NEW TYPE MINERAL PROCESSING DIAPHRAGM JIGGER

Diaphragm jig separator is a kind of popular gravity separation equipment, it can work great independently or work together with a shaking table. With the research and development of the jigging machine, the jig gravity separator has been very common and mode popular in these years.

JXSC mining machinery factory is a professional manufacturer of mining beneficiation equipment, has many clients with its rich chrome upgrading experience. We can do trial test for you if samples can be available.

Application of Jigger Machine

Saw-tooth Wave Jigger is capable of dealing with almost full sizes of mineral materials and very fine material. They can achieve a good result in processing such as placer gold, tantalum-niobium, titanium, tungsten, iron, tin, hematite, cope, manganese, barite, zirconium and chrome, etc. More and more prospectors prefer to use the Jigger Machine in Coal Mining, so It also plays a very important role in coal separation.

Jig machine is widely used in processing plant of tungsten, tin, gold, columbite, titanium, iron, coltan, manganese, diamond, chrome. It can also be used for recovery for alloy particles from manganese slag, chromites slag and stainless slag, etc.

To recover finished concentrate from ores in which the mineral grains are liberated. Recovery of minerals of various kinds that occur in Placer / alluvial deposits, or decomposed rocks.

Recovery of minerals from primary/ hard rock ore, which can be liberated by the crushing/ grinding process, i.e. (diamonds, color gemstones, barite, gold, other precious metals, base metals, ferrous metals, light metals, coal) and heavy minerals of all kind.

Cobbling operation, to discard waste rock before final processing of the crude concentrate.

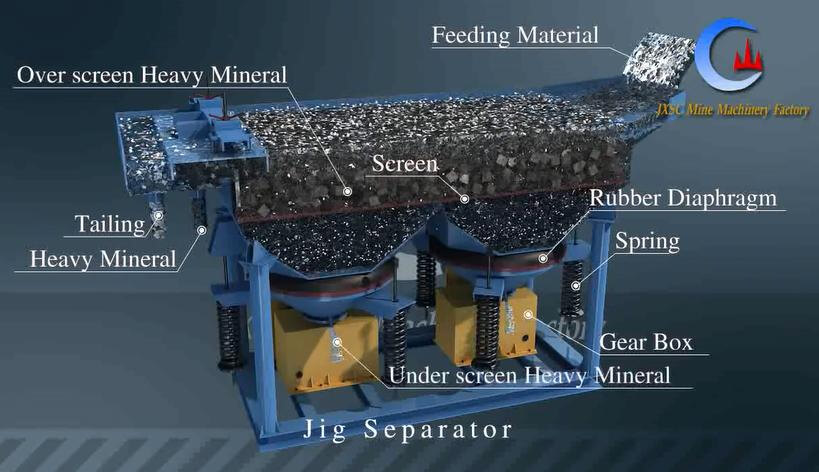

Description of diaphragm jigger

JT series jigger is a kind of new-type diaphragm jigger for ore beneficiation which is widely used in the ore beneficiation field. Its treatment capacity is large, and the feeding size range is wide. It can discharge both up and down. As the professional manufacturer of JT4-2 jigger, JXSC Mine Machinery Factory will introduce the characteristics and its usage.

JT4-2 jigger is first designed by the mineral institute to deal with iron ore. JXSC further improvement made it more adaptable and wider usage.

Advantages of diaphragm jigger

1) higher beneficiation efficiency than the former ones

2) the design is much more reasonable and the failure maintenance rate is lower.

3) large treatment capacity of 15t/h with large treatment size up to 30mm

4) up & down-discharging. -8mm discharged from lower discharging port and 8-30mm discharged from the upper discharging port

5) wider usage. This new-type JT4-2 can be widely used for the beneficiation of hematite, limonite, specularite, manganese, mercury, antimony, fluorite, barite, celestite, pyrite and so on.

6) JT4-2 jigger can beneficiate ore below 30mm avoiding the classifying.

JXSC Mine Machinery Factory, a professional manufacturer of mining beneficiation equipment, has the impeccable trial platform which can do a free machine test. And we can design the flow sheet for your ore beneficiation.

Specification

| Model | Area jig | Stroke | Stroke | Feed size | Hutch water | Pressure water | Capacity | Power | Overall dimensions | Weight |

| m² | mm | r/min | mm | t/h | kg | t/h | kw | mm | t | |

| JT0.57-1 | 0.57 | 8.5-12 (M12)10-17 (M17) | 60-160 | < 6 | 1-2 | ≥ 0.3 | 1-2.5 | 1.5 | 1560× 820× 1550 | 0.612 |

| JT1-1 | 1.04 | < 10 | 2-3 | 4-10 | 2.2 | 1322× 1190× 1915 | 0.9 | |||

| JT2-2 | 2.28 | 8.5-12 (M12)10-17 (M17) | 60-160 | < 10 | 2-4 | ≥ 0.3 | 8-15 | 3 | 3225× 1550 × 2150 | 1.637 |

| JT3-1 | 3.3 | 10-47 | 80-110 | < 20 | 3-6 | ≥ 0.1 | 10-15 | 5.5 | 2662× 2000× 3030 | 3.26 |

| JT4-2 | 4 | 7-30 | 50-125 | < 10 | 4-8 | ≥ 0.1 | 8-16 | 7.5 | 4240× 1990× 5750 | 4.6 |

| JT4-2A | 4 | 7-30 | 50-125 | < 10 | 4-8 | ≥ 0.1 | 8-16 | 4 | 4240× 1990× 2750 | 4.6 |

| JT5-2 | 4.86 | 15-25 | 80-120 | < 10 | 4-10 | ≥ 0.1 | 10-20 | 7.5 | 3940× 2006× 2580 | 4.8 |

The advantage of JXSC mineral jig separator

1. High capacity

2. High concentration ratio and high recovery

3. Fabricated with highest quality material

4. Easy to install, operate and maintain

5. The pulsation curve is saw-tooth wave shape facilitate heavy mineral to settling

6. Saving water 30-40% than an ordinary jig

7. The pulsation speed very easy adjusted by the regulator

8. Suitable for roughing and desliming

9. Can achieve a good result in processing such as placer gold, tungsten, iron, tin, hematite, cope, tantalum-niobium, titanium, manganese, barite, zirconium, chrome and gemstone, etc.

Diaphragm jigger is mainly jigging gravity separation with its simple operation, high recovery, and good separation efficiency. The water in jig gravity separation can be recycled and it is friendly to the environment. The jigger for diamond mining separation needs no classification with its four independent slots and eight jigging boxes. This jigger is the jig machine with the longest jogging distance and best recovery, and also it is adaptable for kinds of ore beneficiation and smelting alloy recovery. The picture of jigger and its details are as below: