The main component of pyrite is FeS2, the primary raw material for making sulfuric acid. Due to its enormous specific gravity, it is often used as a filler. The particular gravity of pyrite is 4.9-5.2, and its beneficiation method is mainly gravity separation. Pyrite has an enormous specific gravity and coarse particle size, and the associated gangue generally has a small specific gravity. Therefore, gravity separation using the specific gravity difference between pyrite and waste rock can obtain ideal mineral processing indicators. The gravity separation process is also commonly used in pyrite mineral processing technology. Flotation technology can also be used to benefit low-grade, fine-grained drastic ores. Still, the investment in flotation technology equipment is large, the operating cost is high, and it also causes particular pollution to the environment.

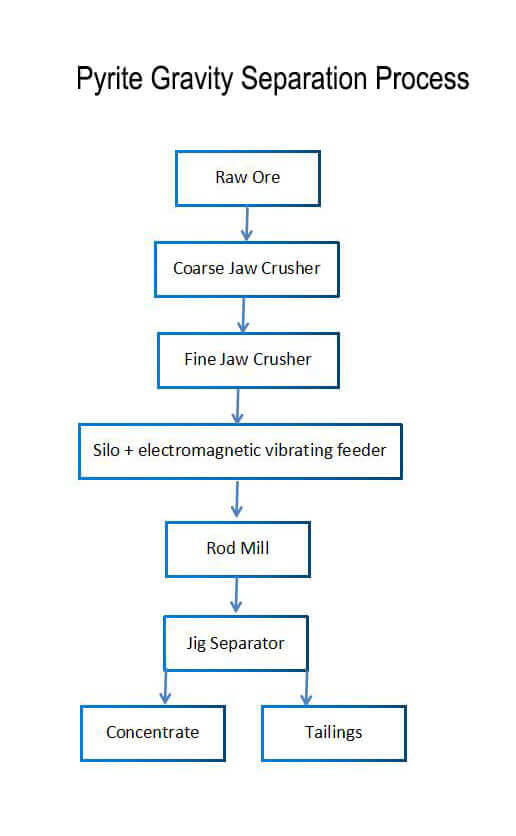

Pyrite Gravity Separation Process

The embedded particle size of pyrite is generally coarse, especially for coal-based pyrite and Ma’anshan coarse-grained pyrite. First, the raw ore is crushed to the extent that pyrite and waste rock are separated, and then it enters the jig for sorting. We can obtain good mineral processing indicators in one sorting, and the concentrate grade and recovery rate are both satisfactory.

The pyrite gravity separation process has the advantages of energy saving, high efficiency, environmental protection, small equipment investment, and low operating costs. It has become one of the essential methods of pyrite beneficiation and is widely used in new pyrite beneficiation plants. The mineral processing equipment is mainly a jig; sometimes, a shaker is used.

The pyrite gravity separation process schematic diagram

Introduction to the pyrite gravity separation process

The raw pyrite ore is crushed by the jaw crusher to the optimal particle size for the rod mill and then transported to the rod mill for grinding via a belt conveyor to dissociate the pyrite and waste rock monomers. The grinding products directly enter the jig. The machine performs gravity separation, and concentrates and tailings are obtained in one separation.

The purpose of using a rod mill for grinding in this process is that the discharging particle size of the rod mill is uniform and adjustable, and the processing capacity is large. The pyrite is not easily over-crushed during the grinding process, which benefits the gravity separation process’s separation effect and efficiency.

According to the particle size of the pyrite, we use the corresponding jig. We use a fine-grain gravity separation sawtooth wave jig if the particle size is fine. And we use an ordinary sine wave jig if the particle size is coarse.

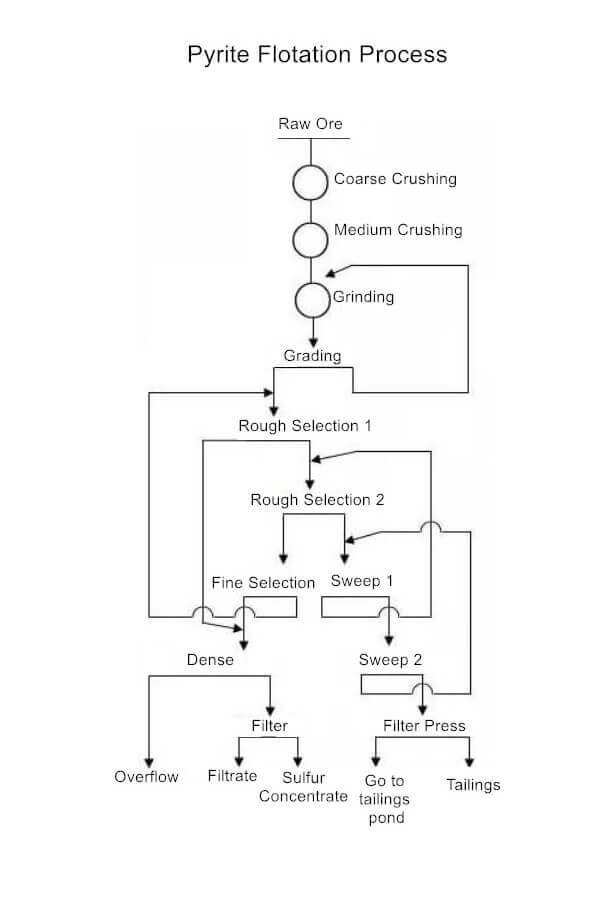

Pyrite Flotation Process

The flotation process can benefit low-grade pyrite with finer particle size. Pyrite is an easy-to-float mineral. The flotation operation can be completed using a simple process, and the beneficiation index is high.

