Geology of Diamond ore:

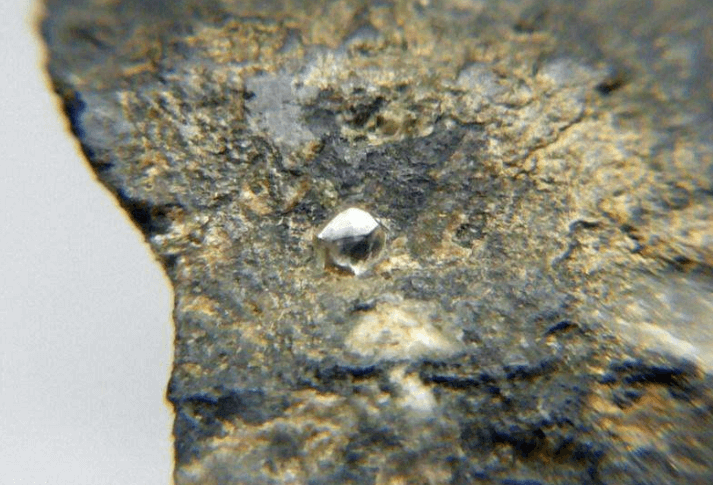

Diamonds ore are extremely rare, with concentrations of at most parts per billion in source rock. most diamonds were found in alluvial deposits. Loose diamonds are also found along existing and ancient shorelines, where they tend to accumulate because of their size and density.

Rarely, they have been found in glacial till (notably in Wisconsin and Indiana), but these deposits are not of commercial quality. These types of deposit were derived from localized igneous intrusions through weathering and transport by wind or water.

Most diamonds come from the Earth’s mantle, and most of this section discusses those diamonds. However, there are other sources. Some blocks of the crust, or terranes, have been buried deep enough as the crust thickened so they experienced ultra-high-pressure metamorphism. These have evenly distributed microdiamonds that show no sign of transport by magma.

A common misconception is that diamonds are formed from highly compressed coal. most diamonds that have been dated are far older than the first land plants. It is possible that diamonds can form from coal in subduction zones, but diamonds formed in this way are rare, and the carbon source is more likely carbonate rocks and organic carbon in sediments, rather than coal

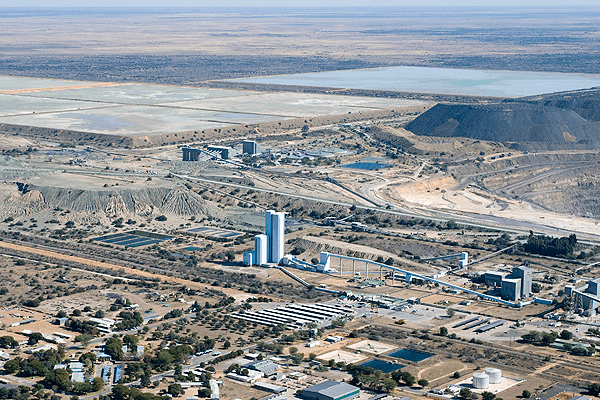

The world’s Top 10 Biggest Diamond mines :

The 10 largest diamond mines in the world by measurable reserves contain more than one billion carats of recoverable diamonds. Russia is almost half of the world’s biggest diamond mines, while Botswana has two mines; including the world’s largest diamond producing mine Orapa. Details as below:

- Jubilee, also known as the Yubileyny diamond mine, located in Sakha (Yakutia), Republic of Russia, is the biggest diamond mine in the world.

- The Udachny diamond mine, also located in the Yakutia region of Russia, ranks as the world’s second largest diamond mine by reserve size.

- Mir or Mirny, another diamond mine in the Yakutia region of Russia, is the third biggest diamond mine in the world.

- Argyle diamond mine located in the Kimberley region of Western Australia ranks as the world’s biggest diamond mine if JORC reserves alone are taken into account.

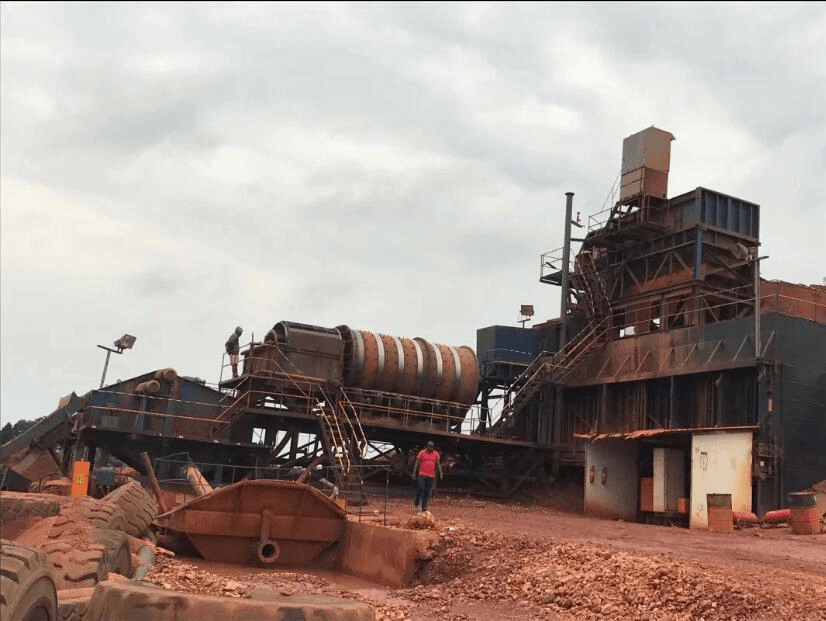

- Catoca diamond mine in Angola ranks as the fifth biggest diamond mine in the world.

- Venetia diamond mine located 80km from Musina in Limpopo Province of South Africa ranks as the world’s sixth largest diamond mine.

- Grib diamond mine, which is yet to commence commercial production, is Russia’s fourth largest and world’s seventh largest diamond mine.

- Jwaneng diamond mine in African country Botswana ranks as the eighth biggest diamond mine in the world.

- Orapa diamond mine located 240km west of Francistown city in Central Botswana is the ninth largest diamond mine in the world by reserve.

- Botuobinskaya diamond mine, due to commence production in 2015, is located in the Nakyn kimberlite field, around 200km north-west of Nyurba in the Yakutia region of Russia.

Other countries that produce diamonds include Congo (gold), Brazil, Guyana, Venezuela, Central Africa, Garner, Guinea, Ivory Coast, Liberia, Namibia, Sierra Leone, Tanzania, Zimbabwe, Indonesia, India, China, Canada and so on.