The main products of mercury ore are mercury and cinnabar. China’s mercury ore is mainly mercury. And cinnabar is used in chemical medicine. The mining of liquid mercury is relatively simple. Here we mainly introduce the mining and purification methods and technological process of cinnabar “cinnabar.” Cinnabar is a red mercury sulfide mineral with a specific gravity of 8.1-8.2 and good natural flotation. The beneficiation methods are mainly flotation and gravity separation; sometimes, they use combined gravity separation and flotation for processing.

The mercury process plant is a production line for the beneficiation and purification of mercury ore. However, the beneficiation methods and processes are also different according to different mercury ore types. Therefore, it divided the mercury ore beneficiation plant into various kinds. There are gravity-separation production lines, flotation production lines, and combined gravity-flotation production lines.

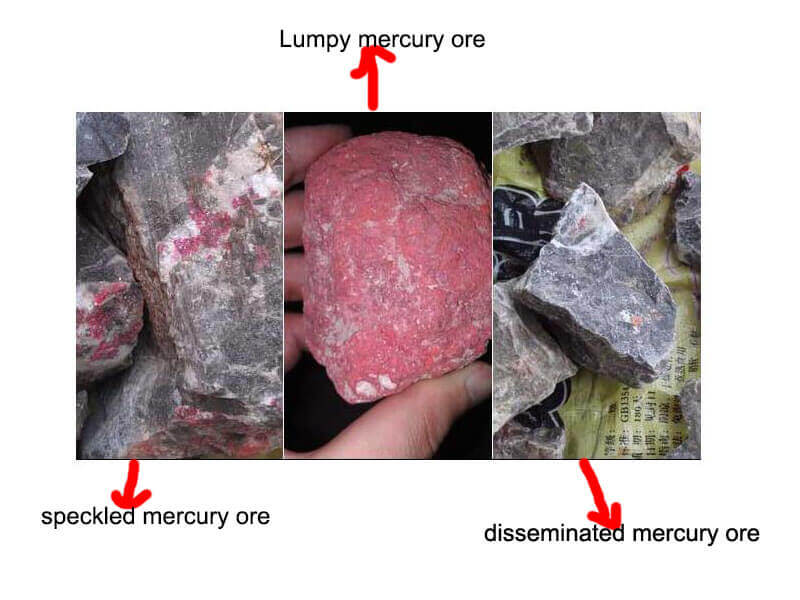

Mercury Ore Types

The structure of mercury ore is relatively complex, including disseminated, speckled, and massive. We can use single gravity separation for massive mercury ore beneficiation to obtain higher indicators. Use flotation for disseminated mercury ore beneficiation to get a high beneficiation index. And use the combined gravity separation and flotation process for speckled low-grade mercury ore beneficiation.

How to Beneficiate Different Types of Mercury Ore?

Massive mercury ore and speckled mercury ore: The beneficiation is very simple. Accord hand selection and gravity separation can get good beneficiation indicators. Sometimes, in order to reduce production costs and improve the mineral processing index, speckled mercury ore is also treated by gravity separation-flotation combined process. The gravity separation process discards a large amount of waste rock in advance on the premise of ensuring the recovery rate, reduces the cost and equipment investment of subsequent grinding and flotation, and improves the effective working speed of the subsequent process. The flotation method is used to purify the coarse gravimetric concentrate to obtain the final product. And this process is most suitable for the beneficiation of speckled mercury ore.

Disseminated mercury ore: Due to the mutual dissemination of mercury minerals and waste rock, It must grind disseminated mercury ore to break the conjoined organisms to extract mercury minerals. However, the particle size of the ground mercury minerals is very fine, and the gravity separation method can no longer be processed. Even so, flotation of lower-grade mercury ore still has high economic returns due to the higher added value of mercury ore.

The manual separation method is based on the difference in color, shape, and other characteristics between mercury ore and waste rock. It has the features of low production cost and high concentrate grade features, but it can’t be used for the beneficiation of medium and fine-grained mercury ores. The indicators are also unstable, and the labor intensity of workers is relatively high. The gravity separation method is suitable for processing speckled mercury ore and coarse-grained embedded mercury ore. It has the advantages of high beneficiation efficiency, small equipment investment, low operating cost, and no environmental pollution. Ore recovery is low. The flotation method is mainly used to extract disseminated mercury ore. Due to the high floatability of mercury sulfide ore, the flotation method often can achieve higher beneficiation indicators. And the purity and recovery rate of concentrate can meet the ideal requirements. Because the equipment of the flotation process investment is large, it has high operating costs and certain environmental pollution.

Mercury Ore Beneficiation Process

The mercury ore beneficiation process is mainly divided into the gravity separation process, the flotation process, and the gravity separation-flotation combined process.

- The mercury ore gravity separation process is crushing – screening – jigging – shaking table.

- The mercury ore flotation process is crushing-screening-grinding-classification-stirring-flotation-filtering.

- The combined process of mercury ore gravity separation and flotation is: crushing – screening – gravity separation – dehydration – grinding – classification – stirring – flotation – filter press.

Mercury ore beneficiation equipment

In the process of mercury separation, the equipment we usually use in the gravity separation includes the shaking table and jig concentrator. The jig concentrator handles coarse-grained ore, and the shaking table handles fine-grained ore. The flotation process we use is a flotation machine.

Shaking Table

The shaker tables are divided into coarse sand shakers, fine sand shakers, and ore mud shakers.

The feeding particle size of the coarse sand shaker can be 2mm, the feeding amount per hour is between 30-60 tons, and the feeding concentration is 25-30%.

The feeding particle size of the fine sand shaker can be 0.5mm, the feeding amount per hour is between 10-20 tons, and the feeding concentration is 20-25%.

The ore-feeding particle size of the slime shaker can be 0.15mm, the ore-feeding rate is 15-25 tons per hour, and the ore-feeding concentration is 15-25%.

Jig Concentrator

There are three types of jig concentrators: aside-moving, downward-moving, and side-moving. Different models and styles have different feeding granularity and processing capacity per hour. If you want to know the details, you can consult with the sales engineer.

Flotation Machines

There are two types of flotation cells: air-filled stirring flotation cells and mechanically stirring flotation cells.

The models of mechanical stirring flotation machines are XJ, JJF, XJQ, SF, ring-shot, etc.;

The models of air-filled stirring flotation machines are CHF-X, BS-X, XJC, KYF, XCF, BS-K, etc.

LATEST PRODUCTS

Twin Screw Feeder

【Feeding Capacity】 10-160 t/h【Power】 2.2-…

Tubular Screw Conveyor

【Capacity】6-50 m3/h【Procesible Material】 …

Heavy Plate Feeder

Capacity: 100-240 m3/h Power: 15-45 kW Speed: 0…