In the process of sand and gravel production, do you often encounter the problem of excessive soil content in raw materials? Or is the content of sand, stone and silt produced too high? Excessive soil content will have a serious impact on the quality of finished products. How to solve it? Today, we will introduce the method of earth rock separation and what kind of equipment is used for earth rock separation.

How to separate earth and rock?

Refer to soil rock separation, it has a key impact on the quality of sand and stone. We need to take corresponding treatment measures according to the soil content in sand and stone in time. Stone and soil are generally separated by earth rock separator, that is, the two are separated by screening through earth rock separator, also known as screening machine.

Generally, the screening machine works together with other crushing equipment. It can not only separate earth and rock, but also separate stones, sand and gravel. Generally, it can be placed at the end of the production line or pre screened before crushing, so that the quality of aggregate and sand produced by the production line will be better.

What kind of equipment is good for earth rock separation?

There are two types of machines that separate stone and soil. One is fixed earth rock separator and the other is mobile earth rock separator. Due to different names in different places, this machine that separates stone and soil is also called screening machine, what is also called vibrating screen we often say. It generally works in combination with other crushing equipment. This earth rock separator is required for crushing stones into stones or into sand. It is generally placed at the end of the production line process. There are also special earth rock separators in the middle of the crushing equipment, so that the quality of aggregate will be higher.

Fixed earth rock separator: as the name suggests, its working mode is fixed. It needs capital construction, piling and installation before it can be put into production. It can be installed on a firm reinforced concrete base or steel frame, and the installation angle is generally 20 °.

Mobile earth rock separator: compared with fixed, this equipment realizes the function of mobility. It is equipped with mobile frame with crusher and feeder, which can directly go deep into the site and be put into production immediately. The mobile machine is a movable screening equipment, with crawler and tire as the frame. It can be equipped with different types of vibrating screens, crushing and sand making equipment. One machine is comparable to a production line; It can also remotely control the operation, reducing the investment of human and material resources; The hydraulic lifting design is adopted, and the whole machine can realize folding, expansion and telescopic operation, saving floor space during shutdown.

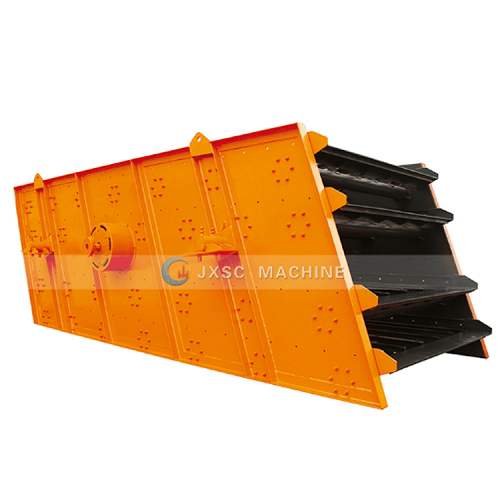

We know earth rock separator is a screening machine. Vibrating screen uses vibrator to excite the screen to produce reciprocating vibration to screen earth and rock. In the sand and gravel production line, the vibrating screen can pre screen the materials, check and screen the crushed materials, and screen the particle size of the finished products. In the screening machine, we commonly use the circular vibrating screen.

As a common earth rock separation equipment, circular vibrating screen has the characteristics of multi-layer number, high efficiency and high frequency. Circular vibrating screen is a circular track movement of materials in the screening process. It can screen the materials with particle size not exceeding 400mm, and the output is about 10-1000 tons. It can be used in coal preparation, metallurgy, building materials, mining and other industries. In addition, there are many types of circular vibrating screen, which can be configured according to the production requirements of the branch.

Operating Principle of Circular Vibrating Screen

The vibrating screen is mainly composed of screen box, vibration exciter, suspension device and motor. The motor drives the main shaft of the vibration exciter to rotate through the triangular belt. The screen box vibrates due to the centrifugal inertia force of the unbalanced weight on the vibration exciter. Different amplitudes can be obtained by changing the eccentric shaft of the exciter. In addition, there are 2, 3 and 4 layers of screen of earth rock separator. The number of layers, amplitude and inclination jointly affect the specification, quantity and output of finished products.

How to Choose Circuit Vibrating Screen?

- Materials

When choosing a circular vibrating screen equipment, the first thing to consider is the type of material. In production, there are many and varied materials, and their hardness and properties are quite different. Common materials such as ore, sand and powder. When users choose circular vibrating screen equipment, they must make a reasonable choice according to the actual production situation, combined with factors such as the structure, water content, and characteristics of the material, so as to give full play to the advantages of the vibrating screen.

- Actual Production Needs

The function of the vibrating screen is to remove the impurities contained in the materials, improve the quality of the materials, and screen out qualified materials for further processing and use. Therefore, when users choose circular vibrating screen equipment, they must conduct a comprehensive analysis based on their own production needs, screening grades, screening requirements, filtration levels, etc., and communicate with the merchants in time to select the appropriate circular vibrating screen equipment.

- Production Output Size

For users, when choosing a circular vibrating screen, the production capacity of the production line must also be considered. There are many types of vibrating screens, and the production capacity of different types of vibrating screens is also quite different. Therefore, before choosing a circular vibrating screen, the user must understand the production capacity of the production line before purchasing. Pay attention to the sieving accuracy and screen specifications of the vibrating screen when purchasing.

As a commonly used production equipment, circular vibrating screen has greatly promoted the production of sand washing, sand making, and mining. For users, it is very important to purchase vibrating screen equipment that meets their own production needs. Therefore, when users choose circular vibrating screens, they should combine the actual situation and make more comparisons.

LATEST PRODUCTS

Twin Screw Feeder

【Feeding Capacity】 10-160 t/h【Power】 2.2-…

Tubular Screw Conveyor

【Capacity】6-50 m3/h【Procesible Material】 …

Heavy Plate Feeder

Capacity: 100-240 m3/h Power: 15-45 kW Speed: 0…