What Should You Know before the Fracture of Vibrating Screen Cross Member?

The vibrating screen is the most used type of material screen in the appliance of aggregate processing, coal processing, mineral processing plant, tailings management, washing and sizing task. Incline vibrating screen usually equipped with two, three or more layers of decks. What should every machine operator know before the fault will occur? Let’s start from the cross member. vibrating screen for sale

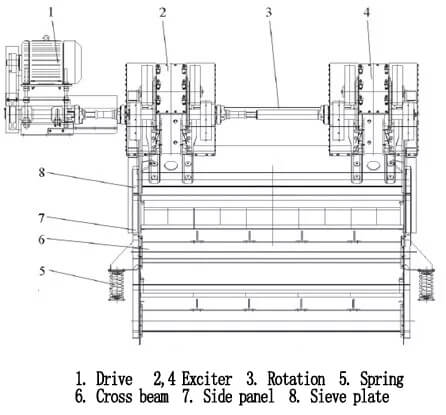

1 Structure and working principle

The main parts are drive, screen, vibration exciter, bumper, transmission, spring, side panel.

The cross member is the main component of the screen body and is made of the hollow rectangular steel tube. The rubber layer of the beam outer surface can prevent it from the erode and can reduce the noise efficiently. The crossbeam crack of the vibrating screen which has just been put into production shows that the problem existing in the screen body.

2 Fault diagnose

2.1 Deformation of the connecting shaft between the two exciters

There is required synchronization motion of two exciters if the shaft connecting the two exciters goes wrong, one of the exciters is work advanced or lags, will cause asynchronized vibration, thereby, the nonuniform force on the left and right sides do harm to the cross beam.

Coping approaches: check for deviation at both ends of the connecting shaft, adjust or replace the shaft.

2.2 The problem of exciter its own

Should better not use two exciters from two different suppliers, avoid the deviation problems of exciters its own.

2.3 Nonuniform feed, unbalance loading

Unbalance loading make the angle difference of two sides oversized, thus the cross beam wear and breaks prematurely.

2.4 Heavy impact force of feeding

The high drop of the feeding groove causes a heavy impact that damages the cross beam directly. meanwhile, the excessive impact force also brings about vibration which may have an influence on the performance.

coping approaches: add a dash plate in the middle of the material groove, under the condition of non-blocking, minimize the drop height along with impact force.

2.5 Overloading

Due to the inappropriate equipment configuration, some screen machines are operated for a long time under the overload condition, the screening and dissociation effects are detracted, in addition, the springs and crossbeam is broken easily.

Coping approaches: it is recommended to enlarge the sieve hole or sieve joint. For the horizontal vibration screen, to raise the feed inlet height, increase the material flow volume so that heighten the processing capacity.

2.6 Sieve plate loosening

The loose sieve plate direct affects the cross beam, and also changes the sieve frequency, which may cause the rotation speed approach the critical point, do a severe damage to the machine.

Coping approaches: regularly check the sieve plate and base, tighten the bolts, and replace the worn sieve parts.

2.7 The quality of the cross beam

The quality of the cross beam is closely related to the welding process and the tempering after welding. If the welding stress is not eliminated, it occurs fracture at the weld place easily.

From the analysis of the causes of the above mentioned vibrating screen cross beam fracture, it can be seen that except for a small part due to the intrinsic quality, most of it is caused by the operation and maintenance. So in the production site, the correct operation and maintenance are necessary to know well to ensure safe and efficient.

LATEST PRODUCTS

Twin Screw Feeder

【Feeding Capacity】 10-160 t/h【Power】 2.2-…

Tubular Screw Conveyor

【Capacity】6-50 m3/h【Procesible Material】 …

Heavy Plate Feeder

Capacity: 100-240 m3/h Power: 15-45 kW Speed: 0…