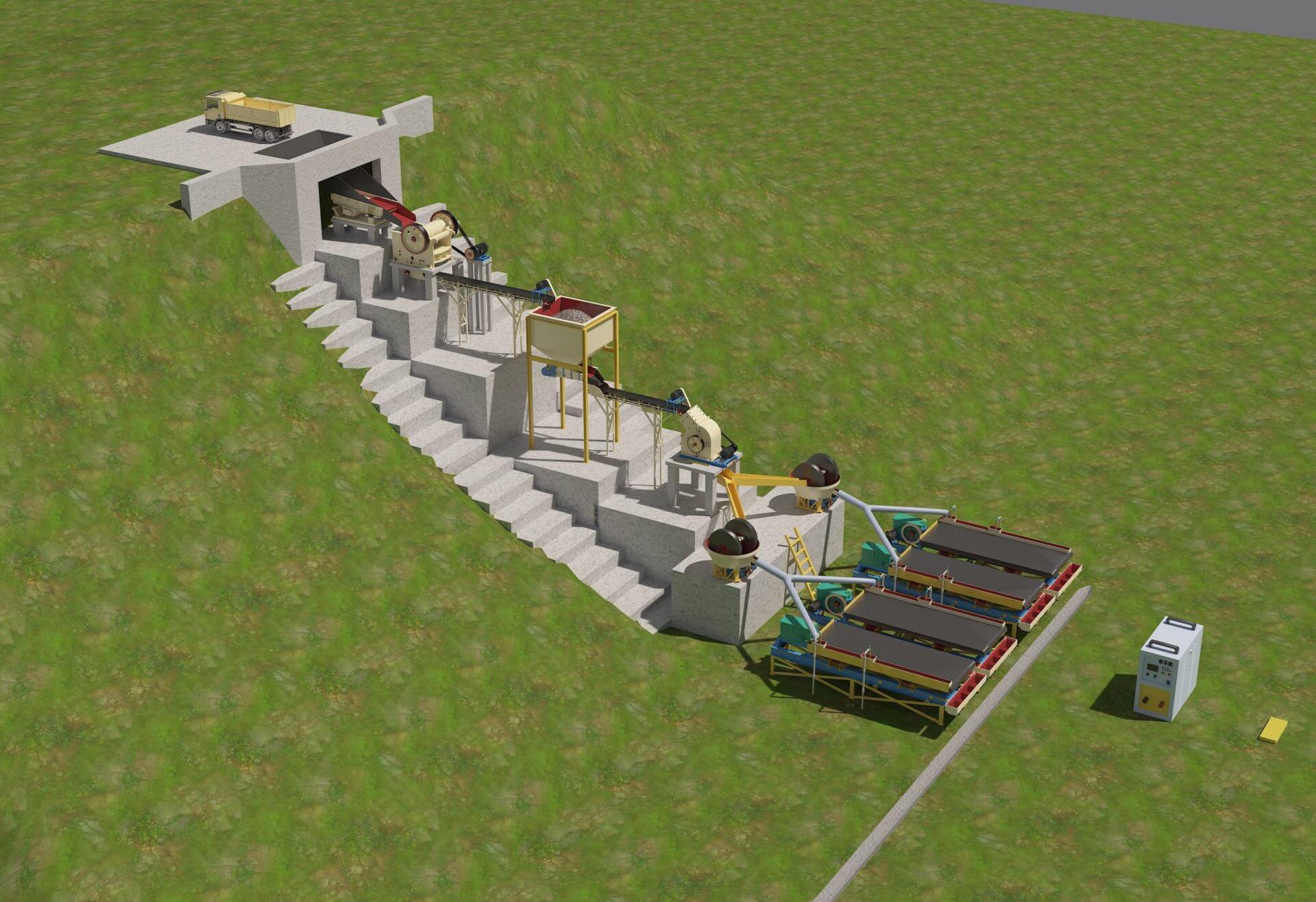

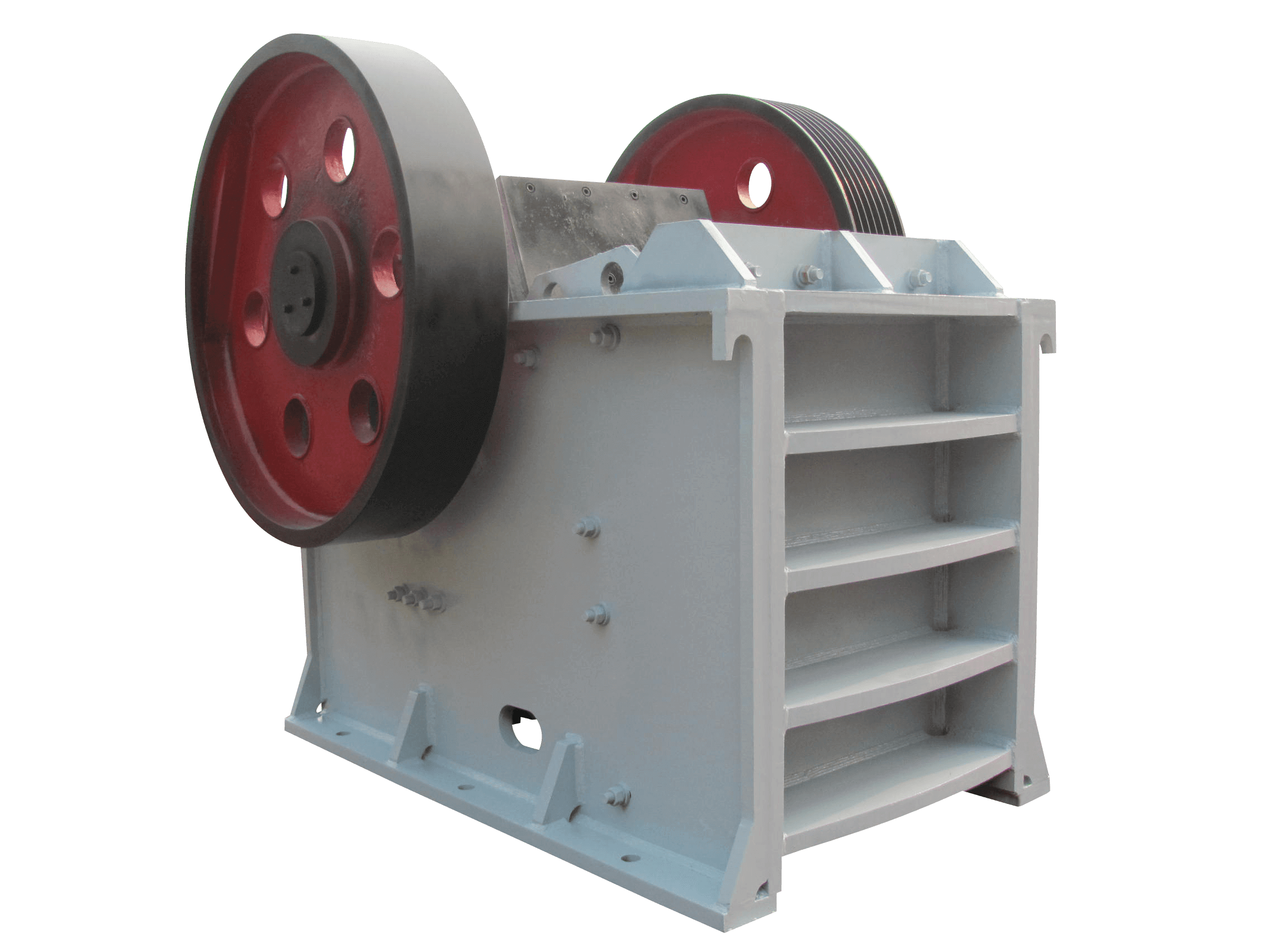

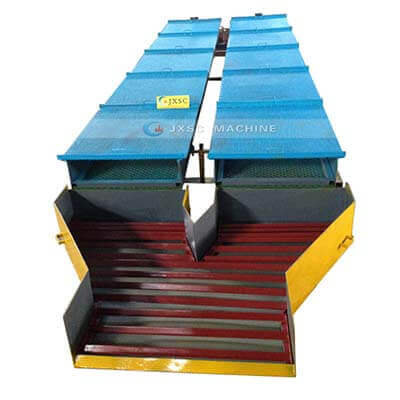

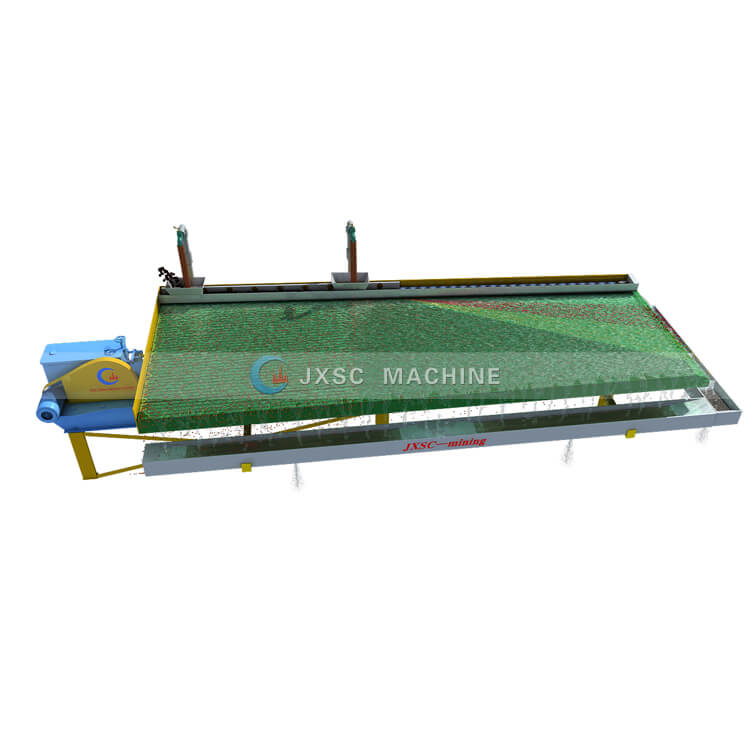

There are some popular economic gold mining solutions in Africa, the mining equipment it often uses is a wet pan mill, impact crusher, shaking table, etc., They are all economical and welcome by African people.

JXSC is a professional mining equipment manufacturer and has rich experience in gold mining solutions flow design. Here are some economical gold mining plants to introduce to you.