What’s ore washing?

Ore washing is the process of by the use of water or mechanical force to agitate and scrub raw ore, wash and separate the clay from ore. The alluvial ore deposits ( like gold, platinum, tungsten, tin ) and other minerals such as lead, copper, iron and manganese which are deeply oxidized and weathered, usually need to be washed to remove some gangue or clay before crushing or beneficiation.

Why wash the ore?

1. The washing process is often as preliminary preparation before the crushing and other beneficiation steps. Washing mud and separating the coarse waste rock can increase the overall efficiency, and reduce the machine wear.

2. Washing can avoid the clogging the bin, crusher, and screening equipment, ensuring smooth flow.

3. Some ore’s slime and rocks are very different in terms of washability (such as floatability). Separation of ore slime and ore rock by washing process can obtain a better flotation effect. In this case, although washing is an auxiliary process, it has a significant impact on the entire production process.

4. For some alluvial residual manganese oxide ore, limonite ore, bauxite ore which contain only very little value minerals, separating them by washing can improve the mineral nugget grade.

5. The washing, scrubbing and classifying process is also suitable for weathered siliceous phosphate rock, kaolin processing.

Clay properties affect to select ore washer machine

The washability of ore is related to clay plasticity, water content, expansibility, permeability, and ore grain size composition. The smaller the plasticity of the clay, the stronger the expansion and permeability, the easier the ore is washed. The more the content of the rock materiale, the greater the impact agitation in the ore washing, and the more rapid the washing.

| Difficulty of ore washing | Clay property | Clay plasticity | Power Consumption | EXPTIME | Wash method |

| Easy | 1-7 | <5 | <0.25 | vibrating screen | |

| Medium | finger can separate it | 7-15 | 5-10 | 0.25-0.5 | cylinder sieve scrubbing machine |

| Hard | clay consolidate, not easy separate by finger | >15 | >10 | 1-5 | spiral groove ore washing machine |

Ore washing machines

Add a high-pressure water pipe on the grizzly screen, vibrating screen, rotary screen, and the like ore screening machine, simultaneously do screening and washing.

Ore washer machines have spiral washing machines, trommel scrubber machines, hydraulic washing sieve, cylinder washer, and trough washer.

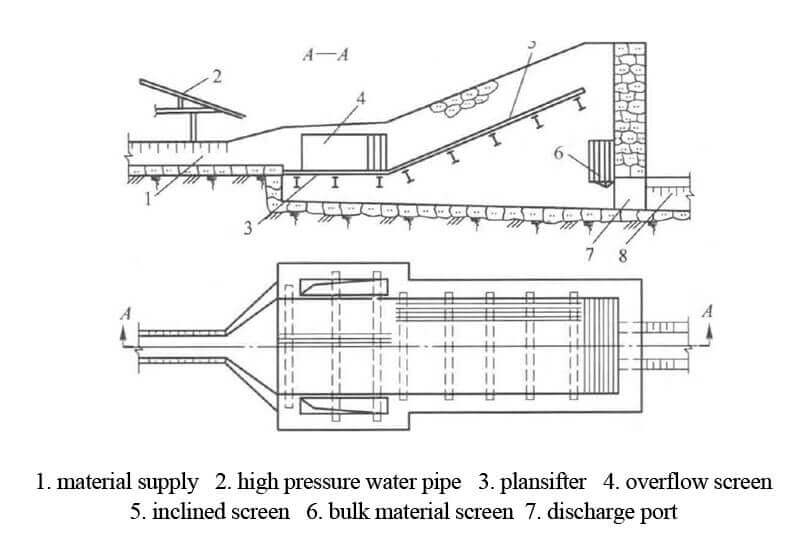

1. Hydraulic washing screen

Main parts of hydraulic washing screen: high pressure water gun, flat screen, overflow screen, inclined screen and large material screen.

The flat screen and the inclined screen are about 3m wide, the flat screen length is 2~3m, the inclined screen length is 5~6m, the inclination angle is 20°~22°, and the large material screen tilt angle is 40°~45°. The overflow screen on both sides is perpendicular to the plane screen, and the screen strip is made of round steel of 25 ~ 30mm, and the spacing is generally 25 ~ 30mm.

