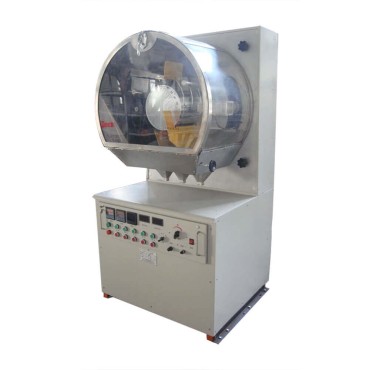

Laboratory Electrostatic Separator

【Capacity】: 15 – 30 kg/h

【Process Material Size】: 0.04-1mm

【Ore Feeding Method】: Upper feeding

【Application】: Used for the separation of conductor minerals and non-conductors

Chat Online on WhatsApp

Chat Online on WhatsAppAdvantages

JXSC Lab XDF-φ250×200 high-voltage electric separator is mainly used for the separation of conductive minerals and non-conductive minerals. It can also replace the screening operation for the classification of the same material and grain processing and partial selection work.

Laboratory Electrostatic Separator Features

- High voltage step-less adjustable (0-60,000V).

- Optional metal and non-metal materials.

- Simple operation and smooth operation.

- Beautiful appearance, stainless steel silo and hopper.

- Single-phase power supply is used, which reduces the requirements for power supply, and is safe and easy to use.

- The use of imported programmable controllers and frequency converters makes the electrical performance of the whole machine excellent.

- The digital display instrument is adopted, and various measurement data can be displayed eye-catching.

Lab High-voltage Electrostatic Separator Applications

- Selection of non-ferrous, ferrous, and rare metal ores.

Separation of scheelite and cassiterite; separation of magnetite, hematite, chromite, manganese ore; separation of tantalum niobium ore, ilmenite, rutile, monazite; separation of gold, etc. - Sorting of metal minerals.

Separation of quartz and feldspar; separation of graphite, diamond, apatite, coal, and asbestos. - Production of Ultra Pure Iron Concentrate

- Sorting of various materials: Classification can be carried out according to the shape and particle size of the materials.

- Sorting of broken metal powder, fine particles and other insulating materials.

- Remove non-ferrous metal substances from plastics.

- Recovery of useful metals such as copper and aluminum from municipal solid waste.

- Selection of grain and other grains to remove impure hybrids.

- Tea Sorting

Electric separation can be widely used in various fields on a large scale because the corona electric field plays a significant role. Compared with the previous electrostatic separation, the high-voltage electric field of the electric separation machine produced by our company can reach 60KV at the same time. Other sorting is more environmentally friendly and provides a broader development field for material separation applications.

Product Structure

Structure

The lab electrostatic separator XDF-φ250×200 is mainly composed of the main, transmission part, electrical equipment, separation hopper, drum electrode, hair brush, feeder, stock bin, and safety protection cover.

Working Principle

When the material is taken into the high voltage electric field that is affected by the corona electrode and polarity by rotating drum, the material is impacted by all kinds of electric power (including coulomb force, non-electric field force, and Interface suction), centrifugal force, gravity. Because of the difference in the electrical property of the different materials, the difference in the stress state results in the difference in dropping the track, which achieves the separation aim.

In the effect of the high voltage electric field, the load-carrying behavior of the Conductor and Non-conductor material: After the Conductor material absorbs the electric charge, it will be removed. Under the effect of centrifugal force and gravity, it drops down along the drum rotation direction; Because of the bad electrical conductivity of the non-conductor material, it can not be quickly taken away after it absorbs the electric charge in the high voltage electric field, it will be generated interface suction force with the drum face. This force is bigger than the joined forces of centrifugal force and gravity. So the non-conductor material is sucked tightly on the drum until the brush takes it down. The material between the non-conductor material and conductor material drops in the middle, it is called neutral material.

Technical Parameters

| Model | XDF-250×200 | |

| Drum Size(D*L) | φ250×200 mm | |

| Drum Speed | 50-300 r/min | |

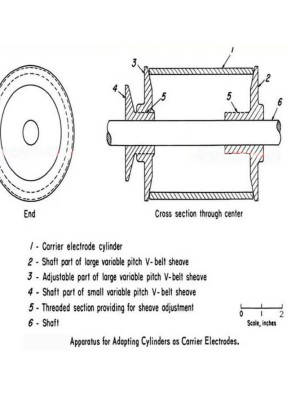

| Corona Electrode(electrode wire diameter x qty) | 0.2mm; 1-5pcs | |

| Static Electrode(diameter x qty) | 30mm, 1pcs | |

| Electrode Control | Radial Displacement | 50mm |

| Circumferential Angle | 60° | |

| Bush(external diameter x core diameter) | 105 x 60 mm | |

| Bush Speed | 100-600 r/min | |

| Drum Heating | Temperature | 50-60℃ |

| Power | 900W | |

| Bunker Heating | Temperature | 100-300℃ |

| Power | 900W | |

| Bunker Opening Scale | 0-20mm | |

| Feed Chute Inclinatioin | 2°- 30° | |

| Process Material Size | 0.04-1 mm | |

| Process Capacity | 15-30 Kg/h | |

| High Voltage Power Supply | 800W | |

| Maximum Voltage | 60Kv | |

Successful Cases

Contact Us Now

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours. Rest assured that we won’t reveal your information to anyone.