through almost the whole process and is responsible for the conveying of materials in each process. It is essential supporting equipment in the limestone-crushing production line.

500TPH Limestone Crushing Plant

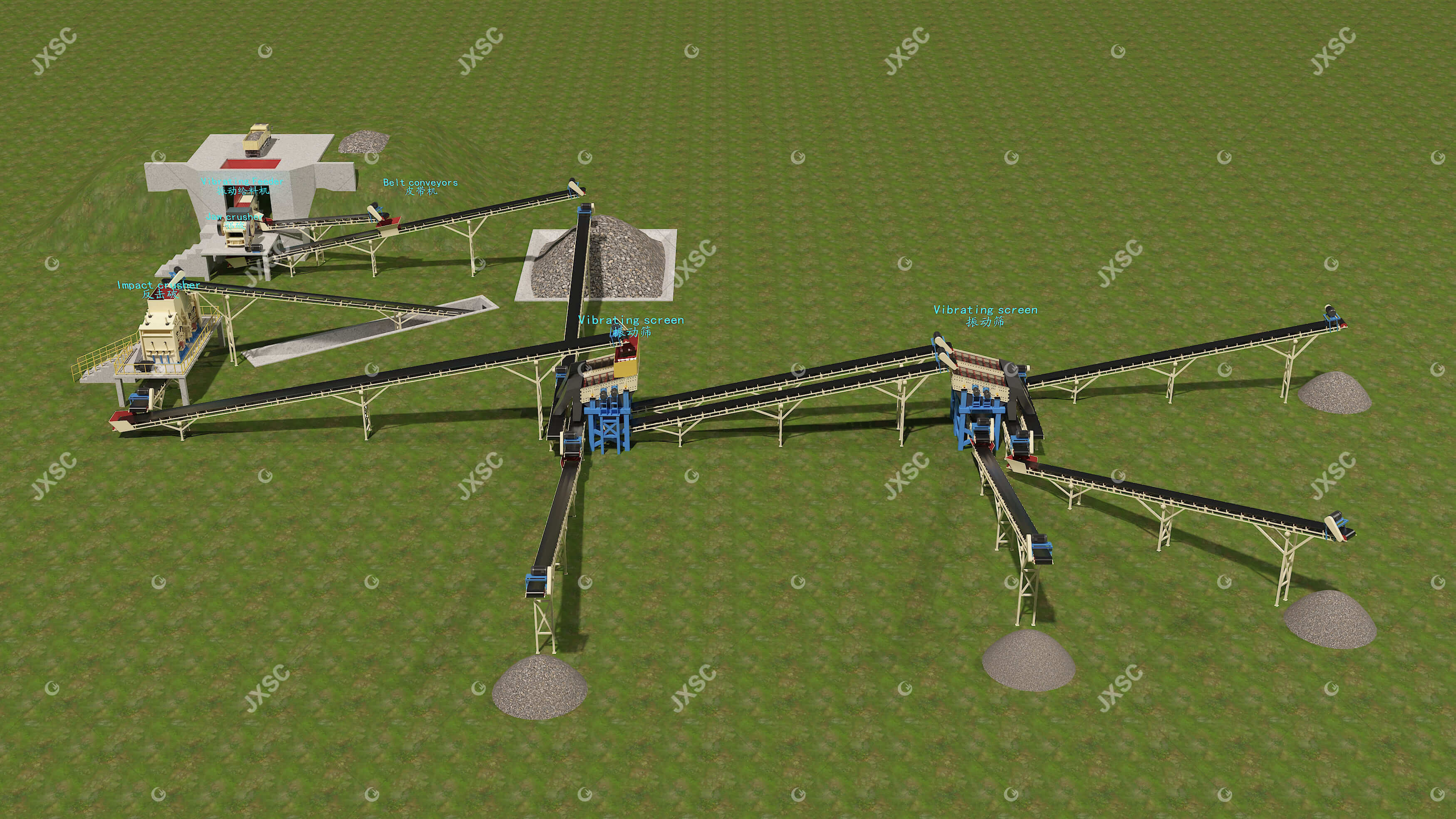

500TPH Limestone Crushing Plant Flowchart/Layout

This setup is a 500tph complete limestone crushing plant, the max input size is 1020mm, output sizes are 0-5mm, 5-19mm, 19-25mm,25-50mm.

It is configured with hopper, vibrating feeder DN6015, primary jaw crusher PE-1200*1500, 2 sets impact crusher PF1520,4 sets vibrating screen 2YD3072, and 12 pcs belt conveyors.

Flowchart Explanation

1. The Excavator unloads the stones into the hopper, the stone enters the vibrating feeder from the lower part of the hopper;

2. The vibrating feeder feeds the 120-1020mm stones evenly to the primary jaw crusher; the vibrating feeder will be with a gap 120mm grizzly bar. The 0-120mm stone will fall into the 1st belt. And it will be transferred to the 2nd main belt. And they will be transported to a stockpile.

3. The stockpile is equipped with one hoist vibrating feeder. The materials in the stockpile will be sent to the 3rd belt conveyor.

4. The material from the stockpile will be secondly crushed by the 2 sets PF1520. There is 4th conveyor belt which is under the 2 impact crushers.

5. The output of the impact crushers will be sent to two sets of vibrating screens 2YD3072 with 25mm, 50mm mesh by the 5th conveyors. The +50mm will be sent back to the stockpile to be crushed again by the 6th conveyor belt. And 25-50mm is the first product which will be transferred by the 7th conveyor belt.

6. The -25mm will be sent to another 2 sets of vibrating screens with 5mm, 19mm mesh by the 8th, 9th conveyor belt. After the screening, there will be three outputs 0-5mm, 5-19mm, and 19-25mm. Each output will need one separate conveyor belt.

Main Machine Used in The Limestone Crushing Plant

|  |  |  |

Related Crushing Plants

60TPH Limestone Sand Washing Plant in Morocco

75TPH Limestone Crushing Process in South Africa

LATEST PRODUCTS

Twin Screw Feeder

【Feeding Capacity】 10-160 t/h【Power】 2.2-…

Tubular Screw Conveyor

【Capacity】6-50 m3/h【Procesible Material】 …

Heavy Plate Feeder

Capacity: 100-240 m3/h Power: 15-45 kW Speed: 0…