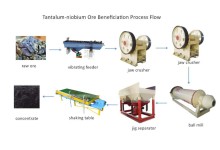

Tantalum & Niobium Mineral Processing in The World

Tantalum-niobium ore beneficiation generally uses gravity separation. First, discard most of the gangue minerals to obtain low-grade mixed coarse concentrates. The mineral composition of the coarse concentrates entering the beneficiation operation is complex and generally contains a variety of useful minerals. It is difficult to sort. Usually, a variety of beneficiation methods such as gravity … Continue reading Tantalum & Niobium Mineral Processing in The World