Ball and rod mills are widely used grinding equipment in mineral processing plants. The two are similar in appearance and grinding principle, but there are differences in structure, performance, use, etc. This article will introduce their similarities and differences and tell you how to choose a ball mill and a rod mill.

The Similarities Between Ball Mill And Rod Mill

Appearance: From the appearance, the ball mill and rod mill are both long cylinder-mounted equipment styles.

Classification: Ball mills and rod mills are both key grinding equipment for crushing materials after crushing.

Structure: The structure is the same. They are all horizontal cylinder structures. The cylinder is equipped with grinding media, feeders, large and small gears, feed end, discharge end, transmission device, etc.

Principle: The working principles of ball and rod mills are the same. Both drive the cylinder to rotate through the transmission device. After the grinding medium is raised to a certain height, it is completely dropped at a specific linear speed. Under force, the grinding medium is The materials are impacted, ground, and extruded to achieve the grinding function.

The Difference Between Ball Mill And Rod Mill

Appearance and structure

Although the appearance of ball mills and rod mills are very similar, the proportions of the two cylinder shapes are different. The ratio of the barrel length to the diameter of the ball mill is small, usually equal to 1 or slightly greater than 1; the ratio of the barrel length to the diameter of the rod mill is maintained between 1.5-2.0, and the inner surface of the liner on the end cover is a vertical plane state. In addition, the speed of the rod mill cylinder is lower than the working speed of the ball mill of the exact specification so that the medium in the rod mill works in a cascading state.

Ore discharge method

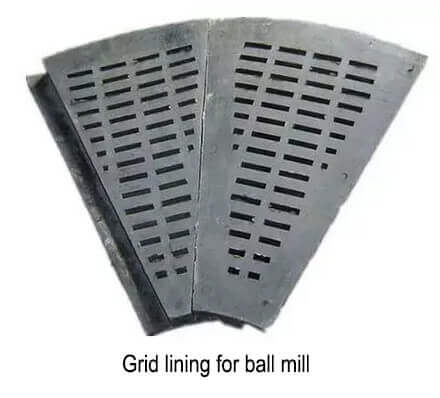

Ball mills can be divided into overflow-type and grid-type, while rod mills are classified into overflow-type and open-type rod mills.

Among ball mills, the commonly used ones are grid-type ball mills and overflow-type ball mills (named from different structures of the ore discharge parts), while rod mills do not use grid plates to discharge ores, and they only have two types: overflow-type and open type. The diameter of the end center shaft is generally larger than that of ball mills of the exact specification.

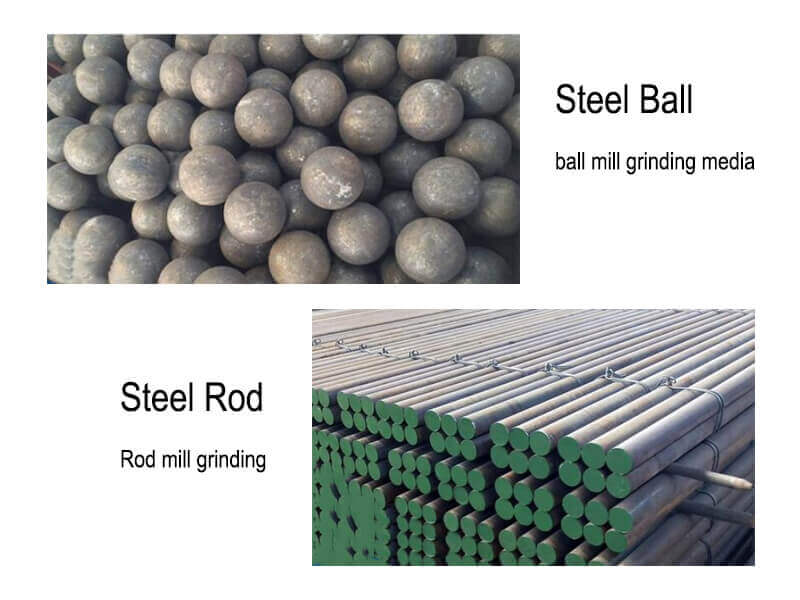

Grinding media

The grinding medium of a ball mill is steel balls, while the grinding medium of a rod mill is steel rods. The difference in grinding body is the most important difference between the two.

