What is Tin ore?

Tin ore is one of the metals that mankind first discovered and used. In the early days, our ancestors used tin, copper and lead to produce bronzes. Tin and tin alloys have been widely used in modern national defense, modern industry, advanced science and technology and human life because of the ductility, stability of chemical properties, corrosion resistance and melting, small friction coefficient and non-toxic tin salt.

Tin ore has the characteristics of strong development, rust resistance and corrosion resistance. Tin can form various alloys with other metals and metals, and is easy to be plated on many metal surfaces. In particular, the surface of tin is corrosion-resistant and nontoxic.

Tin ore distribution in the world :

Tin ore deposits are relatively concentrated in the world, mainly in Southeast Asia, Central South America and eastern Russia, followed by eastern Africa, Western Europe and western North America. According to the “Minerals Commodity Summaries 2011” data issued by the US Geological Survey, the global identification of reserves is about 11 million tons, mainly in China, Indonesia, Peru, Brazil, Bolivia, Malaysia ,Nigeria, Myanmar, Australia, Mongolia, Kenya and other countries.

China is one of the countries with rich Tin Mineral Resources in the world. At present, China has found more than 520 tin deposits (including ore points and mineralized points). According to the mineral resources reserves Department of the Ministry of land and resources, the total reserves of tin in 2010 are 4 million 319 thousand tons of tin, which is the second place in the world.

Tin ore type existing in nature :

In the nature, the tin ore are existing in sand or alluvial raw material, this kind tin ore called sand tin or alluvial tin, the raw material may be with stone, sand, gravel, soil, sticky clay, some times with other magnetic iron, tungsten, ilmenite, hematite, monazite, zircon sand and other minerals. The sand/alluvial tin ore mine site is possible near river, on land , on mountain, or in the bushes, ect. The tin ore concentrate is visible by eye, usually size can be several mm or below 1 mm.

The other type tin ore is hard rock material, the tin is existing in hard rock, such as normal stone, quartz vein above the land. The rock tin ore is mostly like to be with tungsten ore together.

Tin ore as below pictures:

How to processing Tin ore?

In general, the tin ore processing machine of heavy selection are generally used, and the ore dressing of tin ore with high degree of dissociation of the monomer is basically the same as the ore dressing of gold ore, and the better ore dressing index can be obtained by simple screening.

For ore processing of tin ore with low dissociation degree, it is often necessary to break the secondary structure by bar grinding and other processes, so as to improve the recovery rate and concentrate grade.

The basis of the gravitational separation of sand tin ore processing machine is also the principle of gravity separation. According to the specific gravity difference between tin ore and waste stone, the proportion of the proportion of tin and waste stone in the tin deposit is very good, and the beneficiation effect can be obtained by the method and equipment of heavy separation in tin ore processing plant.

At the same time, the advanced tin ore processing plant has the advantages of high efficiency, energy saving, environmental protection and so on, the investment of equipment is small, and the operating cost is low. It is an ideal choice for the beneficiation of sands.

The equipment for gravity separation of sand tin ore is mainly jig. Sometimes, the rocking bed is also used to improve the recovery rate of fine grained tin ore. The technological process of gravity separation for sand tin ore is screening, jigging and dewatering. For the sand tin ore with a low degree of dissociation, two reelection processes are often needed: screen jig, rod mill, jigging and dewatering.

It is the most ideal, the most economical and the most effective tin ore dressing method at present, the most economical and the most effective method of tin ore dressing, small investment in the SN mineral reelection equipment, low operating cost and no pollution to the environment. The sieving heavy selection method is used in all big Sn washing plants and stannum staging ships to deal with tin ore, the effect of ore dressing is good and the application is very common.

JXSC mine machinery Company in China has more than 30 years professional experience at tin ore processing plant, design full set tin ore process flowchart , provide complete set tin ore processing plant, can send engineer to mine site for equipment installation and commissioning guidance. Have already built many tin ore processing plant in Africa countries. Include:China, Indonesia, Peru, Brazil, Bolivia, Malaysia ,Nigeria, Myanmar, Australia, Mongolia, Kenya ,ect.

