Grinding process is a subsequent step after the ore crushing process, and be an important part of the preparation work before mineral sorting. The ore grinding machine is usually working with the classifier.

The grinding mills grind the feed material to a smaller size, and the classifier divides the ground products into qualified and unqualified products. In which, the unqualified material is returned to grinder mill for re-grinding.

The classification process includes pre-classification, checking classification, and controlling classification.

Related products: crushing and grinding machine, rod mill, ball mill, feeder & conveyor belt, particle classifier.

How to determine the grinding circuit layout?

The main factors affecting the determination of the number of grinding sections are: ore grindability, mineral characteristics, feed size, required grinding size, production scale, etc.

The result shows that, for ore beneficiation processing, one or two stages of grinding can achieve the target particle size required for beneficiation, multi-stages usually determined by the high precision requirement and multi-phase separation.

What is one stage & two stages grinding circuit?

1 One stage grinding circuits

Compared with the two-stage grinding process, the main advantages of a stage grinding process are less equipment, low investment, simple operation, short downtime. However, the one-stage grinding mill has a wider range of grain size, which is difficult to obtain a fine final product.

When to adopt one-stage grinding?

The maximum particle size of final product is 0.2 ~ 0.15mm ( -200 mesh 60% to 79%);

Small processing plant, to simplify the equipment configuration and to save cost, its required fineness is -200mesh 80%.

Layout and configuration

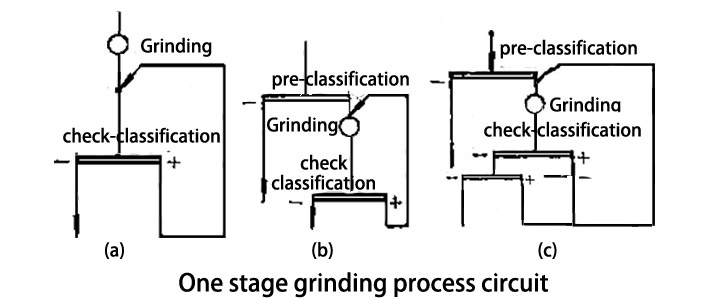

Generally, grinding machine working with the classifier, three common one stage grinding process circuit as following.

One stage grading process with checking grading operation is the most widely used. The ore is directly fed into the grinding machine, and the optimum particle size for the ore is generally 6-20 mm. Particle checking classifier separates the ground material into qualified products and unqualified products, the unqualified materials are sent back to grinding mill.

When the ore contains a large amount of fine qualified ore, and it is necessary to pre-separate the soluble salts contained in the raw ore, the one-stage grinding process with pre-grading and checking classification should be employed.

The purpose of pre-separation is to remove the qualified fine size ore, thereby increasing the efficiency of the grinder, and also separating the ore slime for convenient subsequent processing.

Pre-grading is generally performed by mechanical means. In order to prevent serious mechanical wear, the grain size of the ore should not exceed 6 ~ 7 mm, and the qualified grain size should not be less than 14 ~ 15%.

One stage grinding with controlling grade process can obtain the fine size product. compared with the two-stage grinding process, the great feature is that the one-stage process needs only one grinding machine, that is suited for small processing plants.

2 Two-stage grinding circuits

The outstanding advantage of the two-stage grinding process is that coarse grinding and fine grinding can be carried out separately in different grinding sections. Coarse grinding, loading of larger steel balls and higher speed, which is beneficial to improve grinding efficiency; when fine grinding, loading of smaller steel and lower speed also improve the grinding efficiency.

Another great advantage of the two-stage grinding process is that it is suitable for stage sorting separation. When dealing with unevenly embedded ore and ore containing large specific gravity minerals, the sorting operation can be used in the grinding cycle to sort out the separated minerals in time to prevent over-grinding and improve the quality of mineral; at the same time, it can reduce the accumulation of heavy metal minerals in the graded return sand, and can improve the classification efficiency of the classifier.

