Barite is a common mineral of barium, and its main component is barium sulfate (Bas04). It was produced in low-temperature hydrothermal veins, such as quartz-barite veins, donite-barite veins, etc., longer than galena, sphalerite, chalcopyrite, cinnabar, etc. Barite can also be produced in sedimentary rocks and appears as nodules. It is mostly found in sedimentary manganese deposits and muddy and sandy sedimentary rocks in shallow seas.

Barite Beneficiation Methods Introduction

As a mineral resource, barite requires beneficiation treatment before it can be used in various industries. The beneficiation methods of barite ore are mainly divided into two types: gravity separation and flotation.

Gravity Separation

The gravity separation method for selecting barite is mainly based on the large difference in specific gravity between barite and associated gangue. Gravity separation equipment separates minerals with different specific gravity to obtain barite concentrate with a larger specific gravity and barite tailings with a smaller specific gravity. The equipment used is mainly a jig concentrator.

Since the gravity separation method is used for beneficiation based on the specific gravity difference, and the beneficiation efficiency of fine-grained barite ores is not good, the gravity separation method is only suitable for mineral beneficiation of coarse-grained crystals with a certain specific gravity difference from associated gangue, such as fluorite-barite mines, quartz-barite mines, and other types of barite mines.

Flotation

The flotation method for barite ore beneficiation is mainly based on flotation differences between minerals. It has excellent beneficiation effects for donite-barite ore and calcite-barite ore. The equipment includes crushers, ball mills, classifiers, flotation machines, etc.

Since the flotation method requires the particle size of the ore to be within the particle size range suitable for flotation, and the particle size for flotation is mostly between 80 and 200 mesh, flotation is only used to process fine-grained crystalline low-grade barite mineral processing. It is also used for the flotation separation of barite-calcite with similar specific gravity.

Barite Beneficiation Equipment

Barite beneficiation equipment is divided into gravity separation equipment and flotation equipment. The gravity separation equipment mainly refers to the jig concentrator, and the flotation equipment is the flotation machine. Both of these two leading separation equipment require the use of crushers and vibrating screens. Conveyors and other auxiliary equipment, flotation also uses equipment such as ball mills, classifiers, and mixing barrels.

Barite gravity separation equipment mainly uses crushers, conveyors, and jigs to complete the separation of ores. Its mineral processing cost and equipment investment are relatively low. In contrast, barite flotation equipment uses crushers, conveyors, Ball mills, classifiers, mixing barrels, flotation machines, and other equipment with large operating costs and equipment investments. The barite mines in many provinces and regions in China are rich in coarse-grained barite. Good beneficiation process indicators can be obtained through simple gravity separation. Therefore, gravity separation equipment is widely used in barite beneficiation. Due to environmental protection requirements, equipment investment, and operating costs, flotation equipment has gradually been withdrawn from the field of barite mineral processing and replaced by gravity separation equipment.

80 TPH Barite Beneficiation Process Plant

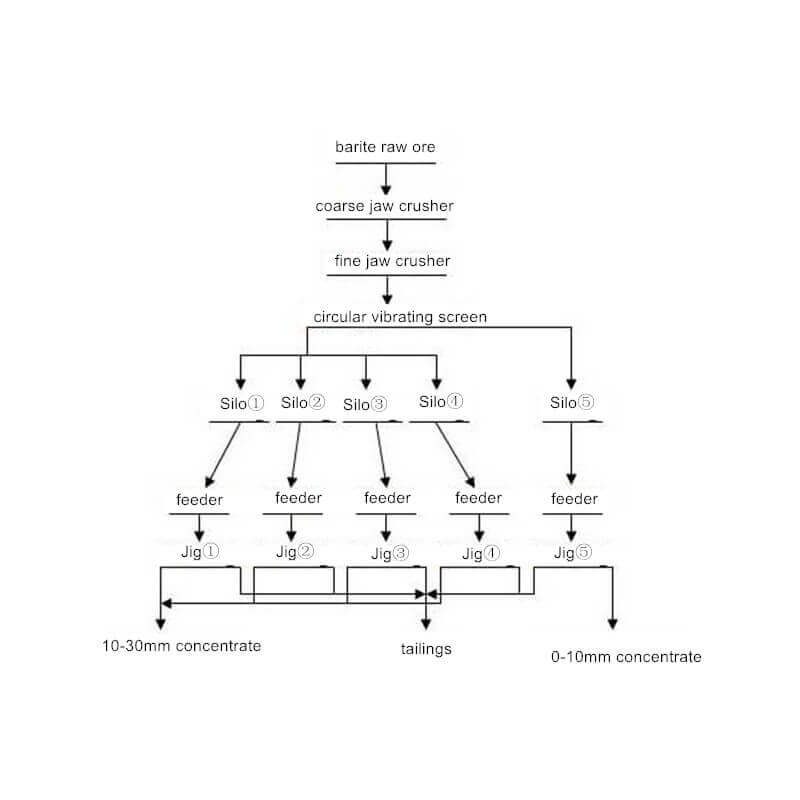

Barite Beneficiation Process Flowchart

Barite Beneficiation Process Introduction

The mineral processing process is a gravity separation process, and a jig is used as the main equipment for sorting and purifying barite ore. The process flow is described in detail below.