The hydraulic washing screen has a simple structure, large production capacity, and easy operation.

Disadvantages: The water gun requires high water pressure and high power consumption; it has a low ability to break up small agglomerates.

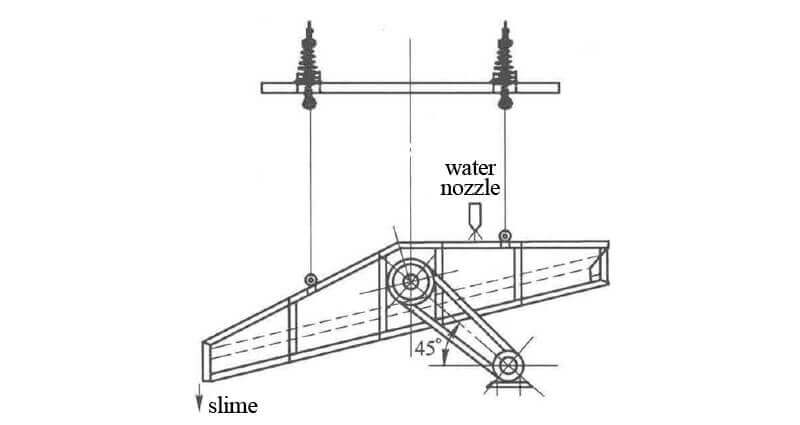

2. Vibrating washing screen

vibrating screen product

Mine use vibrating screens often adopts double-layer screens for screening medium and fine crushed ore.

Add a high-pressure water flushing device on the fixed screening machine. The flushing water pressure is generally 0.2-0.3 MPa, and the water consumption per ton of ore is 1 ~ 2 m3.

When the raw ore contains little mud and the cohesiveness is not strong, the use of such combination can meet the requirements of washing.

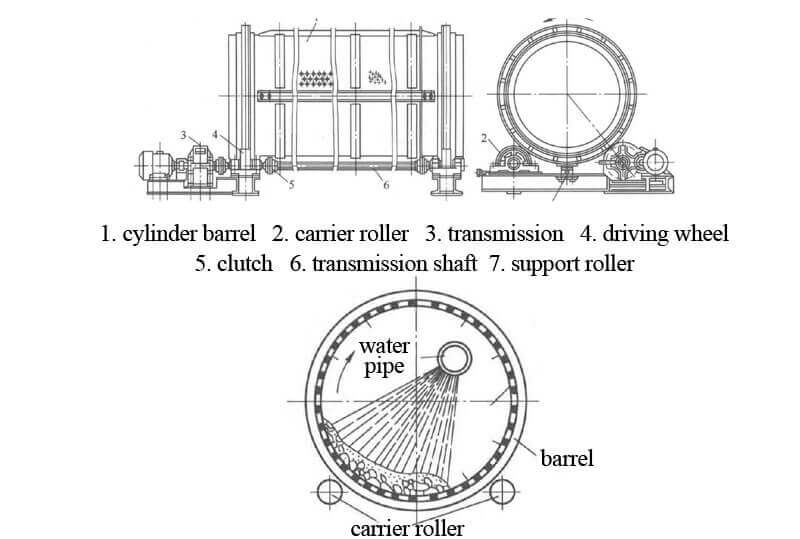

3. Cylinder trommel screen

Cylinder trommel screen product

Its cylinder is made of steel, woven mesh, or steel rods. A high pressure flushing water pipe is arranged in the longitudinal direction of the cylinder. With the rotation of the cylinder screen, the ore blocks are turned over and collided with each other, and the ore and clay dispersed. Built in impeding plates, chains can enhance the washing effect.

The diameter of the cylinder is 1. 0~3.0m, the length is 3. 0~ 7.5m, the rotation speed of the cylinder is 15-30r/min, and the production capacity is 30~400t/h.