The flotation process equipment requires a large investment, high operating costs, and certain pollution to the environment. Its use is restricted in some areas. Flotation equipment includes crushers, ball mills, classifiers, flotation machines, etc.

Pyrite flotation process schematic diagram

Introduction to the pyrite flotation process

- Crushing Process

The crushing process adopts two-stage open-circuit crushing, and the raw ore is crushed to less than 30mm through two jaw crushers. - Grinding and grading process

The grinding process uses a ball mill to grind the ore; the grinding fineness is -200 mesh, accounting for 72%, and the graded overflow concentration is about 33%. - Flotation process

The flotation process adopts one rough separation, one selection, and two sweeps to ensure the concentrate grade while improving the comprehensive recovery rate of pyrite flotation. - Dehydration process

The dehydration process uses a concentrator to concentrate and a vacuum filter to filter.

This pyrite flotation process is suitable for beneficiating low-grade fine-grained disseminated pyrite. A specific pyrite mine adopts the above process, with a raw ore grade of 12%, a concentrate grade of 41%, and a comprehensive recovery rate of 96%. It is an ideal process flow for pyrite flotation. The flotation reagents are 400 g/ton of ethyl xanthate as collector and 108 g/ton of pine alcohol oil as foaming agent.

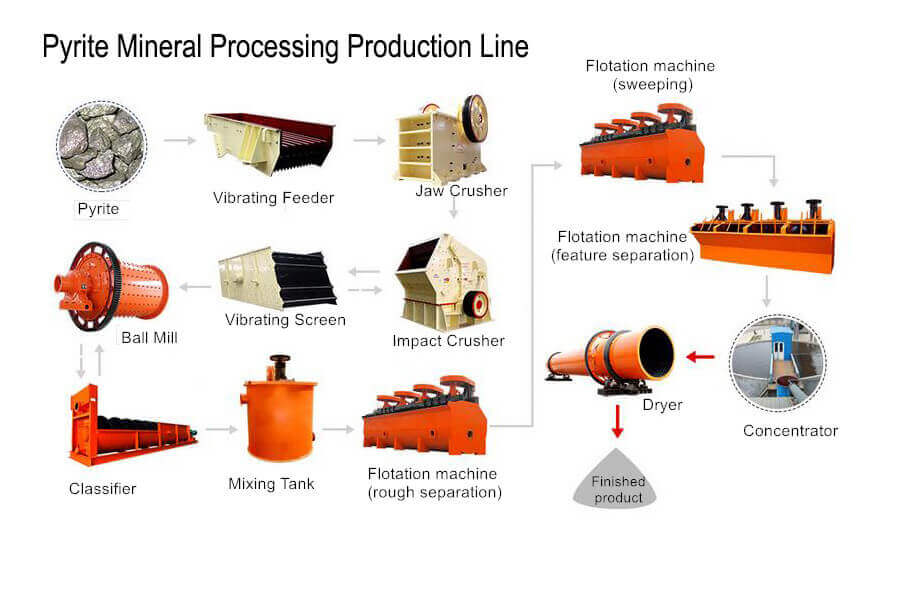

Pyrite Mineral Processing Production Line

The jaw crusher first crushes the mined pyrite ore, and the ore enters the impact crusher for secondary crushing. After being crushed to a reasonable fineness, it is evenly sent to the ball mill through the elevator and feeder, and the ball mill crushes the ore. Crush and grind. The fine pyrite ore ground by the ball mill enters the next process – classification. The spiral classifier uses the principle that the specific gravity of solid particles is different and the speed of precipitation in the liquid is different to clean and classify the pyrite mixture.

The washed and classified mineral mixture is sent to the flotation machine, and different drugs are added according to different pyrite mineral characteristics to separate the desired pyrite minerals from other substances. After the desired minerals are separated, because they contain a large amount of water, they must be initially concentrated by a concentrator and then dried by a dryer to obtain dry minerals.

Production line advantages

- The pyrite beneficiation production line has high beneficiation indicators for processing pyrite, but the equipment investment is enormous, and the production cost is low. It is a low-investment and high-return project.

- The overall operation is smooth during use, without large-scale starting or failure. In particular, the flotation machine has a large air suction capacity and low environmental pollution, and wear-resistant parts protect all accessories.

LATEST PRODUCTS

Twin Screw Feeder

【Feeding Capacity】 10-160 t/h【Power】 2.2-…

Tubular Screw Conveyor

【Capacity】6-50 m3/h【Procesible Material】 …

Heavy Plate Feeder

Capacity: 100-240 m3/h Power: 15-45 kW Speed: 0…