Fluorite Ore Type

The different gangue minerals can divide fluorite ore into four types:

- Quartz-type fluorite ore

- Carbonate-type fluorite ore

- Barite-type fluorite ore

- Sulfide fluorite ore

(1) Quartz-type fluorite ore: The main minerals are fluorite and quartz, and the fluorite content can reach 80% to 90%. It contains a small amount of calcite, barite, and sulfide.

(2) Carbonate type fluorite ore: The main minerals are fluorite and calcite. The content of calcite can reach more than 30%, and there is a small amount of quartz, sometimes composed of quartz, calcite, and fluorite type ore.

(3) Barite-type fluorite ore: The main minerals are barite and fluorite, and the barite content reaches 10% to 40%. It often accompanies this type of ore by pyrite, galena, sphalerite, and other sulfides, and sometimes the range of quartz increases, forming a quartz-barite-fluorite type ore.

(4) Sulfide-type fluorite ore: Its mineral composition is the same as that of quartz-fluorite, but it contains more metal sulfides, and sometimes the content of lead and zinc can reach industrial grades.

How to Beneficiate Fluorite Ore?

Currently, it mainly uses the flotation method for beneficiation and purification of fluorite at home and abroad.

1. Quartz-Fluorite

Quartz-type fluorite ore is mainly composed of fluorite (about 85%) and quartz, with only a small amount of calcite, barite, and sulfide.

The key to the selection is mainly to reduce silicon in concentrates.

To separate quartz from fluorite, it is necessary to dissociate the quartz and fluorite monomers through grinding, so grinding is an essential factor affecting the flotation of quartz-type fluorite. If the grinding particle size is too coarse, the conjoined body of quartz and fluorite exists in the product, making the rough concentrate after flotation too high. Suppose the grinding particle size is too fine. In that case, although it dissociates the quartz and fluorite individually, it will lead to excessive fluorite crushing in the grinding product and reduce the recovery rate of fluorite.

The most reasonable method is to use a stage grinding process, which can reduce the silicon content in the fluorite concentrate after flotation and increase the fluorite concentrate’s recovery rate.

This type of fluorite ore can be divided into two kinds, coarse-grained and fine-grained, according to the inlaid characteristics of valuable minerals.

Coarse-grained embedded fluorite is easy to select. The fatty acid type collector is used, the slurry adjuster is sodium carbonate, and the quartz inhibitor is water glass. It can obtain high-quality fluorite concentrate through a coarse and multi-fine process.

The flotation reagents of the fine-grained embedded quartz-type fluorite ore are the same as those of the coarse-grained embedded quartz-type fluorite ore. Still, due to the small embedded particle size of the target minerals, it is necessary to strengthen the grinding and use the stage grinding stage for separation process flow.

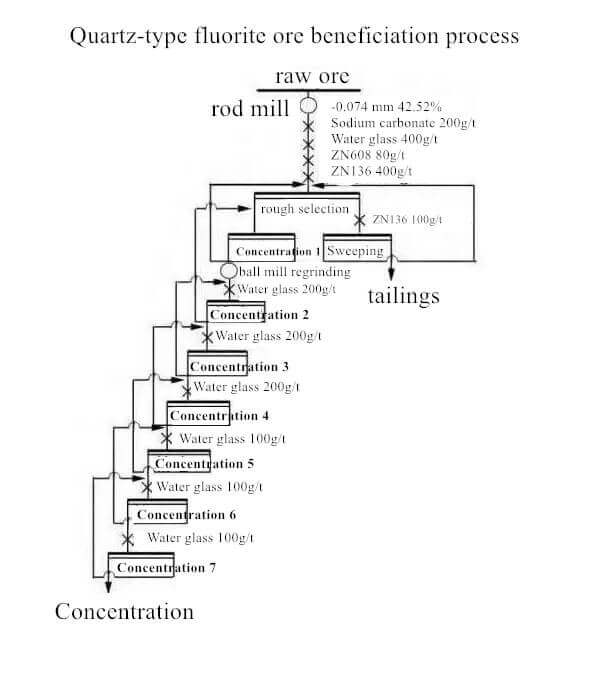

Quartz-type fluorite beneficiation

Quartz-type low-grade fluorite ore, the main recoverable mineral is fluorite with a grade of 30%, and the main gangue mineral is quartz, followed by calcite, feldspar, mica, etc.

Process parameters: rough dressing and grinding fineness is -200 mesh(accounting for 42.52%). It uses water glass + ZN608 as an inhibitor and fluorite low-temperature collector ZN136 as a collector. It uses one coarse, one sweep, and seven fine. And one-stage concentrate regrinding and middling return to a closed-circuit process that can obtain fluorite concentrate with a CaF2 grade of 97.45% and a recovery rate of 92.71%.