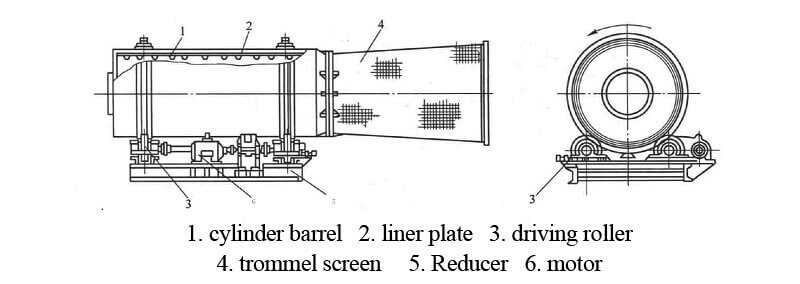

4. Trommel screening attrition scrubber

Trommel screening attrition scrubber

Trommel screening attrition scrubber is suitable for handling medium washable ores up to 300 mm.

The cylinder barrel of attrition scrubber is non-porous, the cylinder and the inner wall are provided with manganese steel or rubber lining, and the lining plate has ribs to form a spiral with the pitch gradually increasing toward the discharge end, which can make the material disperse and the material is moved towards the discharge end. The cylinder is rotated by the friction of the metal roller or the rubber tire.

Usually, the attrition scrubber need a fill rate of up to 25%. The ore and water enter the cylinder barrel at the same time from the feed port, reaching a certain concentration (solid mass fraction of 40% ~ 50%), so that it has sufficient fluidity. At the same time, a fixed nozzle water pipe can be disposed in the body of the scrubbing machine, and the water pressure is generally 0.1 to 0.2 MPa.

For easy-to-clean ore, the scrubber should use a lower speed (3o% – 4o% critical speed), for the haigh plastic clay ore, the scrubber should use a high speed (70% ~ 80% critical speed).

When the cylinder rotates, the material forms a waterfall movement in the scrubber, causing the ore to fall off and generate strong friction, forcing the disintegration of the highly plastic clay material. Therock material flushed by the high pressure water is discharged from the discharge port along with the slurry flow, and flows into the cantilever tapered cylindrical sieve installed on the scrubber to achieve sufficient separation of the mud and the rock material.

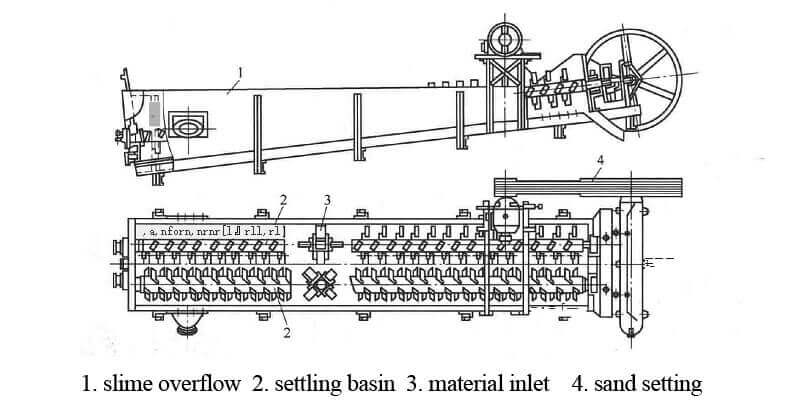

Trough washing machine

The structure of the trough washer is similar to that of a spiral classifier in that it has two long axes in a nearly semi-circular chute with discontinuous agitating blades.

The apex of the blade is a spiral, the diameter of the spiral is 800mm, and the pitch is 300mm. The two spirals rotate in opposite directions, and the upper blades are all rotated outward.

The slurry is fed from the lower end of the tank, and the cement of the ore is cut, scrubbed, and washed by the high-pressure water fed from the upper end, and the clay and the nugget are released. The clay forming slurry is discharged from the lower overflow tank, and the coarse material is pushed by the blades and discharged from the discharge port at the upper end of the tank.

The trough type washing machine has strong cutting and scrubbing ability, and has strong ability to break up small mud masses. It is suitable for the treatment of difficult to wash ore with less ore density, medium grain size and more mud. It has high processing capacity and high washing efficiency; the disadvantage is that the size of the ore washed is limited, generally not more than 50mm, otherwise the spiral blade is easily broken or even broken.

