Barite is a non-renewable resource and is widely used as a weighting agent for oil and natural gas drilling mud. Its consumption in the fields of barium chemicals and fillers is also increasing year by year. Barite is a very important raw material for amorphous minerals and has a wide range of industrial uses.

Why Recycle Barite?

Drilling mud weighting agent: in some oil wells and gas wells, drilling mud, and clay have a specific gravity of about 2.5, and water has a specific gravity of 1, so the specific gravity of the mud is low. Sometimes the mud weight cannot be balanced with the underground oil and gas pressure. Cause a blowout accident. In the case of high underground pressure, it is necessary to increase the specific gravity of the mud. Adding barite powder to the mud is an effective measure to increase the specific gravity of the mud. The density of barite is high. Nearly 90% of the barite produced in the world is used as drilling mud for oil and natural gas. The production of barite is closely related to the rise and fall of the oil and gas drilling industry.

Barite is mainly used in oil drilling mud, so oil price and barite demand are closely related. The current world oil prices remain high, and many countries are considering strengthening oil exploration and exploitation, which will inevitably lead to an increase in world demand for barite.

With the uncontrolled development of barite minerals, resulting in a serious shortage of barite resources, the price of barite powder has risen again and again. Many oil companies have been helpless and began to find barite recycling methods but with little effect. At present, some petroleum companies separate the barite from the waste liquid and then add it to the mixing station to mix with the newly added barite powder and mud. It is hoped that the barite can be recycled by this method. But different from the newly added barite, the recovered barite becomes very smooth under the action of friction during drilling and has an oil film attached to its surface, which follows the wall of the mixing tank under the action of the high-speed rotating mixer. It sinks to the bottom of the mixing tank, so it is not feasible to recycle the barite by stirring; in most cases, the barite is thrown away once it is used, which not only wastes resources but also has an impact on the environment. Therefore, barite recycling is necessary to save resources and reduce the impact on the environment.