Because the grinding bodies are different, their working methods also have their characteristics. There is point contact between the steel balls of the ball mill and the material; there is line contact between the steel rods of the rod mill and the material. The gaps between the rods are regular strips with a specific screening effect on the material.

Grinding media filling rate

The grinding medium’s filling rate refers to the grinding medium’s percentage accounting for the grinding mill’s internal volume. The filling rate of the ball mill is usually 40%-50%; the filling rate of the rod mill is 35%-45%. Too high or too low the filling rate of grinding media will affect the grinding effect.

Performance analysis

The performance characteristics of the ball mill are high production capacity, strong adaptability to materials, and relatively high fineness of materials. Usually, the discharge degree is between 0.074~0.4mm, the discharge particle size is acceptable, easy to grind, and the energy saving is relatively significant. However, the over-crushing phenomenon of the ball mill is serious.

The characteristics of the rod mill are that the product is relatively rough. Still, the particle size is uniform, containing less coarse sand and sludge, and the over-grinding is lighter. The discharge particle size is usually between 0.833~0.147mm, and the particle size characteristics of the rod mill product differ from those of the rod mill. It is related to the condition of the ore.

Stability analysis

The stability of the ball mill is relatively good. Because the ball mill has no inertial impact during operation, it ensures that the equipment can operate normally and efficiently, reduces equipment downtime, and improves production efficiency.

Scope of use

When gravity or magnetic separation of metal ores (such as tungsten tin ore and rare metal ores), rod mills are often used to prevent over-crushing; it is also suitable for brittle materials, such as coal; in the second-stage grinding process; generally, a rod mill is used as the primary grinding equipment, which has larger production capacity and higher efficiency. A rod mill can be used instead of a short-head cone crusher for fine crushing when processing softer or less complex ores. It is simple in configuration and low in cost and can simplify dust removal in the work workshop.

The ball mill has a broader application range, and metals, non-metals, or stones can be used for grinding. However, over-crushing can quickly occur due to the fine grinding materials, so gravity separation production lines in metal mineral processing are unsuitable.

How To Choose a Ball Mill and a Rod Mill?

Understanding the differences between ball and rod mills lays the foundation for equipment purchase. Generally speaking, users can choose based on their raw materials, finished product particle size and effect, production methods, etc.

According to raw materials

If the raw materials are brittle materials such as tungsten tin ore, rare metal ores, and coal, choose a rod mill; if the materials are aluminum ash, lime, slag, molybdenum ore, etc., use a ball mill. It is relatively better to deal with it.

According to the particle size effect of the finished product

- The product particle size is 1~3mm. When used for rough grinding, choose a rod mill.

- The product particle size is less than 0.5mm. When used for fine grinding, choose a ball mill.

The product of the rod mill is rougher but more uniform than the ball mill’s.

According to the production method

In the gravity separation or magnetic separation of rare metals, in order to prevent the harm caused by excessive powder during the operation, rod mills are usually used for material grinding; ball mills are mostly used for production and processing in cement plants.

JXSC machine warmly reminds us that when selecting grinding equipment, we should consider multiple aspects and choose appropriate grinding equipment according to different demand scenarios to ensure that the grinding equipment matches the process flow and avoids economic losses.

LATEST PRODUCTS

Twin Screw Feeder

【Feeding Capacity】 10-160 t/h【Power】 2.2-…

Tubular Screw Conveyor

【Capacity】6-50 m3/h【Procesible Material】 …

Heavy Plate Feeder

Capacity: 100-240 m3/h Power: 15-45 kW Speed: 0…