Mine tailings refer to the waste or by-products produced during mining in mines. When the valuable minerals in an ore are extracted, the remainder usually consists of finely powdered rock particles, water, and other residual materials. These residues are called tailings, also known as ore waste, ore tailings, or tailings slag.

The composition of tailings depends on the methods used in the mining process and the type of ore being mined. Tailings may contain untreated ore, chemicals, water, and other solid waste. These wastes are usually stored as a slurry in tailings ponds or dams.

Tailings are often considered one of the environmental challenges in mining activities because they may contain chemicals that are harmful to the environment. Sometimes, tailings can lead to water pollution, land degradation, and ecosystem damage.

Tailings Recycling

Tailings recycling refers to recovering valuable materials from mine tailings, which are the by-products generated during the extraction of minerals from ore. Instead of allowing these tailings to be disposed of as waste, recycling involves reprocessing them to extract any remaining valuable minerals. The goal is to reduce environmental impact, optimize resource utilization, and potentially extend the economic life of mining operations.

Necessity of Tailings Recycling

The necessity of tailings reprocessing is mainly reflected in several aspects:

- Resource Recovery: Tailings may contain valuable minerals that were not fully extracted, such as gold, silver, copper, etc. Through reprocessing, these valuable minerals can be further extracted, maximizing the utilization of resources in the ore and enhancing the economic benefits of mining activities.

- Environmental Protection: Untreated tailings may contain harmful chemicals, leading to water pollution and ecosystem damage. Reprocessing reduces the release of hazardous substances, minimizes environmental impact, and aligns with sustainable mining practices.

- Improved Tailings Dam Stability: As reprocessing may reduce the volume and weight of tailings by extracting valuable minerals, it can alleviate pressure on tailings dams, contributing to their stability. It is crucial for preventing disasters such as tailings dam failures.

- Extended Mine Life: Reprocessing enables more efficient resource utilization, thereby extending the lifespan of the mine. It is strategically significant for supporting long-term sustainable mining operations.

- Compliance with Regulations and Social Expectations: Mining companies must adhere to strict environmental regulations and social responsibility standards in many countries and regions. Tailings reprocessing helps companies meet these regulations and societal expectations, reducing negative impacts on surrounding communities and the environment.

In summary, tailings reprocessing facilitates maximization of resource utilization, reduces environmental impact, and promotes sustainability in mining activities. However, carefully considering the balance between technological feasibility, economic costs, and environmental benefits is necessary when implementing these reprocessing processes.

Overall Utilization of Tailings Resources

(1) Used as building materials

- Making sand and bricks for construction and paving gravel for roads and railways.

Research has found that iron tailings from a certain mine can partially replace ordinary clay to develop building bricks. The sintering Bricks are much stronger and harder than ordinary clay bricks, are cheap to make and process, and have broad application prospects. - As a raw material for preparing ceramics, etc.

After further processing, the tailings from a particular processing plant can be used to make composite materials, crystallized glass, lightweight materials, optical products, etc. Moreover, after secondary recycling, the tailings can be used as raw materials for ceramics, cement, etc., based on their physical and chemical properties.

(2) Used as mineral fertilizer or soil conditioner

Some mine tailings contain iron, phosphorus, zinc, molybdenum, vanadium, boron, copper, and other elements. Appropriate amounts of these elements can maintain the normal growth and development of plants. Mineral tailings from some mines can be properly processed to produce mineral fertilizers, improving soil quality. It not only improved the magnetism of the soil but also changed the structure of the magnetic particles in the soil, ultimately reducing the soil’s air permeability and porosity. , the structure has been improved.

(3) Backfilling mine goaf areas

The development of mineral resources has formed large areas of mined-out areas, and surface subsidence and surface water leakage have greatly harmed human survival. A concrete slurry pump is used to transport the slurry tailings mixed with cement and other consolidating materials to the underground mining area for cementing filling (or water and sand filling) to form a backfill body that meets the standard strength.

Tailings Recovery Methods

Gravity Separation: This method uses the differences in density between the valuable minerals and the waste material. Techniques such as jigging, shaking tables, and spirals chute can separate heavy minerals from the lighter gangue.

Flotation: Flotation is a widely used technique in mineral processing to separate minerals based on their surface properties. In this process, chemicals are added to create a froth that selectively attaches to the valuable minerals, allowing them to be separated from the waste material.

Magnetic Separation: This method effectively separates minerals attracted to a magnetic field from those not. Magnetic separators can be used to recover magnetic minerals from tailings.

Leaching: Leaching involves using chemicals to dissolve the valuable minerals from the tailings. It is often used for recovering metals like gold and silver.

Biological Methods: Some researchers are exploring biological methods, such as using microorganisms, to extract metals from tailings selectively.

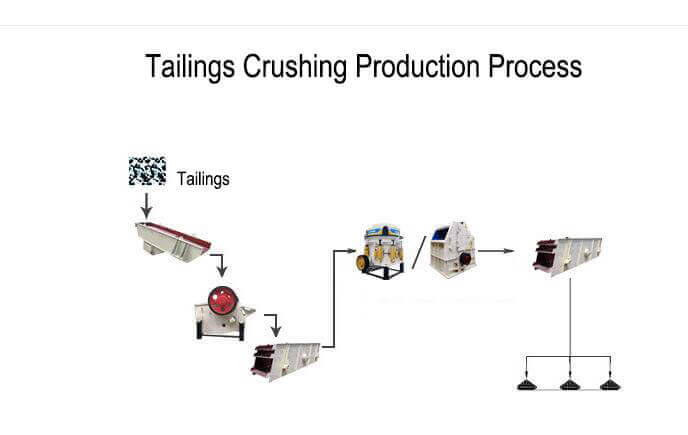

Tailings Crushing Production Line

[Applicable materials]: All kinds of ores

[Application fields]: Tailings recycling

[Equipment Configuration]: Jaw crusher, impact crusher or cone crusher, feeder, vibrating screen, magnetic separator, ball mill, etc.

LATEST PRODUCTS

Tubular Screw Conveyor

【Capacity】6-50 m3/h【Procesible Material】 …

Heavy Plate Feeder

Capacity: 100-240 m3/h Power: 15-45 kW Speed: 0…

Plate Magnetic Separator

【Capacity】8-35 t/h 【Power】1.5-3 kW 【Applic…