Slag is also called molten slag. The melt that floats on the surface of liquid substances such as metals during the pyrometallurgical process is composed mainly of oxides (silicon dioxide, aluminum oxide, calcium oxide, magnesium oxide), and often contains sulfides and a small amount of metal.

Slag Introduction

The composition of the slag is adjusted by adding an appropriate amount of flux (lime, quartzite, fluorite, etc.). In the smelting process, by controlling the composition and properties of the slag, the products of gangue and oxidized impurities can be smoothly separated from the molten metal or sulfur, the harmful impurities in the metal are removed, and the non-metallic inclusions in the liquid metal are not directly affected. Furnace gas is polluted, and useful metal oxides are enriched; it is also a resistance heating element in electric furnace smelting. Slag plays a decisive role in ensuring the smooth progress of smelting operations, the quality of smelted products, and the metal recovery rate.

Slag Classification

According to different metallurgical processes, slag can be divided into smelting slag and refined slag. Using ore (including man-made rich ore or concentrate, etc.) as raw materials for reduction smelting or oxidation smelting, the slag formed while obtaining coarse metal or matte is called smelting slag. The slag produced by refining crude metal (smelting steel with pig iron, refining copper from blister copper, etc.) is called refined slag. The main function of these two types of slag is to remove the useless or harmful substances in the raw materials from the metal products. There is another type of slag whose main function is to enrich certain useful substances contained in the raw materials in order to facilitate recycling them in the next process. This is called enriched slags, such as high titanium slag obtained by reduction smelting of titanium concentrate and converting Vanadium slag and niobium slag obtained from pig iron containing vanadium and niobium are used as raw materials for extracting titanium, vanadium, and niobium, respectively. There is also a type of so-called “synthetic slag”, which is pre-prepared with various raw materials according to the metallurgical role of the slag, such as electroslag remelting slag, mold slag used for ingot casting or continuous steel casting, and molten steel. Slag washing with slag, etc.

Metal Slag Recycling

Valuable metals enter the slag due to mechanical loss, chemical loss, and physical loss. When it is economically uneconomical to recover these metals from the slag, the slag can be discarded for other purposes. For example, copper smelting waste slag contains Cu 0.2-0.4%, and ferrovanadium smelting waste slag contains V2O50.2-0.3%. Reasonable selection of the composition of the slag according to the physical and chemical properties plays an important role in reducing the content of valuable metals in the waste slag. The non-ferrous metal refining slag contains very high-value metals and is generally returned to the previous process of process. Among the raw materials for metal refining, in addition to the main metal, there are other metals with recycling value. Generally speaking, whether the metal has recycling value depends on the use-value of the metal, the cost of recycling, and the price of the commodity. It is often recovered from the slag or smoke produced in the process of smelting the main metal. Among the smelting raw materials of non-ferrous heavy metals, most of the valuable metals are precious metals and rare metals, which have a high recovery value.

