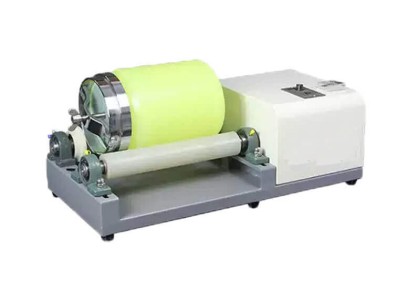

Laboratory Jar Mill

【Volume】: 0.5-30L

【Quantity】: 2-8 adaptive Jar

【Application】: It’s widely used in laboratories or fine-grinding small electronic materials, magnetic materials, equipment batteries, biological culture, food packaging, and battery materials.

Chat Online on WhatsApp

Chat Online on WhatsAppAdvantages

Lab jar mill is called drum pot mill, roller ball mill, or rolling mill with more than two working positions. The laboratory jar mill is a kind of ultra-fine grinding equipment used for dry grinding and wet grinding in laboratories and small batch production and mixing, homogenizing and dispersing. The machine is exquisite in design, easy to operate, highly efficient, and uniform in particle size. It is the first choice for scientific research, education, experiment and production. It is widely used in producing small enterprises such as electronic materials, magnetic materials, biomedicine, ceramic glazes, metal powders, non-metallic minerals, and new materials. The machine adopts the speed optimization design. The grinding tank is dragged and rotated by the rubber roller, and the ball in the tank makes an oblique flow movement and disperses the material. So as to obtain the best grinding effect.

(1) Grinding tank material selection: nylon, corundum/alumina, stainless steel, polyurethane and other special materials;

(2) Selection of grinding ball materials: stainless steel balls, alumina balls/corundum balls, agate balls, zirconia balls, hard alloy balls, etc.

We can also customize a laboratory jar mill based on special customer requirements. Contact us!

【Features】

- Single or multiple slots can be used at the same time, and more kinds of sample materials can be ground each time;

- Timing control panel is adopted, with pause and accumulative timing control functions, and the working time can be set according to needs;

- It can be operated intermittently or continuously, saving time and effort;

- Suitable for material fine grinding, crushing, mixing, anti-sedimentation and other process requirements, with high efficiency;

Roller spacing can be easily adjusted to accommodate different sized jars.

Product Structure

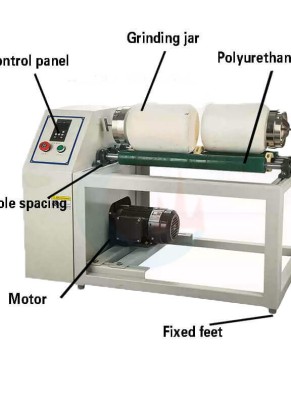

【Structure】

The laboratory jar mill mainly consists of grinding jar control panel, polyurethane roller, powerful motor, adjusting hand wheel and other parts.

【Working Principle】

The Jar ball mill is driven by a main shaft covered with wear-resistant rubber parts, and the main shaft is connected with the motor pulley through a pulley. The outer wear-resistant rubber part on the main shaft moves relative to the tank body, that is, it rubs against the surface of the ball mill tank body, and drives another driven shaft to realize rolling. The grinding medium and the cylinder material rotate to a certain height. Under the action of gravity, they break away from the cylinder wall and fall along a parabola. The material is pulverized under the impact of the grinding medium and the friction caused by the rolling and sliding of the grinding medium.

Technical Parameters

| Model | Adaptive Jar | Tiers | Roller shafts | Available jar diameter(mm) | RPM | Voltage (V) | Working power (KW) | Dimensions | Transmission mode | ||||

| Volume | Quantity | Quantity (per tier) | Diameter | Length | Adjustable spacing | (L*W*H/ mm) | |||||||

| GMS1-2 | 0.5-1L | 2 | 1 | 2 | φ40 | 180 | 52~160 | φ50-φ160 | 0~300 | 220V | 0.75 | 580*420*410 | Belt |

| GMS3-2 | 0.5-3L | 2 | 1 | 2 | φ50 | 220 | 52~210 | φ50-φ200 | 0~300 | 220V | 0.75 | 660*440*410 | Belt |

| GMS5-1 | 0.5-5L | 1 | 1 | 2 | φ60 | 390 | 67~280 | φ70-φ260 | 0~270 | 220V | 0.75 | 500*350*320 | Belt |

| GMS5-2 | 0.5-5L | 2 | 1 | 2 | φ60 | 390 | 67~280 | φ70-φ260 | 0~270 | 220V | 0.75 | 760*610*530 | Belt |

| GMS10-2 | 0.5-10L | 2 | 1 | 2 | φ70 | 390 | 67~230 | φ60-φ280 | 0~220 | 220V | 1.5 | 790*630*530 | Synchronous belt |

| GMS20-2 | 0.5-20L | 2 | 1 | 2 | φ80 | 470 | 30~340 | φ60-φ320 | 0~220 | 380V | 2.2 | 827*952*724 | Synchronous belt |

| GMS30-2 | 1-30L | 2 | 1 | 2 | φ80 | 425 | 35~290 | φ60-φ360 | 0~200 | 380V | 2.2 | 1328*658*720 | Synchronous belt |

| GMS1-4 | 0.5-1L | 4 | 1 | 3 | φ40 | 180 | 62~160 | φ50-φ160 | 0~300 | 220V | 0.75 | 580*520*410 | Belt |

| GMS3-4 | 0.5-3L | 4 | 1 | 3 | φ50 | 230 | 76~230 | φ70-φ180 | 0~270 | 220V | 0.75 | 780*648*530 | Belt |

| GMS5-4 | 0.5-5L | 4 | 1 | 3 | φ60 | 390 | 67~280 | φ70-φ260 | 0~270 | 220V | 1.5 | 850*748*530 | Belt |

| GMS10-4 | 0.5-10L | 4 | 1 | 3 | φ70 | 390 | 67~230 | φ60-φ280 | 0~220 | 380V | 2.2 | 1189*890*680 | Synchronous belt |

| GMS10-4B | 0.5-10L | 4 | 2 | 2 | φ70 | 390 | 67~230 | φ60-φ280 | 0~220 | 380V | 2.2 | 742*890*1111 | Synchronous belt |

| GMS20-4 | 0.5-20L | 4 | 2 | 3 | φ80 | 470 | 30~340 | φ60-φ320 | 0~220 | 380V | 2.2 | 1309*1128*724 | Chain wheel |

| GMS30-4 | 1-30L | 4 | 1 | 3 | φ80 | 425 | 35~290 | φ60-φ360 | 0~200 | 380V | 4 | 1328*1048*680 | Synchronous belt |

| GMS3-8 | 0.5-3L | 8 | 2 | 3 | φ50 | 230 | 76~230 | φ70-φ200 | 0-280 | 380V | 1.1 | 780*717*965 | Belt |

| GMS5-8 | 0.5-5L | 8 | 2 | 3 | φ60 | 310 | 67~280 | φ70-φ260 | 0-270 | 380V | 2.2 | 1020*868*950 | Chain wheel |

| GMS10-8 | 0.5-10L | 8 | 2 | 4 | φ70 | 410 | 67~302 | φ60-φ280 | 0~220 | 380V | 3 | 1210*890*1050 | Chain wheel |

| GMS20-8 | 0.5-20L | 8 | 2 | 4 | φ80 | 470 | 30~340 | φ60-φ320 | 0~220 | 380V | 3 | 1390*1128*1100 | Chain wheel |

Successful Cases

Contact Us Now

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours. Rest assured that we won’t reveal your information to anyone.