Bauxite is an aluminum-containing mineral, and its main components include aluminum hydroxide, boehmite, diaspore, goethite, hematite, quartz, etc.

Bauxite is formed from the parent rock in hot and humid climates. Its color is grayish-white, brown-red, and yellowish-brown. Its appearance is similar to clay. It is an important raw material for producing metal aluminum and is widely used in national defense, aviation, automobiles, electrical appliances, chemicals, daily necessities, and other fields.

Bauxite Type

According to different mineral content, bauxite can be divided into four types: diaspore type, boehmite type, gibbsite type, and kaolinite type. According to the mineral composition, chemical composition, and basement lithology characteristics, bauxite can be divided into three types: laterite type, carbonate rock karst type, and Tikhvin type.

Laterite type

It is the cause of residual accumulation and is the product of in-situ lateralization of near-surface aluminosilicates. Gibbsite is the primary hydrous aluminum oxide, accounting for about 90% of the world’s total bauxite resources.

Carbonate rock karst type

It is also known as the Karst type, the main aluminum-containing minerals are boehmite and durasite, and the underlying rock is a carbonate rock, accounting for about 11.5% of the world’s total bauxite resources.

Tikhvin type

It is the product of weathering, transportation, and off-site deposition of pre-existing lateritic bauxite, which covers the aluminosilicate denudation surface. Still, it has no genetic relationship with the bedrock, accounting for about 0.5% of the total soil and mineral resources.

Bauxite Beneficiation

The process of separating bauxite concentrate from bauxite ore is a process of removing gangue minerals and harmful impurities, separating high-aluminum minerals and low-aluminum minerals, and obtaining concentrates with a high aluminum-silicon ratio.

The main beneficiation methods of bauxite include ore washing, flotation, magnetic separation, chemical beneficiation, etc.

Bauxite ore washing is the simplest and most effective method to increase the aluminum-silicon ratio of bauxite. Generally, the aluminum-silicon ore ratio can be increased by about two times through ore washing, which is more effective for separating loose ore. Ore washing is often combined with other sorting methods to form ore washing (screening & washing)-classification-hand selection process. Flotation can be used to separate diaspore and kaolinite, in an alkaline medium using oxidized paraffin wax soap and tall oil as collectors. Magnetic separation is used to separate iron-bearing minerals. Chemical beneficiation mainly includes roasting desalinization, which is based on the fact that the main silicon-containing minerals in the ore are hydrous aluminosilicates. After roasting, part of Si()z is transformed into amorphous silicon oxide particles that are easily soluble in alkali, which increases the aluminum-silicon ratio.

Generally speaking, the primary beneficiation process of bauxite will adopt different beneficiation processes according to different types of ore. For example, in the beneficiation process of gibbsite-kaolinite bauxite, mud and sand separation are often used first, coarse-grade ore grinding is followed by magnetic separation to remove iron, and ore slime is ground and then flotation. The flotation agent is prepared with oleic acid, tall oil, and engine oil at a ratio of 1:1:1.

The grade of bauxite flotation concentrate contains 49.65% alumina, the recovery rate is 45.3%, and the A1203/SiO2 is 12.3. The flotation method is more effective for the desalinization process of high-silicon bauxite. The aluminum mineral collectors include fatty acids and sulfonates, and the regulators include sodium hexametaphosphate, tannic acid, sodium pyrophosphate, soda, and Sodium carbonate. The beneficiation process of high-iron bauxite will adopt different iron removal methods according to iron minerals’ content, type, and distribution characteristics. The common ones are magnetic separation, roasting magnetic separation, and carrier flotation to remove iron.

The beneficiation methods of bauxite are complicated. In the beneficiation process, the corresponding beneficiation process should be selected according to the type and characteristics of the ore. At present, bauxite in China is mainly separated by flotation.

