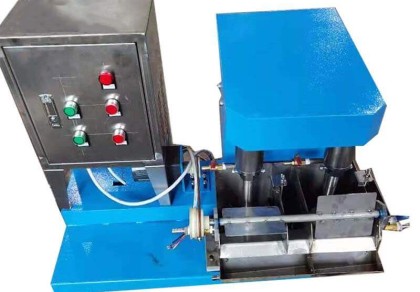

Mechanical Agitated Continuous Flotation Machine

【Feeding size】≤0.2 mm

【Cell Number】2 PCS

【Application】Use for flotation of a small number of ore samples in industrial experiments such as coal power, electric power, mining, geology, chemistry, metallurgy, building materials, and chemical industry.

Chat Online on WhatsApp

Chat Online on WhatsAppAdvantages

FX mechanical agitated continuous flotation machine is suitable for continuous flotation tests or semi-industrial production tests of a small number of minerals in the laboratory by the flotation method. It comprises several units, and the number of cells is even. Left feed configuration or right feed configuration is available upon request.

The FX2 mechanical agitation continuous flotation machine can form a series group and work continuously. So it is more accurate and applicable than ordinary single-slot flotation machines to process ore samples.

Features

- The selection tank, scraper, and impeller assembly are 304 stainless steel.

- Each flotation machine can be equipped with a frequency converter, and a liquid control valve is installed between the two tanks.

- Each machine has a separate controller controlling each machine’s different speeds.

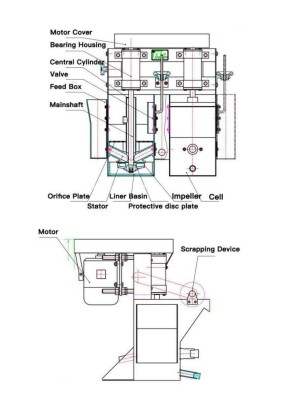

Product Structure

【Structure 】

FX impeller continuous flotation machine is a self-aspirating mechanical agitated flotation machine, composed of cells, a main shaft part, an impeller system, and a foam scrapping device.

【Working Principle】

The two tank wall panels make the medium tank adjust the liquid level of the tank's slurry, and the foam layer's thickness is scraped out. Install a slurry level regulator and install an orifice plate on the tank's cover to prevent the slurry's chaotic movement from affecting the foam area and prevent the gangue from being brought into the concentrate by machinery. There is a liner on the tank body to avoid wear on the bottom of the tank. The liner can be replaced. An ore discharge port is outside the tank bottom for water discharge during cleaning. The ore slurry flows through the overflow port on the wall plate into the medium tank and the tail tank, and the lower part of the medium tank and the pipe covered by the lower part of the tank wall enter the next tank so that it can continue to flow through all the tanks of the flotation machine. The ore tank flows in and is discharged from the ore discharge port of the tail tank. There are ore inlet ports at the front and back of the lower part of the tank body, which is convenient for changing the process flow.

Technical Parameters

| Model | FX2-1.5 | FX2-3 | FX2-7 | FX2-12 | FX2-24 | FX2-39 | |

| Cell Volume (L) | 1.5 | 3 | 7 | 12 | 24 | 39 | |

| Cell Quantity | 2 | ||||||

| Impeller Diameter (mm) | Φ70 | Φ70 | Φ110 | Φ130 | Φ170 | Φ200 | |

| Impeller Speed (r/min) | 1400 | 1332,1600,1836 | 1320 | 1100 | 447, 618, 787 | 809 | |

| Scraper Speed (r/min) | 33 | 20,30 | 20,30 | 24 | 12,16,20 | 13,21 | |

| Feeding Size (mm) | ≤0.2 | ||||||

| Power (W) | 250 | 250 | 370 | 600 | 1100 | 1500 | |

| External Size | Length (mm) | 378 | 500 | 623 | 740 | 942 | 1081 |

| Width (mm) | 406 | 500 | 590 | 600 | 804 | 762 | |

| Height (mm) | 523 | 600 | 750 | 700 | 925 | 930 | |

| Weight (kg) | 25 | 40 | 55 | 85 | 260 | 280 | |

Successful Cases

Contact Us Now

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours. Rest assured that we won’t reveal your information to anyone.