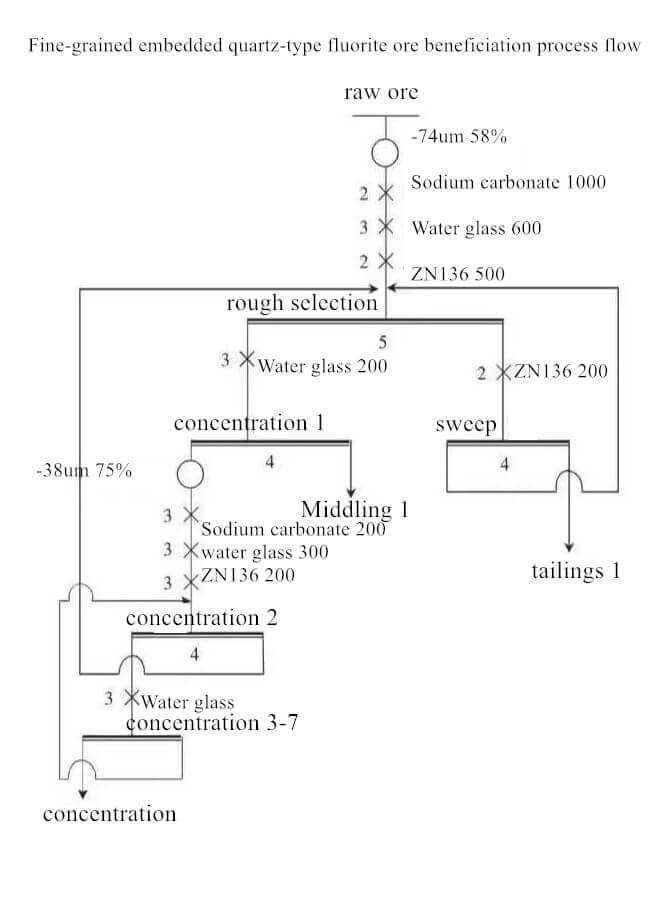

Fine-grained embedded quartz-type fluorite ore beneficiation

The fine-grained inlaid quartz-type fluorite ore has a fluorite content of 32.75%. The inlaid relationship between fluorite and quartz in the ore is complex, and the inlaid granularity is small. Fine grinding is required to dissociate the fluorite and quartz monomers.

Process parameters

The experimental research adopts the process of one roughing, one sweeping, and seven beneficiations.

One-stage middling cast tails directly, flotation concentrate of one-stage concentrate regrind and refloat. It uses the self-developed ZN136 as the fluorite low-temperature flotation collector. Under the condition that the slurry temperature is 5~10℃, the beneficiation index obtained by the laboratory is the fluorite feed CaF2 32.52%, the concentrate CaF2 97.55%, and SiO2 1.36%, the fluorite recovery rate is 76.67%. Under the slurry temperature at 5℃, the industrial production index is fluorite feeding CaF2 30.14%, concentrate CaF2 97.37%, SiO2 0.81%, fluorite recovery rate 89.67 %.

2. Calcite-fluorite

Calcite-type fluorite ore is mainly composed of fluorite and calcite (content up to 30% or more), with a small amount of quartz, which can form quartz-calcite-fluorite-type ore.

The main reason calcite-type fluorite ores are difficult to separate is that both calcite and fluorite are calcium-containing minerals with similar surface physical and chemical properties.

Both fluorite and calcite are calcium-containing minerals, and their solubility is similar. Therefore, the flotation separation of such ores is difficult. The selection of suitable collectors and inhibitors is the key to achieving the separation of fluorite from calcite. At the same time, proper process flow and process conditions are also essential factors in improving the flotation index. Combined and new agents are widely used in sorting this type of fluorite ore.

To achieve the separation of calcite and fluorite, it must adjust the pH value of the slurry and use a collector to achieve a good separation effect. Water glass, salted water glass, acidified water glass, sodium hexametaphosphate, lignosulfonate, dextrin, tannin, and calcium carbonate special inhibitor ZN608 can be used. It can use them alone or in combination to inhibit calcite for separation purposes.

3. Barite-fluorite

The main minerals of barite-type fluorite ore are barite and fluorite, and the barite content is 10% to 40%. It often accompanies this ore with pyrite, galena, sphalerite, and other sulfide minerals.

The difficulty in beneficiation of barite-type fluorite ore is that the float-ability of barite and fluorite is similar, which makes it difficult to separate the two.