Barite Recovery Case

Raw Material: Barite

Capacity: 15TPH

Country: Moroccan

Feed Size: <8mm

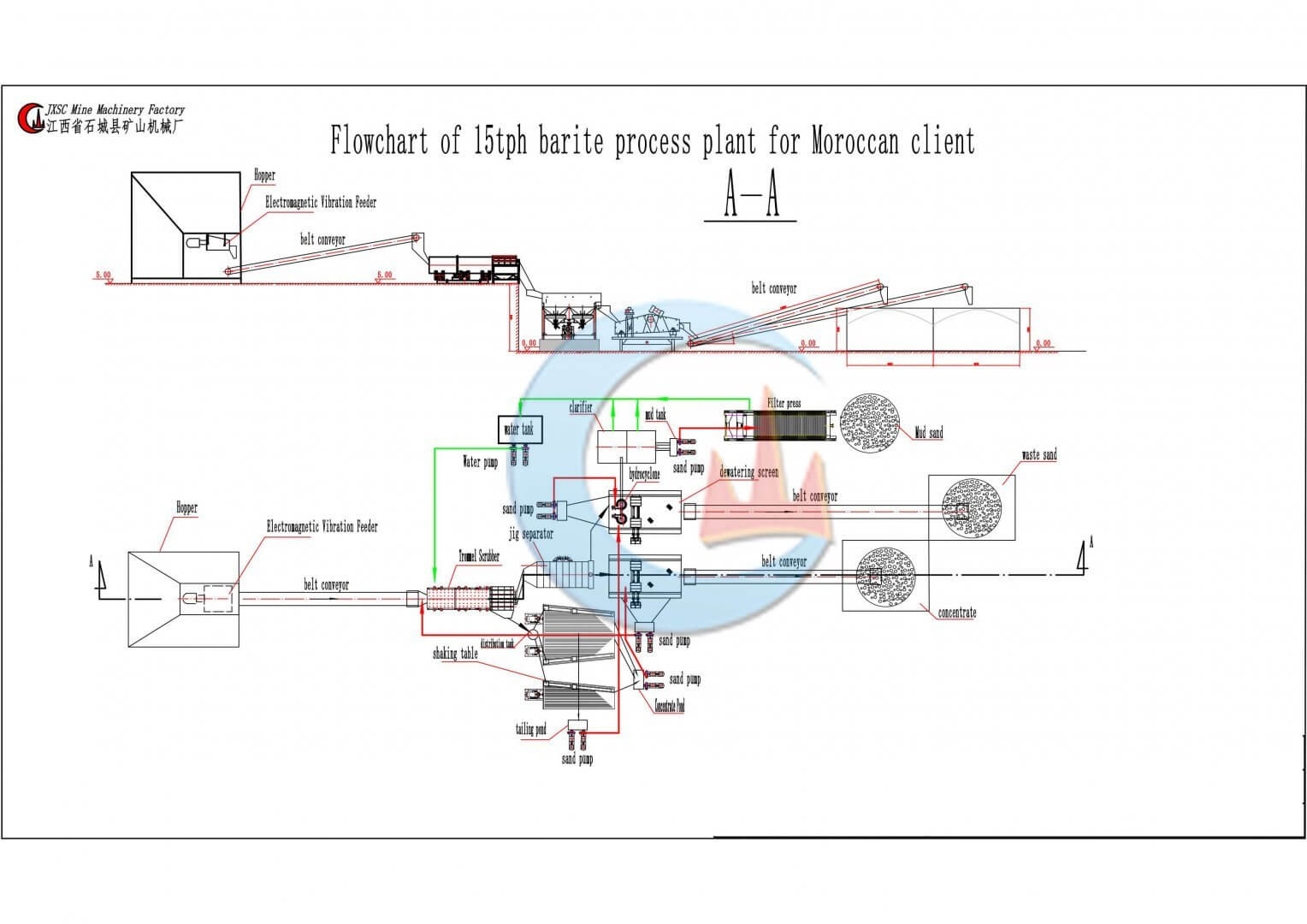

Flowchart

Equipment Used in The Above Process

- Hopper

- Electromagnetic Vibration Feeder

- Trommel Scrubber

- Shaking Tables

- Belt Conveyor

- Jig Separator

- Dewatering Screen

- Sand Pump

- Hydrocyclone

- Filter Press

- Water Pump

Barite Process Plant Explanation

- The size of Barite raw material is less than 8mm. Load the raw material into the hopper.

- Use the electromagnetic vibration feeder to feed the barite raw material to the belt conveyor until the trommel scrubber.

- The under-screen (0-2mm) slurry of trommel scrubber will go to a distribution tank and be fed to three sets of shaking tables.

- The over the screen (2-8mm) of the trommel scrubber will flow to the jig separator.

- The concentrate of shaking tables and jig separator will go to a concentrate pond and be pumped to a concentrate dewatering screen.

- The over concentrate dewatering screen materials are concentrates will be conveyed away by belt conveyor to concentrate zone.

- The under concentrate dewatering screen materials will be pumped back to the trommel scrubber by a sand pump.

- The tailings of shaking tables and jig separator will go to a tailing pond and be pumped to a tailing dewatering screen;

- The over tailing dewatering screen materials are waste sand will be conveyed away by belt conveyor to waste zone;

- The under tailing dewatering screen materials will be pumped to the hydro cyclone

- by a sand pump;

- The underflow of the hydro cyclone will flow to the tailing dewatering screen;

- The overflow of the hydro cyclone will flow to clarifiers;

- The mud outlet of clarifiers will go to a mud tank;

- The mud in the mud tank will be pumped to filter press by a filter press feed pump;

- The clean water from the filter press and clean water from the clarifier will be joined together and goes to rater tanks;

- The water in the water tanks will be pumped back to the trommel scrubber by a water pump.

The above barite process plant is not used crushing equipment because the raw material of this case is 0-8mm. For larger mining ore, there are 3 crushers recommend.

This is traditional equipment that is used by many users. It is very suitable to process barite. The main features are:

- The core component of the equipment is the jaw plate, which is driven by the motor to make the jaw plates squeeze each other to complete the crushing operation, so its discharge is more uniform.

- There are many kinds of materials processed by this equipment. In addition to barite, it can also crush materials of the same hardness, including marble, basalt, limestone, etc.

- As users have higher and higher requirements for this device, this device has been greatly improved in terms of function, performance, and structure, so its application rate is high.

It is a type of equipment with high technological content in the crushing field. It has the following advantages in the processing of barite:

- This device adopts a three-dimensional structure, so its floor space is gradually reduced, but the performance is more and more perfect, and the function is more and more, which can meet the actual application needs of users.

- Its production capacity is very large. In the process of developing this equipment, we attach great importance to the production capacity of the equipment, so its work efficiency will be higher and the output will reach the ideal application standard of the user.

- The crushing ratio is a physical quantity that measures whether the crushing equipment discharges uniformly. The larger the crushing ratio, the finer its discharge will be. Otherwise, the equipment’s operating state is very stable, and the crushing ratio advantage can be obtained. reflect.

Raymond Mill

Since barite is a non-metallic mineral, it is reasonable to process it with a Raymond mill. This equipment has the following advantages:

- The equipment can realize the self-adjustment function so that it can meet the different needs of users in terms of discharging, so its comprehensive utilization rate will be higher, and it will be able to play a greater practical value.

- Compared with the previous generation equipment, the safety factor of this equipment is very high. We have installed a protective circuit around the equipment motor so that it can play a decisive role in protecting the equipment and avoid greater damage to the equipment.

- In the process of equipment development, we have very strict quality control. We strive for perfection in every process and process, so its service life is longer, and it can be used for 8-10 years compared with similar equipment.

As a professional mining equipment supplier, JXSC Machine also manufactures other equipment to fit your needs, if you find a mining machine manufacturer in China, please contact us without hesitation.

LATEST PRODUCTS

Twin Screw Feeder

【Feeding Capacity】 10-160 t/h【Power】 2.2-…

Tubular Screw Conveyor

【Capacity】6-50 m3/h【Procesible Material】 …

Heavy Plate Feeder

Capacity: 100-240 m3/h Power: 15-45 kW Speed: 0…