Slag Recycling Plant

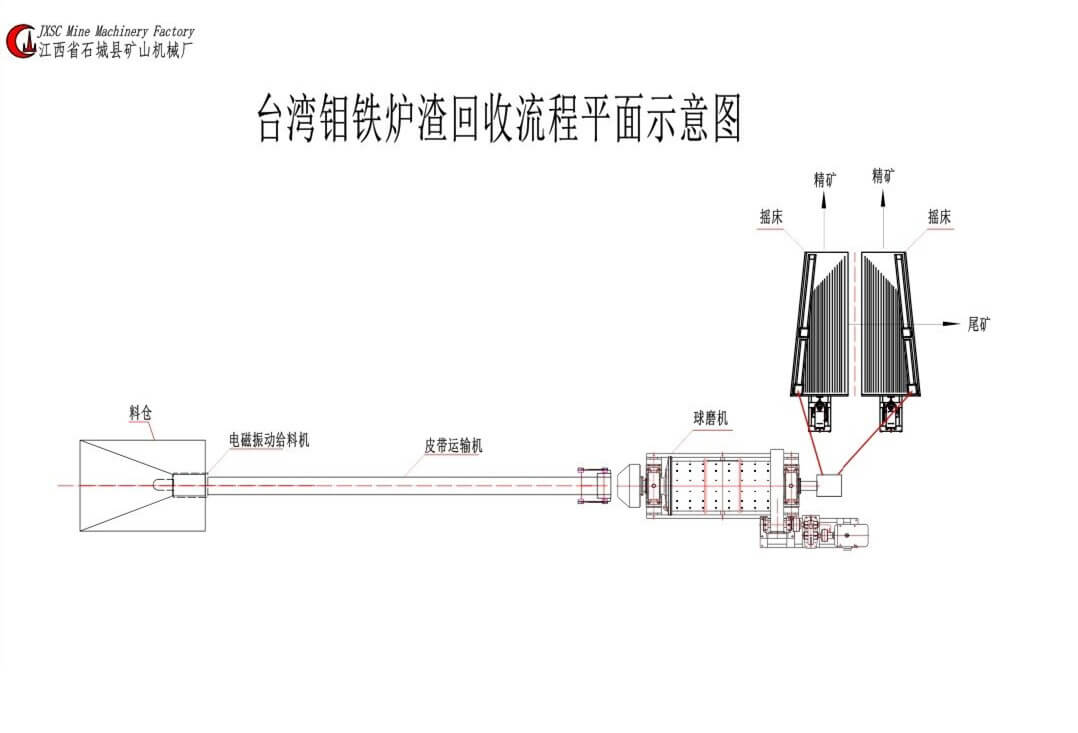

Molybdenum Iron Slag Recovery Process Plant

This Flowchart is designed for Processing 1-2TPH Molybdenum Iron Slag for recovery iron and Molybdenum metals from slag. We provided a complete set of plant machines for our Taiwan customers. Including feeding hopper, electromagnetic vibration feeder, belt conveyor, ball mill, steel balls, shaking table, etc.,

The vibration feeder is for feeding material smoothly and evenly to the ball mill, so as can grind high effectively. Ball mill is for grinding slag (0-20mm) to 0-1mm or smaller size depending on customer requirement. Then output small fine powder go to shaking table for recovery the metals from slag. The shaking table has an extremely high recovery ratio for recovery heavy metals from slag. Then will get metal concentrate from the shaking table.

The slag is a very hard material and contains a lot of oil. So has a high requirement for the grinding machine and belt conveyor, the belt conveyor needs to be Nylon material, oil, and solvent resistant. Ball Mill needs more thick lining plates for wear-resistant. some customers also will use rod mills to grind slag.

The flowchart can be customized design according to slag material condition, the requirement for the final product, and process capacity.