Bauxite Rough Processing and Equipment

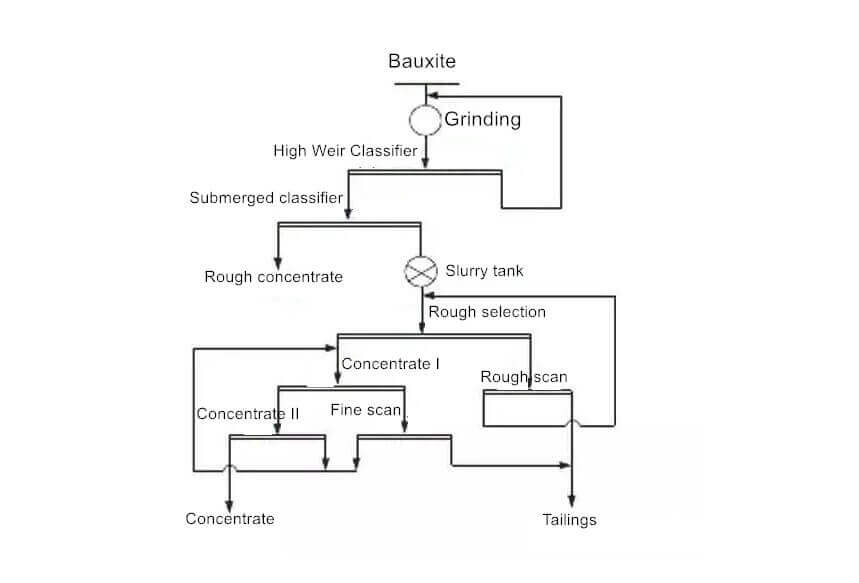

The difference in the raw ore and the manufacturer’s production process leads to some differences in the specific production steps. We have integrated some mineral processing production processes and roughly divided them into the following steps:

Feeding – crushing – grinding – grading – beneficiation

1. Feeding

Feeding is continuously and evenly feeding processed or unprocessed materials from specific equipment (hopper, storage bin, etc.) to the receiving equipment or transportation machinery.

Several standard feeders: trough feeders, disc feeders, pendulum feeders, vibrating feeders, and electromagnetic vibrating feeders.

2. Crushing

Crushing is the process of crushing a large piece of ore or ore to be processed, with the help of external force, to overcome the force between its internal molecules, so that the particle size of the ore is gradually reduced.

There are many crushers, such as jaw crushers, impact crushers, vertical impact crushers, hydraulic cone crushers, ring hammer crushers, hammer crushers, roll crushers, compound crushers, Cone Crusher, Double-stage Crusher, Gyratory Crusher, Mobile Crusher, etc.

3. Grinding

The crushed ore is further crushed into materials with smaller particle sizes.

A ball mill is a commonly used crushing equipment, divided into cement ball mill, tubular ball mill, ultra-fine lamination mill, conical ball mill, ceramic ball mill, intermittent ball mill, overflow ball mill, lattice ball mill, wind discharge ball mill, double warehouse ball mill, energy-saving ball mill, and other types.

4. Grading

According to the principle that solid particles have different settling velocities in the medium due to different particle sizes, the particle group is divided into two or more particle size levels.

Classification equipment includes two types: screening and grading equipment, standard high-frequency vibrating fine screens, screening machines, electromagnetic high-frequency vibrating screens, hydraulic grading equipment, common pyramid pools, inclined plate (inclined tube) grading equipment, and hydraulic Cyclone. Classification equipment often forms a closed-circuit process with a ball mill.

5. Mineral Dressing

The main beneficiation methods of bauxite are ore washing, flotation, magnetic separation, chemical, and physical beneficiation, etc. These methods are usually used in combination.

Ore washing: Using the principle of gravity physics, the aluminum-silicon ratio of loose aluminum ore is more than doubled.

Commonly used equipment: Hydraulic washing screen, cylindrical washing machine, trough machine, vibrating screen machine, etc.

Flotation: It is a standard method in various beneficiation processes. It is mainly used to separate diaspore and kaolinite, and alkaline substances are added to the flotation machine as a medium.

Commonly used equipment: Mechanical stirring flotation machine, jet swirl flotation machine, flotation column, flotation bed, etc.

Magnetic separation: A magnetic separator separates iron impurities in aluminum ore.

Commonly used equipment: Permanent magnet magnetic separator, electromagnetic magnetic separator, etc.

Chemical and physical methods: Mainly roasting desiliconization, this method is mainly based on hydrous aluminum band silicate in minerals, as a result, part of the silica can be converted into tailings that are amorphous and easy to-enter alkaline silica particles, So as to achieve the purpose of increasing the ratio of aluminum to silicon.

Common roasting equipment: Shaft furnace, fluidized fluid bed furnace, rotary kiln, etc.

Bauxite concentrate can be obtained through the above processing process, and the bauxite concentrate is used to produce alumina, and the obtained alumina can be made into alumina.

LATEST PRODUCTS

Twin Screw Feeder

【Feeding Capacity】 10-160 t/h【Power】 2.2-…

Tubular Screw Conveyor

【Capacity】6-50 m3/h【Procesible Material】 …

Heavy Plate Feeder

Capacity: 100-240 m3/h Power: 15-45 kW Speed: 0…