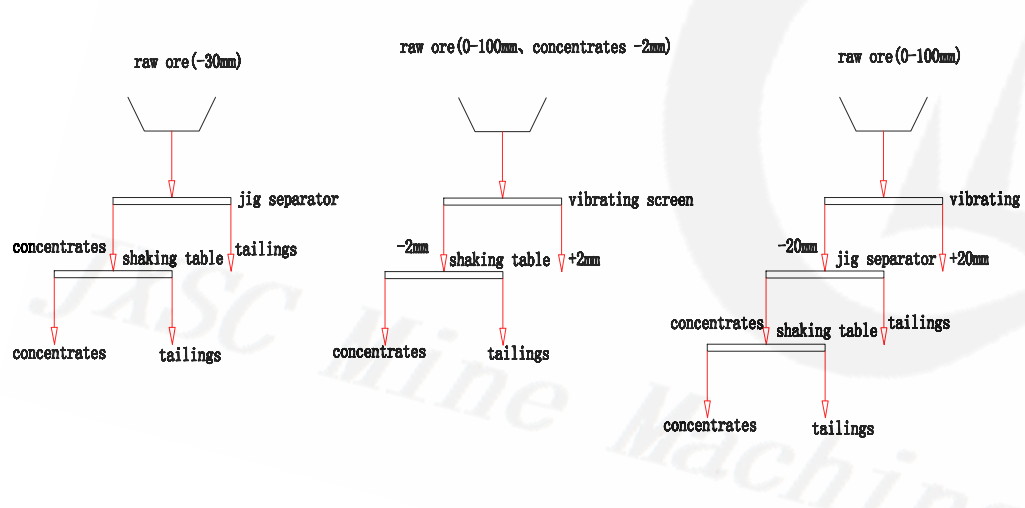

Below are the flowchart description that JXSC Engineer recommend for the tin ore processing plant:

Feeding->washing->sieving->primary separation -> final concentration

Tin ore Feeding: can be vibration feeding machine, feeding hopper, belt feeder, wheel loader or excavator feed directly. Usually will make grizzly bar on vibration feeder or hopper to remove big waste stones firstly. Depends on process capacity to choose which feeding machine.

Tin ore Washing: it is for washing clean the clay and mud in raw material, most popular used are tin ore washing trommel scrubber and tin ore washing trommel screen

trommel scrubber washing machine is for washing tin ore raw material that with many sticky clay, trommel screen is for wash tin ore raw material that without much sticky clay.

Tin ore Sieving: after washing, then sieve out some bigger waste stones ,the under screen slurry will go to next separation machine. This sieving process can use trommel screen or vibration screen or tin ore high frequency vibration screen.

Tin ore Primary concentration: it is for primary tin ore concentration process, jig separator is best choice. The concentrate ore discharged from them will send to final concentration machine.

Final Concentration: the concentrate ore from tin ore jig machine will go to tin ore shaking table concentration machine for final concentration, can get high grade tin ore concentrate

Tin ore Refining: if need much higher tin ore grade, can use magnetic separator to remove other magnetic minerals , such as iron, ilmenite, hematite, coltan, monazite,ect.

Rock type tin ore processing plant, the flowchart can be as below:

Feeding-> crushing->grinding->primary separation -> final concentration-> upgrading

The feeding way, primary separation, final concentration and tin ore refining process are almost the same as above alluvial/sand tin ore processing plant.

Below are the crushing and grinding stage description for rock tin ore processing plant:

Crushing: for crushing the big rock tin ore stone to smaller size before grinding.

crushers can be rough rock tin ore jaw crusher, rock tin fine jaw crusher, rock tin cone crusher, rock tin hammer crusher, roller crusher rock, depends on the rock tin ore feeding size and process capacity to use which kind crusher.

Grinding: after crush the stone to smaller size, need to grind to power by tin ore ball mill grinding machine or wet pan mill or other rock grinding machine, so the tin concentrate can released out from stone. Then go to gold separation machine and concentration machine.( tin ore shaking table)

Below Some pictures of tin ore processing plant in Uganda

LATEST PRODUCTS

Double Vibration Motor Feeder

【Capacity】30-300 t/h 【Feeding Size】0-550 mm …

Belt Feeder

【Capacity】 10-450 t/h 【Power】 1.5-2.5 kW/Mete…

Twin Screw Feeder

【Feeding Capacity】 10-160 t/h【Power】 2.2-…