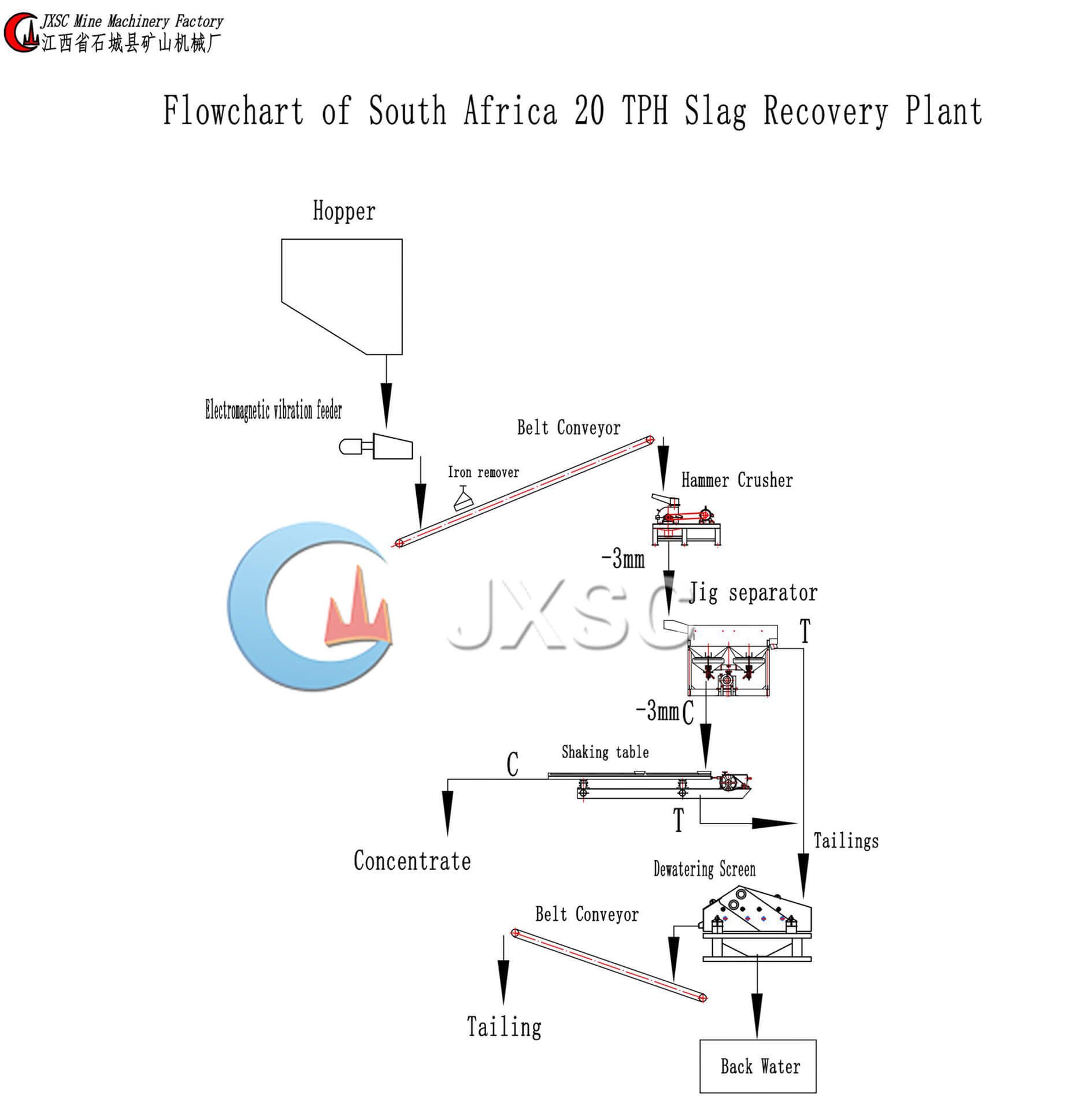

Ferrochrome Slag Recovery Process Plant

This processing plant is for the slag to recovery the Ferrochrome. The process is as follows.

The wheel loader or excavator feeds the raw slag to the hopper. There is an electromagnetic vibration feeder under the hopper, which can feed the material to the belt conveyor more evenly. The client requires iron removal equipment to remove the big Fe slag first. The material will be fed into hammer crusher by belt conveyor, using hammer crusher for crushing the big slag into fine particles 3mm. The output size can be adjusted based on your requirement. The output from the hammer crusher goes to the jig separator for catching concentrates first. The under-screen from the jig separator goes to the shaking table for separation again, to improve the grade. The tailings from the jig separator and shaking table will go to the dewatering screen for dewatering water.

The required processing capacity for this flowsheet is 20 tons per hour input feeding capacity. while any capacity is ok. Different mine situations and different requirements, the solution will be different.

Referring to recycling the slag, we also can design metal slag recycling plants including lead, iron, steel, nickel, aluminum, copper, and so on according to your actually slag recycling goals. If you need to recycle the metal from the slag, please contact us to get the free flow design.

LATEST PRODUCTS

Tubular Screw Conveyor

【Capacity】6-50 m3/h【Procesible Material】 …

Heavy Plate Feeder

Capacity: 100-240 m3/h Power: 15-45 kW Speed: 0…

Plate Magnetic Separator

【Capacity】8-35 t/h 【Power】1.5-3 kW 【Applic…