Ore screening is to screen and separate the material with a particle size below 250 um, among which the classification of materials below 10 um is called superfine classification. Ore classification affects the crushing and grinding process and controls the particle size of the final product, which in particular plays an important role in product quality.

Ore screening is divided into the wet type and dry type screening, the former refers to the material in a liquid medium (generally water), and the latter refers to the classification processed in a gaseous medium (generally air).

Dry-type grading is the only option in areas where water is scarce and dry, and where water is not allowed in the process. Besides, in the cold regions, the application of dry grading is not affected. The dry screening method saves a lot of water, and also eliminates the problem of wet grading and subsequent dewatering, and is an effective energy-saving grading method.

Join us to know the main dry-type ore material screening principle.

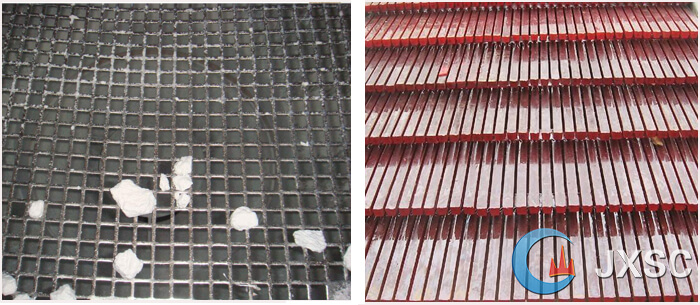

Grading by particle size is mainly for fine particle, which is an accurate grading method. There are two ways to control the particle size: sieve mesh pore and screen seam. The screen mesh sizes can control the two-dimensional size of the particles, and the sieve seam can only control the one-dimensional size of the particles, so the mesh control granularity is more precise.

In order to prevent clogging, the fine material is mostly used sieve seam/ sieve strip rather than mesh pore type, and the fine screen often works in a high-frequency vibration mode.

The gravity settlement classification is realized by the different settlement velocity of the material particles in the fluid medium.

In a fluid that rises at a certain speed, the sedimentation velocity of the coarser particle is higher than the fluid ascending velocity, and thus moves downward; the finer particle sedimentation velocity is lower than the fluid ascending velocity, and thus is driven upward by the fluid, thereby achieving classification.

The density of the particles has an effect on the settling velocity and therefore has a certain influence on the classification process. The density of the gas is lower than that of the liquid, so dry gravity settling is suitable for fine-grained classification than wet gravity settling.

When the direction of fluid movement changes, the particles of the material moving with the fluid deviate from the direction of fluid motion under the control of inertia. The larger the particle size, the greater the degree of deviation, whereby particles of different particle sizes are classified. In order to avoid the movement of the particles with the fluid, the friction between the fluid and the material particles is required to be as small as possible, and the dry classification is more suitable for adopting this principle.

In the gravity field, the classification of the material particles is limited by the gravitational acceleration, the classification process is slow, the efficiency is low, and the centrifugal movement can greatly improve the classification speed and efficiency.

In recent years, the ultrafine grading technology has been continuously developed, the most prominent ones are rapid grading, decompression grading and high-voltage electrostatic grading.

In the dry grading process, the slower the particle moving speed is closer to the grading point size (the slower the particle sedimentation is thicker than the kerf particle size, the slower the particle size is finer than the kerf size), and thus the retention in the grading zone The longer the time. This caused the accumulation and agglomeration of this part of the particles, which interfered with the classification process. Therefore, the grading process should be completed as quickly as possible, which is a rapid grading. The rapid grading measures are highly accurate and highly accurate micro-feeds before grading.

In air-mediated dry grading, the greater the air pressure in the grading zone, the slower the sedimentation velocity of the granules and the larger the grading of the grading cut points. Therefore, in order to obtain a finer kerf size, the air pressure should be reduced, that is, the pressure grading. The difficulty in achieving this principle is that the lower the air pressure, the worse the classification accuracy is, and the wider the particle size range of the product.

The high-voltage electrostatic classification principle is that the ultra-fine powder particles are charged and dispersed, and are subjected to electrostatic force and gravity in the electrostatic field and the gravity field. The particles of different particle sizes have different effects due to the combined force of electrostatic force and gravity. Motion trajectory to achieve grading.

Ore screening affects the crushing and grinding process and controls the particle size of the final product, which in particular plays an important role in product quality.

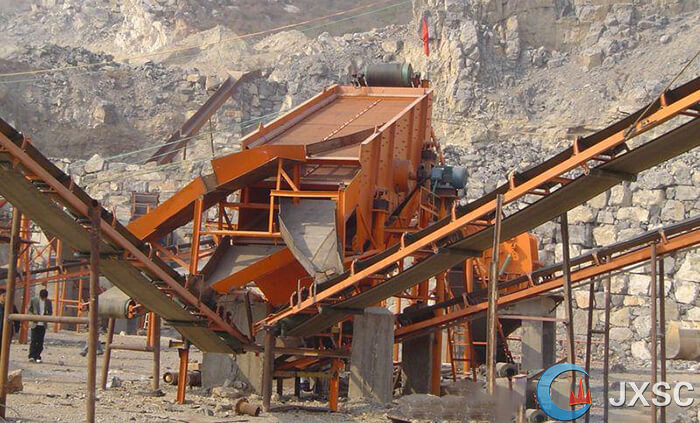

JXSC, 35 years of mining equipment manufacturing, provides different types of ore screening machines include the wet type and dry type.

Spiral classifier, vibrating screen, hydraulic classifier, etc.