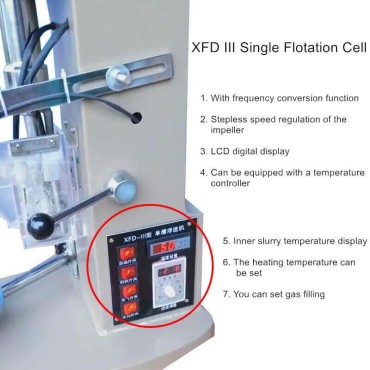

XFD Ⅲ Single Flotation Cell

【Impeller Speed】0-2800 r/min

【Feeding size】<0.25 mm

【Temperature Adjustment Range】50-95 ℃

【Application】Geology, metallurgy, building materials, chemical industry, and other mines and scientific research institutions laboratories are used for stirring, scrubbing, separating, and selecting a small number of ore samples, etc.

Chat Online on WhatsApp

Chat Online on WhatsAppAdvantages

The laboratory XFDⅢ single flotation cell is used by mines of geology, metallurgy, building material, chemicals, etc, and laboratories of scientific institutes to agitate, scrub, separate, and select a small number of ore samples.

The new model aeration single flotation cell of XFD Ⅲ is an updated product of the XFD model single flotation cell, adopting an external aeration device, adjustable aeration, frequency conversion technology, step-less speed governing of impeller digital display with accurate adjustment and reliable operation(When temperature for temperature control device ≤100℃, it can be made in accordance with customer’s need).

【XFD Ⅲ Single Flotation Cell Feature】

- With the frequency conversion function

- Stepless speed regulation of the impeller

- LCD digital display

- It can be equipped with a temperature controller

- Inner slurry temperature display

- The heating temperature can be set

- You can set gas filling

Product Structure

【Structure】

The XFD Ⅲ flotation machine is composed of a frame part, main shaft drive part, lock part, scraper part, flotation cell, outside air inflation device, electric controller, etc.,

【Working Principle】

The single-cell flotation machine (mine-use single-cell flotation machine) is driven by the triangular transmission of the motor to rotate the impeller, which generates centrifugal action to form a negative pressure. Mineralized foam, so that minerals adhere to the foam, float to the surface of the slurry and then form mineralized foam. Adjust the height of the ram to control the liquid level so that the scraper scrapes off the valuable foam.

Technical Parameters

| Model | Cell Vol.(L) | Impeller Diameter(mm) | Impeller Speed(r/min) | Scraper Speed(r/min) | Feed Size(mm) | Temperature Adjustment Range(℃) | Heater Power(W) | Motor Power(W) | Diamensions L*W*H(mm) | Weight(kg) |

| XFDⅢ-0.5 | 0.5 | Ø45 | 0-2800 stepless | 15/30 | <0.25 | 50-95 | 300 | 120 | 440*320*750 | 30 |

| XFDⅢ-0.75 | 0.75 | Ø45 | 30 | |||||||

| XFDⅢ-1 | 1 | Ø55 | 440*320*840 | 35 | ||||||

| XFDⅢ-1.5 | 1.5 | Ø60 | 40 | |||||||

| XFDⅢ-3 | 3 | Ø70 | 440*320*890 | 50 | ||||||

| XFDⅢ-8 | 8 | Ø80 | 730*450*900 | 80 |

Successful Cases

Contact Us Now

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours. Rest assured that we won’t reveal your information to anyone.