Ball mill steel balls are consumables of the grinding plant, milling balls need to be replenished at intervals to ensure the grinding quality and grinding rate. How many balls in a ball mill can obtain the best grinding efficiency? Let’s figure out.

If you would like the ball mill price, contact us, quick respond!

Significance of ball mill balls

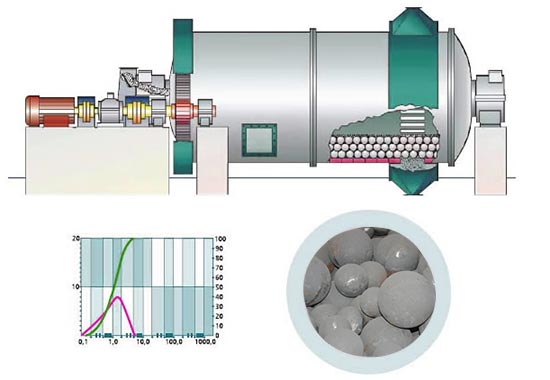

The ball mill is one of the necessary equipment for the mine beneficiation plant, and the investment in the ball mill accounted for a large proportion of the entire beneficiation plant. The ball mill balls’ quality, quantity, and size will all affect the grinding effect of the ball mill. In addition, while grinding the ore block, the steel balls continuously wear and become smaller until it fails, so the grinding balls’ consumption is extremely large.

If the ball mill is loaded with too many grinding balls, the steel balls are easily overlapped with each other, and the grinding effect is lost. Moreover, some of the steel balls are thrown before the height is raised, which reduces the grinding capacity as a whole and increases the power of the ball mill. If the ball mill contains too few balls and there is not enough capacity between the steel balls to grind the material, it will prolong the working time of the ball mill, which will not only consume a lot of energy, but also cause low grinding efficiency. Therefore, the rationality of ball mill ball loading Very important.

How many balls

In general, the ball volume of the ball mill steel ball is lower than the horizontal line in the cylinder. It is better to control the ball amount at about 40-50%. For smaller ball mills, the ball balls accounts about 35% at best, this can effectively ensure that the steel ball can fall freely, so that creates a larger impact force.

Ball mill steel balls mainly include: cast iron balls, forged steel balls, rolled steel balls, and the diameter of ball mill steel balls usually is Φ20mm ~ Φ120mm, and the maximum steel ball diameter used by super large ball mill is Φ130mm ~ Φ150mm.

How to add milling balls proportionately

Generally, the newly installed ball mill has a running-in process. During the running-in process, the amount of steel balls is added for the first time, which accounts for 80% of the maximum ball load of the ball mill. Steel ball sizes are Φ120㎜, Φ100㎜, Φ80㎜, Φ60㎜, Φ40㎜.

For example, the 100-150 tons ball mill has a maximum ball loading capacity of 9.5-10 tons. For the first time, 30% – 40% of the steel balls (120mm and 100mm), 40% – 30% of the medium balls (80mm) and 30% of the small balls (60mm and 40mm) were added.

Why only 80% of steel balls are added in the running in process of the ball mill? Because after the ball mill is installed, the large and small teeth of the ball mill need to mesh, and the handling capacity (ore volume) should be gradually increased. After two or three days of normal continuous operation of the ball mill, stop the ball mill and check the meshing condition of the large and small gears. When everything is normal, open the manhole cover of the ball mill and add the remaining 20% steel balls for the second time.

Reasonable milling balls evaluation

Speaking from experience, after using the ball mill for a time, if the ball needs to be filled or replaced, the following two points can be used to determine whether the balls loading amount is reasonable.

1. Under the premise that the classifier overflow fineness and the ball mill’s ore supply amount are unchanged, the amount of sand returned is reduced, which indicates that the grinding function has been strengthened and the ball filling amount is suitable. At this time, the ball amount can be appropriately increased to increase grinding efficiency.

2. Observation of the sand return result of the classifier. If the particle size of the material close to the overflow is found to increase, it means that the ball mill steel ball proportion is insufficient, and the ball amount needs to be increased; otherwise, if the coarse particles increase in the return sand, it indicates that the number of big balls is relatively small, it should better add some big balls.

LATEST PRODUCTS

Twin Screw Feeder

【Feeding Capacity】 10-160 t/h【Power】 2.2-…

Tubular Screw Conveyor

【Capacity】6-50 m3/h【Procesible Material】 …

Heavy Plate Feeder

Capacity: 100-240 m3/h Power: 15-45 kW Speed: 0…