The trough washing machine with the specification of 6660mm x 1500mm has a tank volume of 6m3. The capacity of the slope alluvial tin mine is 800~1100t/d, and the water consumption per ton of ore is 4~6m3.

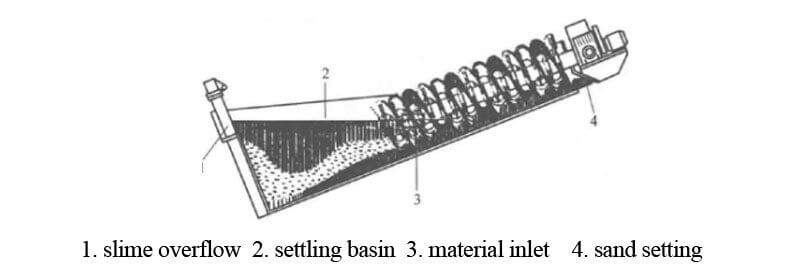

Spiral classifier

Spiral classifier product

Spiral classifier can be used as a ore washer. But because it is not very strong in breaking and dispersing, it is mainly used for processing slime and sand products discharged from other ore washing equipment and further removing the mud.

Ore washing process flow

There are basically two types of ore washing processes:

The first is “ore washing + slime and rock separating process”, consisting of ordinary screening machinery (grizzly sieve, vibrating screen, trommel screen, etc.) and spiral classifier;

The second is the process consisting of specialized washing equipment.

The former “ore washing + slime and rock separating process” is usually combine with crushing circuit, the screening equipment is play role both in crushing & grinding plant, and washing & screening plant, saves cost. It is suitable for treating ore with little amount, low plasticity and little agglomeration clay.

However, for those ore with more clay, high plasticity and agglomerate, it is necessary to use special washing equipment, and it is necessary to carry out 2 or even 3 times of washing to separate the clay from the ore.

Behind the washing process, there often followed by slime concentration operation, mainly using sloping plate grading thickener, deep cone thickener, vertical sand silo and other equipment, and the overflow water from the concentrated operation returns to the washing plant.

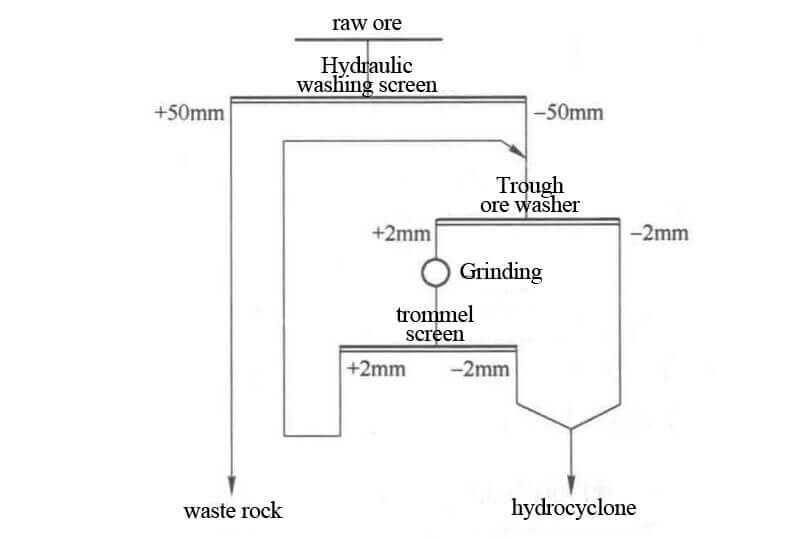

Case – Alluvial tin washing flow

Raw alluvial tin composition

Contains 0.329% tin and 26.68% iron. It does not contain value minerals in the +50mm grain grade.

Size distribution

The -2mm size accounts for 88.42%, and the -0.074mm size accounts for 59.96%. Many of them are highly cohesive, bonded together with ore rock, which is difficult wash ore.

Washing process flow

LATEST PRODUCTS

Twin Screw Feeder

【Feeding Capacity】 10-160 t/h【Power】 2.2-…

Tubular Screw Conveyor

【Capacity】6-50 m3/h【Procesible Material】 …

Heavy Plate Feeder

Capacity: 100-240 m3/h Power: 15-45 kW Speed: 0…