In nature, copper ore generally contains a mixture of copper sulfide and copper oxide. Concentrators usually use flotation to improve ore grade so they can smelt pure copper later.

Common main copper oxide minerals are

- Malachite (CuCO3-Cu(OH)2, containing 57.4% copper, density 4g/cm3, hardness 4).

- Azurite (azurite, 2CUCO3.Cu(OH)2, containing Copper 55.2%, density 4g/cm3, hardness 4).

- hrysocolla (CuSi03-2H20, copper 36.2%, density 2~2.2g/cm3, hardness 2~4).

- Cuprite (CU20, copper 88.8%, density 5.8~6.2g/cm3, hardness 3.5~4).

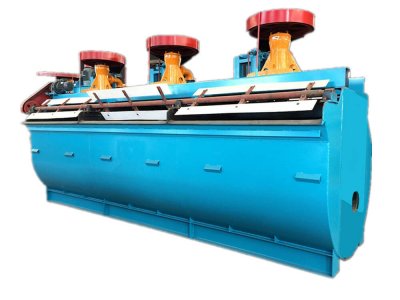

Flotation is the main separation method of modern copper oxide ore. It can divide into direct flotation and sulfide flotation according to the different properties of copper oxide ore. Copper sulfide ore mainly includes single and polymetallic copper sulfide ore. The flotation process of single copper sulfide ore is generally simple, and the flotation process of polymetallic copper sulfide ore is more complicated. A variety of mining equipment is used in the process of flotation of copper ore. Below we introduce you to the leading equipment used in it.