When to adopt two stages grinding?

For medium and large scale mineral processing plants, two stages grinding to be economical when grinding fineness is less than 0.15mm.

Layout and configuration

Generally, adopt a two-stage grinding process to obtain finer grinding products, and separate mineral particles more accurately. The primary classifier in the first stage to select the ore concentrate, the rest of the ground product, namely middling and tailings, then enter the secondary grinding mill.

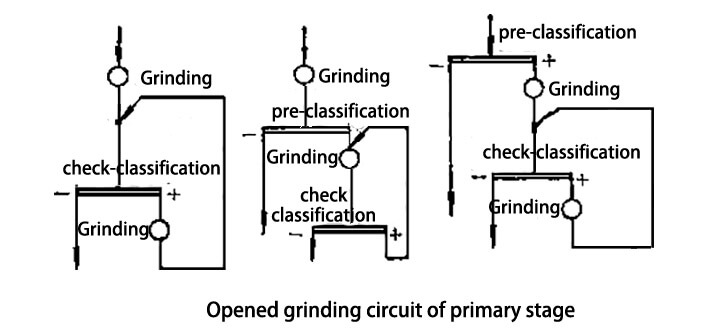

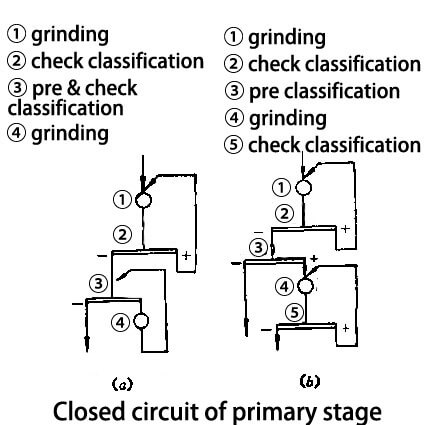

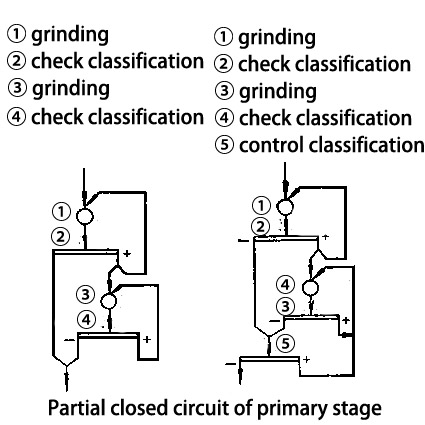

According to the different layout of the primary grinder and classifier, the two-stage grinding process can be divided into three modes, opened grinding circuit of primary stage, closed-circuit of primary stage, and partially closed circuit of the primary stage.

(1) Opened grinding circuit of the primary stage

There are three common designs of opened grinding circuits of primary stage, usually used in large scale mining plants.

(2) Closed-circuit of the primary stage

Usually used to process fine hard ore, especially suited for large scale plant that requires a grinding fineness of less than 0.15mm.

Properly arrange loads of the first and second stages of the mill is important to maximize the processing efficiency. The reasonable distribution of the load between the two grinding sections can be achieved by controlling the overflow particle size of the first stage classifier.

(3) Partially closed circuit of the primary stage

Advantages: no need for thinking about the load distribution of each grinding stage; avoid the gathering of precious metals in the grinding cycle.

JXSC, 35 years of experience in crushing machine design and manufacturing, always focuses on the mineral processing industry, brings reliable and safety mining equipment and effective solutions for every customer.

LATEST PRODUCTS

Twin Screw Feeder

【Feeding Capacity】 10-160 t/h【Power】 2.2-…

Tubular Screw Conveyor

【Capacity】6-50 m3/h【Procesible Material】 …

Heavy Plate Feeder

Capacity: 100-240 m3/h Power: 15-45 kW Speed: 0…