What is Chrome ore?

Chromite is an oxide mineral of chromium and iron. It has high carbon ferrochrome, medium carbon ferrochrome, low carbon ferrochrome, micro carbon ferrochrome, metal chromium, and silicon chromium alloy. It’s quite hard, black and semi metallic.

Chromite is the main source of metal chromium and can also be used for refractory materials at high temperature. Chromite is generally lumped or granular. It has a normal spinel structure. Chromite Cr2O3 content of 67.91%, is the main source of industrial chromium, also can produce high-temperature refractory, with weak magnetism. Large chromite deposits are mainly found in South Africa, Zimbabwe, Russia and Cuba.

Chrome ore distribution in the world :

Chrome ore is widely distributed in South Africa, Zimbabwe, Madagascar, Belgium, Sudan, Albania, Turkey, Iran, India, the Philippines, kazakhstan, Finland, Russia.

South Africa’s Chromite inventories rank first, and chrome ore reserves are as high as 72%. However, the amount of chrome ore exported to China from Zimbabwe and Kazakhstan, which has fairly high reserves, is not large. Turkey, with a reserve of only 0.9%, has become the second largest importer of chromite in China. Of course, such as Finland and India, although the export volume is small, but its own ferrochrome smelting technology is also high, ferrochrome quality is better.

Chrome ore Applications:

Metal chromium is mainly used to smelt special alloys with cobalt, nickel and tungsten. These special and special alloys are indispensable materials for the production of guns, missiles, rockets and ships in the aviation, aerospace, automobile, shipbuilding, and national defense industries.

On refractories, chromite is used to make chrome bricks, chrome magnesite bricks and other special refractory materials.

In chemical industry, chromite is mainly used to produce sodium dichromate, and then other chromium compounds, used in pigments, textile, electroplating, leather and other industries, as well as catalysts and catalyst agents.

Chrome ore type existing in nature :

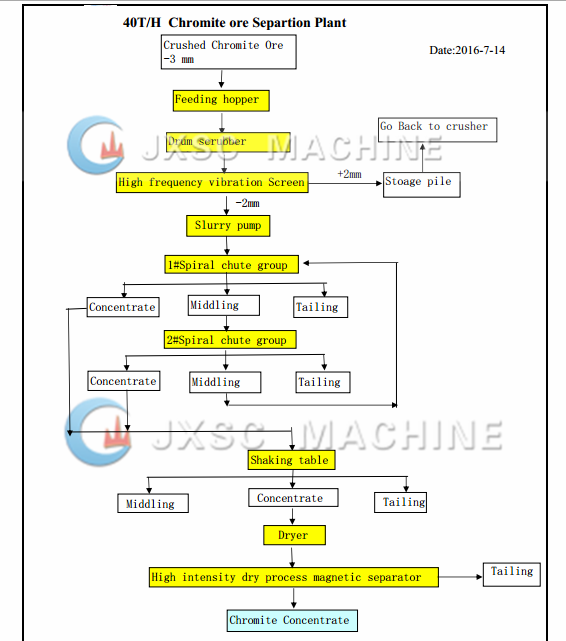

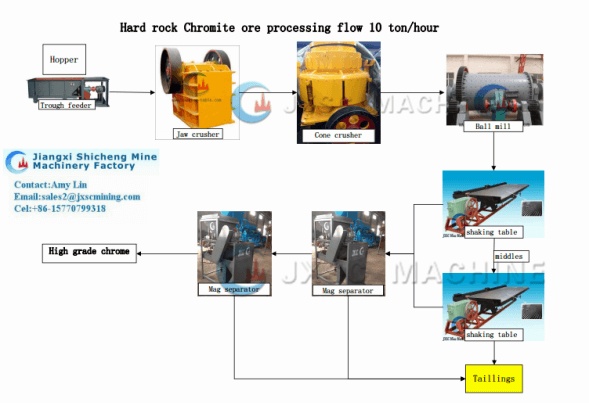

In the nature, the chrome ore are existing in sand or alluvial raw material, this kind tin ore called sand chrome ore or alluvial chrome ore, the raw material may be with stone, sand, gravel, soil, sticky clay, some times with other magnetic iron, ilmenite, hematite and other minerals. The sand/alluvial chrome ore mine site is possible near river, on land , on mountain, or in the bushes, ect. The chrome ore concentrate is visible by eye, usually size can be several mm or below 1 mm.

The other type chrome ore is hard rock material, the chrome ore is existing in hard rock, such as normal stone, quartz vein above the land. The rock chrome ore is mostly like to be with iron together.

Chrome ore as below pictures: