The high gradient magnetic separator (HGMS) is a strong magnetic separator for the screening of weakly magnetic minerals. It is a new type of strong magnetic separator developed on the basis of a general magnetic separator machine.

The high gradient magnetic separator equipment is suitable for:

Separation of weak magnetic minerals, such as hematite, limonite, siderite, ilmenite, chromite, wolframite, tantalum-niobium ores, red mud and so on;

Iron removal and purification of coal, non-metallic minerals, building materials, such as quartz, feldspar, nepheline, fluorite, sillimanite, spodumene, kaolin, etc;

It also used for wet magnetic separation of magnetite, pyrrhotite, roasting ore, ilmenite and other materials with a particle size of 3mm or less.

- Dry permanent magnet high gradient magnetic separator

The machine has two permanent magnets inside and outside, and the sorting gap between the two magnetic systems can be adjusted. During operation, the dry material dispersed by the impeller follows the sorting space of the impeller wind force magnetic separator, and the non-magnetic material is thrown out with its own trajectory, and the magnetic material is adsorbed on the steel mesh medium, and leaves the sorting space as the medium rotates. Falling off under the vibration of the magnetic medium. Mechanical vibration can improve the material sorting accuracy, and the barrel can avoid the mechanical inclusion of materials. This machine is used for the removal of iron from potassium feldspar. The feed particle size was -0.045mm, and the content of Fe2O3 decreased from 0.27% to 0.18% after sorting. - Vibration high gradient magnetic separator

The vibration feeding to the mine and the vibration discharging method maintain the fluidity of the fine dry powder material, and the weak magnetic material is captured by the induced magnetic field in the medium box and discharged at the upper portion, and the dry continuous sorting of the fine particle material can be realized. In the iron removal test of coal-series kaolin in Anhui, the Fe2O3 content of the raw material decreased from 0.73% to 0.5%, which is equivalent to the wet selection result. - Periodic high gradient magnetic separator

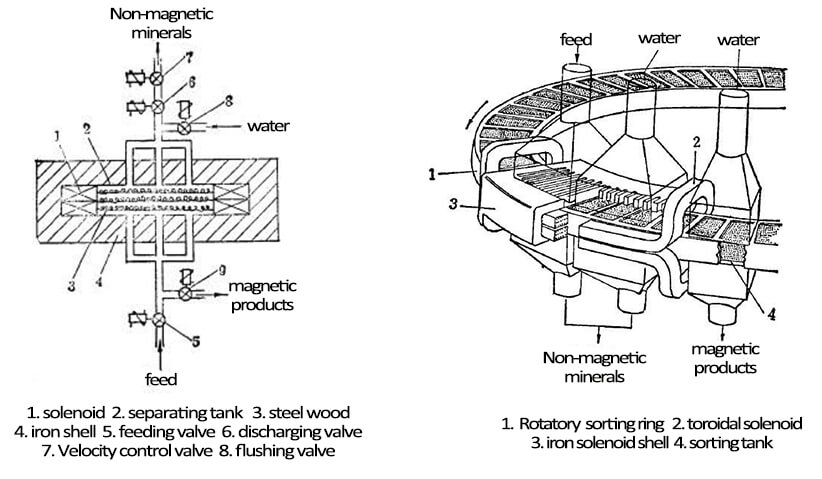

The periodic high gradient magnetic separator works in three stages, feeding, washing and flushing. The slurry (concentration is generally about 30%) enters the sorting zone slowly, the magnetic particles are adsorbed on the steel wool, and the remaining slurry is discharged through the upper discharge valve.

Stop the feed, open the flush valve, and rinse off the non-magnetic particles trapped on the steel wool. Then cut off the DC power supply, gradually demagnetize the steel wool, then open the upper flushing water valve, feed the high-pressure flushing water, rinse the magnetic particles adsorbed on the steel wool, and discharge it from the lower discharge valve.

Completing one of the above processes is called a work cycle, a circle about takes 15 minutes, the HGMS machine can be carried out automatically according to the procedure.

You may interest in: How Many Types of Magnetic Separators?

The HGMS is mainly composed of a pulsating mechanism, an excitation coil, an iron yoke and a rotating ring.

It is divided into dry type and wet type magnetic machine. The weak magnetic ore mainly has limonite, hematite, manganese ore, and symbiotic ore (multiple ores coexisting). These weak magnetic ores are mainly composed of ferric oxide, if you want to extract ferric oxide, you need to use high-strength magnetic equipment. Our company has developed a high-strength magnetic concentrator for this difficult mine.

There are many weak magnetic ores that are bulk and need to be crushed first, crushing, grinding then magnetic separation. The general process flow is ore analysis, jaw crusher, screen, roller crusher, ball mill, magnetic separation.

The HGMS adopts a rotating ring vertical rotation and recoil concentrate, and a high-frequency vibration mechanism.

It fundamentally solves the worldwide technical problem that the magnetic material of the flat ring strong magnetic separator and the flat ring high gradient magnetic separator are easy to block.

Under the action of the water flow to the mine spout, the ore particles are loosely fed into the feed area of the tank. In the magnetic field, the magnetic ore particles are magnetically aggregated and moved toward the magnetic poles and adsorbed on the cylinder. When the magnetic ore particles rotate with the cylinder, the non-magnetic minerals such as gangues entrained in the magnetic clusters fall off during the turning, and the magnetic cluster finally attracted to the surface of the cylinder is the concentrate.

The concentrate goes to the weakest point of the magnetic system at the edge of the magnetic system with the cylinder, and is discharged into the concentrate tank under the action of the flushing water sprayed from the unloading water pipe. Non-magnetic or weakly magnetic minerals are left in the slurry with the slurry exiting the trough, which is the tailings.

HGMS has the advantages of large enrichment ratios, strong adaptability to feedstock concentration, concentration and fluctuation, reliable work, convenient operation and maintenance.

The magnetic system of the high gradient magnetic separator is made of high-quality ferrite material or composited with rare earth magnetic steel. The average magnetic induction intensity of the magnetic roller surface is 100-600 mT. According to the needs of users, it can provide magnetic separation of many different surface strengths such as downstream, semi-reverse flow and counterflow.

During the operation of the high gradient magnetic separator, for each group of magnetic media, the direction of the rinse concentrate is opposite to that of the ore supply, and the coarse particles can be washed out without passing through the magnetic medium stack, thereby effectively preventing the magnetic medium. Blockage; set the high-frequency vibration mechanism of the slurry to drive the slurry to generate pulsating fluid force.

Under the action of pulsating fluid force, the ore particles in the slurry are always in a loose state, which can improve the quality of the magnetic concentrate; the flat ring high gradient magnetic separator has strict requirements on the ore size, unique magnetic structure and optimized combination of magnetic The medium makes the magnetic separator upper limit of 2.0 mm, which simplifies the on-site grading operation and has wider adaptability. The multi-gradient medium technology and the liquid level stability control device improve the iron concentrate grade and recovery rate; The ring speed and the vibration frequency of the high-frequency vibration box are steplessly adjusted by the inverter; compared with the domestic similar products, its unique design effectively solves the “stepping” phenomenon of the rotating ring.

- Ferrous metal: recovery of martite, hematite, limonite, siderite, chromite, ilmenite, manganese ore, etc;

- Non-ferrous metals: recovery of fine-grained black tungsten ore in tungsten-containing quartz veins; separation of pyrrhotite in cassiterite polymetallic sulfide ore; separation of scheelite from wolframite, garnet and other minerals, etc;

- Rare metal: recovery of tantalum niobite, zinnwaldite, monazite, etc.

- Non-metal: glass-ceramic industry raw materials quartz, feldspar, kaolin purification, high-temperature refractory sillimanite, andalusite, kyanite de-ironing and removal of hornblende, mica, tourmaline, garnet, etc. Impurities, etc.

- Others: weak magnetic tailings recovery; alumina plant hematite mud selection; wastewater treatment of steel plants, power plants; cleaning of chemical raw materials contaminated by catalysts.

You may interest in:

1. HGMS uses for kaolin clay beneficiation process

2. Strong, medium, and weak magnetic minerals

The brand has Slon high gradient magnetic separator, Flsmidth, Metso, etc.

JXSC has always been developing the magnetic separation technique, and bring magnetic separation machines for the mining industry. Contact us to get the price and specification info.