- Pre-operational checks

- Unit operation: Warm-up, Power-on, Starting, Running, Emergency stop, Normal shutdown

- After running

- Operating records

- Notes

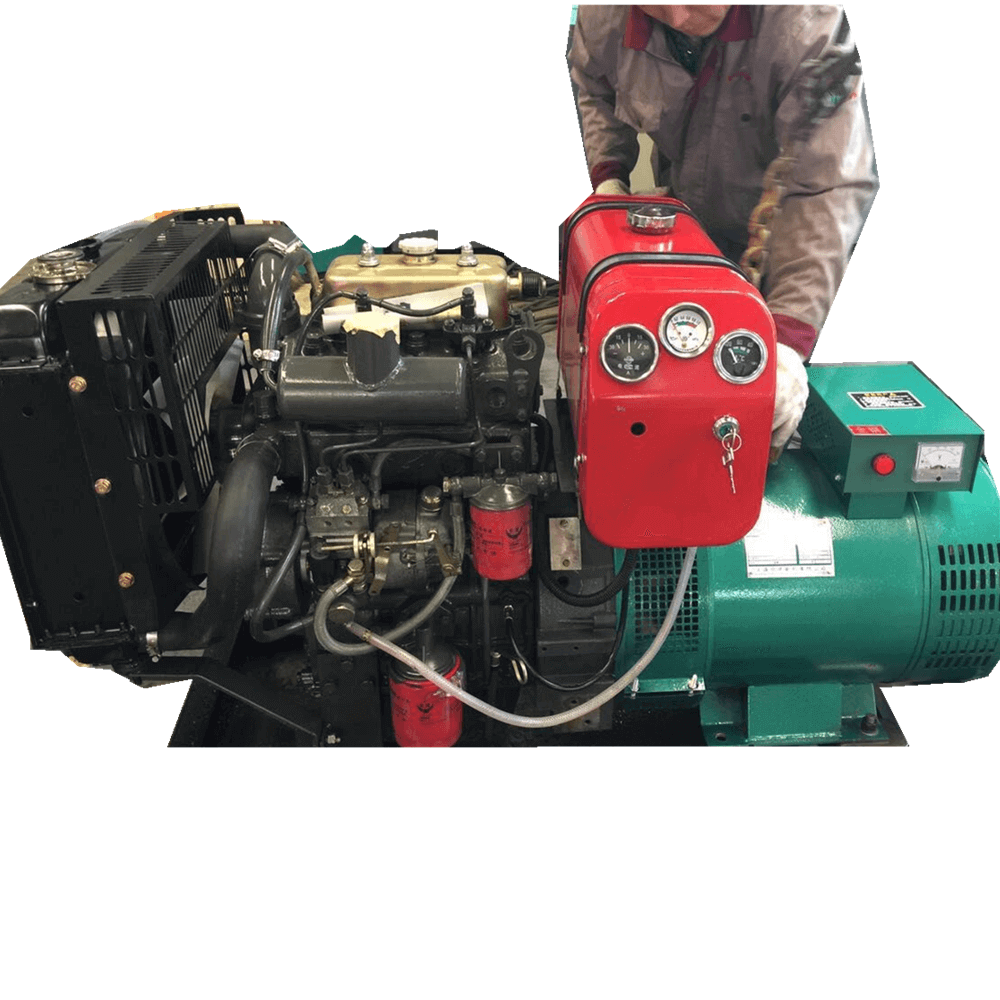

Diesel Generator Set Running Opearation Manual

Running Operation Manual

1. Pre-operational checks

Diesel generator sets installed, can be put into power generation run, should be at least the following items to check before each boot:

- Unit surface and is surrounded by things debris hinder

- Into the engine room, the exhaust air channel is smooth

- Tank cooling liquid

- Air filter to indicate normal

- The oil level is within the normal range

- The fuel valve is turned on, the fuel is the normal supply of the engine

- Battery cables are connected correctly

- The power generation load device is ready, and the generator with direct load, before the start must be breaking the air switch.Operators to establish a good operating (maintenance) program, the basic guarantee unit long-term trouble-free operation.

2. Unit Operation

1. Warm-up

Preheater unit before the start of the personnel according to the ambient temperature determine whether the unit into the warm-up operation, with the warm-up button on the control panel to control the engine to start the heater to work in order to achieve the purpose of warm-up.

2. Power-on

Screen key switch will control the fight from the “OFF” to “ON” position to observe the instrument background to the panel lights, said to control the power-unit of fuel in the open state, with control of the electronic speed controller or fuel injection Unit also in working condition.