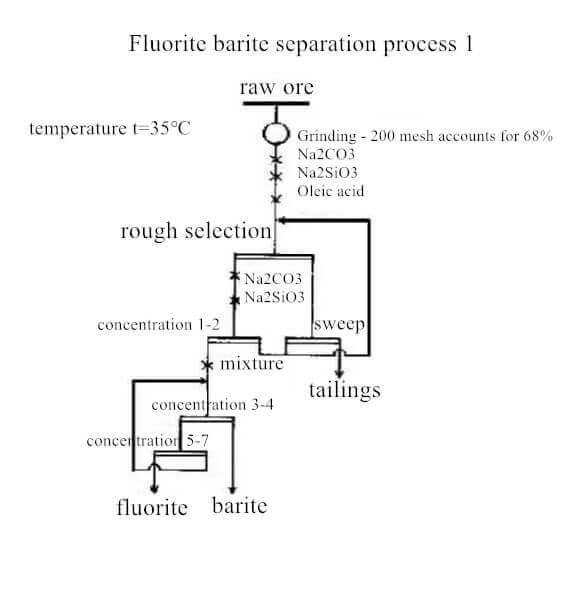

Mixing flotation and Na2CO3 adjust the slurry’s pH value in the flotation of barite-type fluorite ore. It uses oleic acid and water glass as collectors and inhibitors to obtain fluorite and barite. The concentrate is mixed and uses flotation to separate barite and fluorite.

The flotation separation process of barite-type fluorite ore is divided into two types: inhibiting barite from floating out of fluorite and inhibiting fluorite from floating out of barite. The key to flotation separation of barite and fluorite lies in the choice of inhibitor.

Use of Combination Inhibitors 1

Using oleic acid as the collector, dextrin + ferric chloride as the combined inhibitor of barite, through 1 coarse one sweep seven fine flotation process, it can obtain the fluorite concentrate with a CaF2 grade of 97.87% and a recovery rate of 79.26%, barite concentrate with a BaSO4 grade of 94.62% and a recovery rate of 72.53%.

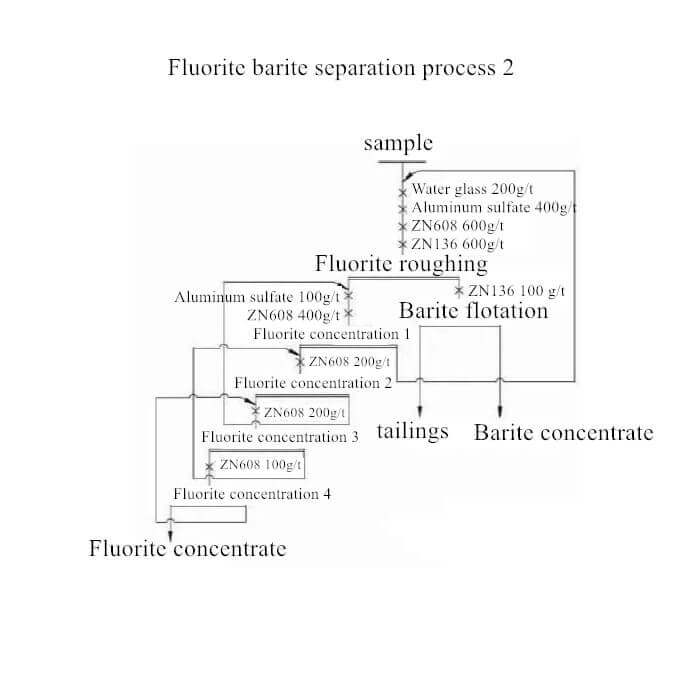

Use of Combination Inhibitors 2

ZN608 can selectively inhibit barite, and water glass can selectively inhibit quartz and improve the dispersity of pulp. Aluminum sulfate can not only assist in inhibiting barite but also weaken the inhibiting effect of water glass on fluorite. To achieve the purpose of inhibiting barite and quartz at the same time.

Process parameters: The mixed concentrate was treated with one coarse, four refined, one sweep, and selected medium ore returning to the process. It can obtain the fluorite concentrate with a CaF2 grade of 97.21%, a recovery rate of 85.44%, and a BaSO4 grade of 94.36%, the barite concentrate with a rate of 86.75% and a density of 4.25 g/cm3 has achieved high-efficiency separation of fluorite and barite.

The composition of sulfide ore-type fluorite ore is similar to that of quartz-type fluorite mineral. Still, the content of metal sulfide is higher, and sometimes the content of lead and zinc can reach industrial grade. Therefore, when developing and utilizing fluorite, we must also consider the recovery of metal ore.

Sulfide ore-type fluorite mines generally use sulfide ore collectors to select metal sulfide minerals preferentially and then use fatty acid collectors to recover fluorite from flotation tailings. In addition, it also can use processes such as roasting and leaching can to extract valuable metals and decompose fluorite. The process flow is relatively simple, and high-quality fluorite products can be prepared while comprehensively recycling valuable metals.

LATEST PRODUCTS

Twin Screw Feeder

【Feeding Capacity】 10-160 t/h【Power】 2.2-…

Tubular Screw Conveyor

【Capacity】6-50 m3/h【Procesible Material】 …

Heavy Plate Feeder

Capacity: 100-240 m3/h Power: 15-45 kW Speed: 0…