-

Crushing Process

Barite is brittle and brittle, so crushing mainly uses a simple and practical jaw crusher. A two-stage crushing process is used to crush the large pieces of barite mined to reach the effective selection range of the jig. It is recommended to use a PE400*600 jaw crusher for the first crushing stage and a PEF250*1000 fine jaw crusher for the second stage.

Transport the products after one-stage crushing to the second-stage fine jaw crusher via a belt conveyor for re-crushing to meet the particle size requirements of subsequent sorting equipment. Since the customer requires no dust during the production process, adding water appropriately during the crushing process is recommended to reduce the dust generated when the crusher works. -

Screening Process

Jig sorting has strict requirements on the particle size of materials and generally requires classification to achieve better beneficiation indicators and higher processing capacity. Therefore, a screening process needs to be set up in the barite gravity separation process to screen the crushed products. The broken products are divided into different particle sizes for separate processing and enter the jig machine for jig sorting.

The screening process adopts a simple and practical circular vibrating screen with a large processing capacity and high screening efficiency. This type of vibrating screen has a low failure rate, large processing capacity, high screening efficiency, and easy operation. It is an ideal equipment for barite ore screening. Since the screening process will also produce a certain amount of dust, it is recommended that water replenishment be installed during this process to reduce the generation of dust. -

Buffering Process

The normal operation of the jig requires a uniform and stable amount of ore, so it is best to set up buffering mechanisms and equipment before the jig, such as silos and vibrating feeders. The function of the silo is to avoid the work of the previous equipment. The quantity is sometimes large and sometimes small, and there is a certain amount of material in a moderate amount. The function of the vibrating feeder is to feed the jig material evenly and stably. The existence of these two auxiliary equipment is crucial to the normal and efficient operation of the subsequent jig.

No. 1-4 silos all use 15m’ silos, and No. 5 silos use 25m* silos. To facilitate transportation, we designed and produced the silos, which are combined detachable silos. The vibrating feeders all adopt a z3-type electromagnetic vibrating feeders. -

Jig Separating Process

We use two types of jigs to separate the crushed barite materials according to customer requirements. Since fine materials are inevitably produced during the crushing process, using two types of jigs is recommended. Separate coarse and fine materials separately. The D-④ jig uses a coarse-grained AM30 jig, which is used to process coarse-grained barite ore of 10-30mm. The No. 5 jig uses a 2LTC-6109/8T jig, which is used to process fine-grained barite ores of 0-10mm grain barite mine.

The concentrate produced by jig No. 1 to 4 flows into the 10-30mm particle size concentrate pool through pipelines or chutes, and the concentrate produced by jig No. 5 enters the O-10mm particle size concentrate pool. All tailings generated by jigs are collected into tailings ponds and transported away by forklifts or conveyors after settling. -

Dehydration Process

Since the customer requires mechanical dehydration, the dehydration process can use the simplest sedimentation dehydration. Adaptable mechanical dehydration solutions can also be designed according to requirements.

-

Water Circulation Process

Jig machines consume a lot of water and generally use circulating water for operation. Therefore, a water circulation plan needs to be designed according to the specific conditions of the customer’s site to ensure the normal and effective progress of the process.

80 TPH Barite Beneficiation Equipment

| Equipment | Model | QTY |

| Jaw crusher | PE400*600 | 1 |

| Jaw crusher | PEF250*400 | 1 |

| Jaw crusher | PEF250*1000 | 1 |

| Impact crusher | PF1007 | 1 |

| Circular vibrating screen | 2YZ1545 | 1 |

| Jig concentrator | AM30 | 4 |

| Jig concentrator | 2LTC-6109/8T | 1 |

| Belt conveyor | 800 | – |

| Belt conveyor | 650 | – |

| Feeder | GZ3 | 5 |

| Silo | 25m3 | 1 |

| Silo | 15m3 | 4 |

LATEST PRODUCTS

-

Tubular Screw Conveyor

【Capacity】6-50 m3/h 【Procesible Material】 …

-

Heavy Plate Feeder

Capacity: 100-240 m3/h Power: 15-45 kW Speed: 0…

-

Plate Magnetic Separator

【Capacity】8-35 t/h 【Power】1.5-3 kW 【Applic…