3. Starting

Part of the unit control panel with idle / full-speed change-over switch, the user can be based on actual need, select whether to start idling or at full speed, one-time activation. Usually, idle running time should not be more than five minutes, the unit should not run in the idle state for a long time. Press the start button, the duration of not more than 30 seconds, the engine-driven to start the motor started, once started, you can release the start button, the unit entered the running state.

Recommendation: To extend the life of the start battery and starter motor, the time you start the unit time control of 5 to 10 seconds is appropriate. If a start is unsuccessful, you can pause the appropriate time for the second start of the program.

With the start (or communication) instrument control panel, preheating unit to start the cycle, and the number of stars by the program control (the user of the program can be set to change). The specific use is detailed in the random instructions.

When the unit control panel failure, its maintenance to boot.

Not forced to start the engine by controlling the screen, its consequences will not receive warranty service.

4. Running

Unit into the run at full speed, generator voltage, frequency of normal and stable, the operator can generate electricity on the air opening and closing.

Unit in operation, the operator should also frequently observe understanding of plant operation if the normal position, the control panel with or without pre-alarm indication, fuel tank fuel bit such as operating parameters, and regularly recorded on the unit operating parameters (see table)

Running record table

| Time | Engine parameters | Generator parameters | Fault | Operator | Remarks | |||||

| Boot Time | Stop Time | Cumulative Hours | Hydraulic Pa | temperature ℃ | Volta ge V | Current A | Frequency Hz | |||

5. Emergency stop

Once the operator found the unit to a serious malfunction or failure of distribution, you can press the control panel emergency stop button, immediately shut down the unit. No special circumstances occur, do not recommend users to freely through the emergency stop button to stop operation of the unit.

6. Normal shutdown

Before the unit normal shutdown, the load separation (generating open space breaking), then the unit-load operation after a certain time (3 to 5 minutes) to allow the unit to be fully cooled after shutdown. (Cooling run) Do not idle under.

Part of the unit to install a stop valve, of the control panel key switch the unit to stop operation is not valid. The correct operation of the shutdown, must control the power-on screen, press the stop button to make the unit stop running.

3. After running

Unit after the shutdown, there is a need for the following tasks:

- Check the unit with or without the “leakage” phenomenon (oil, fuel, coolant)

- Close the fuel valve

- Shut down the engine room into the ventilation facilities

- Turn off the generator output to open space

- Close the control panel power key switch, remove the key for safekeeping

- Downtime or unit maintenance, demolition will start the unit to the battery negative cable, fuel, and coolant, if necessary, should be exhausted.

4. Operating records

The units are each run, the user must do a good job running records, running record form has diversity. The basic content should be included: the running time, the unit total running time, running the engine oil pressure gauge, thermometer readings, power generation, voltage, frequency, maximum power (current) record, the unit operation, the unit with or without failure alarm/shutdown and so on.

Correct and complete the operation (maintenance) record, the user can correct and perfect after-sale (warranty) service.

5. Notes

When the engine temperature is low, the idle running time should be extended; when the unit warm-up. Does not allow units to run at idle for a long time, does not allow continuous operation of units in the case of no-load or small load, so running will cause serious carbon deposition and leakage of engine turbochargers and exhaust systems.

Do not allow unit overload long run, otherwise, it will lead to unit failure, reduce the unit life. Disassembly is prohibited in the unit operation, the replacement unit on parts. Add coolant to be used when the original cooling system coolant, open the filler cap, note whether there is high temperature, to prevent steam or hot coolant spray wounding.

Emissions from high-temperature lubricants should be to prevent burns.

Must use the fuel to meet national standards, otherwise, it will cause the failure of the engine fuel injector.

Engine with a turbocharger does not recommend the unit to withstand more than 50% of sudden load Otherwise, it will cause a larger unit of the stall, it is recommended that users of large electrical equipment, take blood pressure, frequency, and other methods to control its start to slow start when the unit greater impact.

Standby unit or long-running units, it is recommended that at least a month to let the unit run to operating temperature at least once a year to let the unit with a full load run about four hours, which can burn the carbon deposits in the engine exhaust system.

The manual control unit must ensure synchronization (with the same frequency with the phase sequence, with the phase with the voltage) before closing, the downtime must sub-gate downtime, and in the use of the unit must be on duty to prevent the stand-alone downtime.

LATEST PRODUCTS

Heavy Plate Feeder

Capacity: 100-240 m3/h Power: 15-45 kW Speed: 0…

Plate Magnetic Separator

【Capacity】8-35 t/h 【Power】1.5-3 kW 【Applic…

Slurry Magnetic Separator

【Capacity】10-100 m3/h 【Feeding Material Densi…