Building gravel & sand is the most widely used building material in road and bridge construction. It can be directly used in the construction application, and can also be processed into aggregates of various size apply in the asphalt and cement making.

According to the technical standards, the natural stone materials for road construction are divided into four grades to meet the different requirements of the construction site.

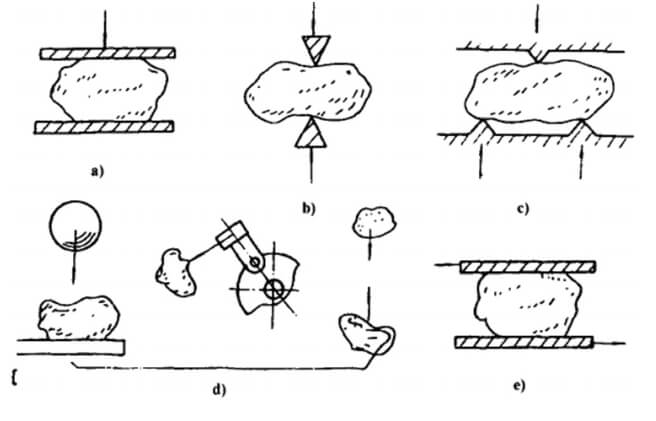

What are the crushing types?

Squeezing. The rock is subjected to pressure between the two planes, the force which exceeds the compressive strength of the stone makes the stone break into smaller pieces.

Split. Under the action of the wedge, the tensile stress is generated in the stone. When the tensile stress exceeds the tensile strength of the stone, then be broken.

Fracture. Under the action of multi – fulcrum staggered force, the stone is subjected to shear and bending stress. When these stresses exceed a certain limit, the stone will be sheer or bending broken.

What are the different types of crushers?

The crusher can be divided into three types according to the particle size of the feed and the final product. Primary crusher( from 1500-500mm to 350-100mm); secondary crusher( from 350-100mm to 100-40mm); tertiary crusher( from 100-40mm to 30-10mm).

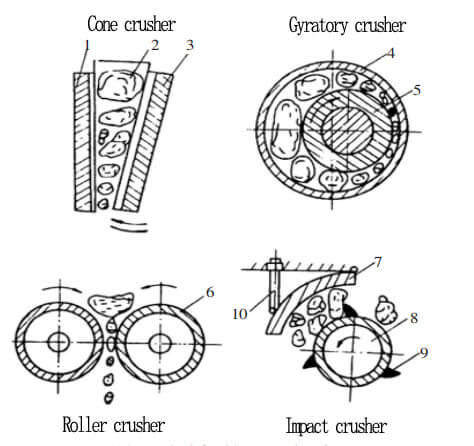

Crusher also can be classified according to the working principle and mechanical structure.

Jaw Crusher. When the movable jaw plate close to the fixed jaw plate, creates a squeezing force act on the stone. in addition, there is jagged steel on the rock material contacting surface of the fixed plate and Fracture. When the movable plate apart from the fixed plate, the crushed material is discharged under the gravity force.

The process of crushing is that the process of breaking large particle material into smaller size under the action of external force. In industry applications, the size reduction task mainly depends on the mechanical force.

Because of the jaw crusher working principle that crushes the material by reduced space between two plates, the aggregate product often has a high content of needle shape, which is not suitable for asphalt processing road construction. Therefore, the jaw crusher is widely used as primary crusher rather than secondary crusher in the mineral processing, aggregate processing industry.

What is the difference of gyratory crusher and cone crusher?

Conical crusher is a kind of compression crusher, which is mainly used for medium crushing and coarse crushing of hard stone.

LATEST PRODUCTS

Twin Screw Feeder

【Feeding Capacity】 10-160 t/h【Power】 2.2-…

Tubular Screw Conveyor

【Capacity】6-50 m3/h【Procesible Material】 …

Heavy Plate Feeder

Capacity: 100-240 m3/h Power: 15-45 kW Speed: 0…