What is the cement ball mill?

The cement ball mill is mainly used for grinding the finished products and raw materials of cement plants, and is also suitable for grinding various ore and other grindable materials in industrial and mining enterprises such as metallurgy, chemical industry, and electric power.

Cement grinding is the last process of cement production, it is to mix cement clinker and a small amount of gypsum, and then grind the mixture to a certain fineness, that is cement.

You may also interest in the ball mill product price, lime ball mill, quartz ball mill.

【Cement grinder types】

Cement ball mills can be divided according to discharge method: grate ball mills and overflow mills, and can be divided into wet mills and dry mills according to their processing conditions.

【Cement mill structure】

Ball mill is mainly composed of feeding part, supporting frame, rotary part, discharge, transmission, lubricant and cooling part.

How does ball mill work?

The main working part of the cement grinding mill is a rotary cylinder mounted on two large bearings and placed horizontally. The cylinder is divided into several chambers by a partition plate, and a certain shape and size of grinding bodies are installed in each chamber. The grinding bodies are generally steel balls, steel forgings, steel rods, pebbles, gravel, and porcelain balls. In order to prevent the cylinder from being worn, a liner is installed on the inner wall of the cylinder.

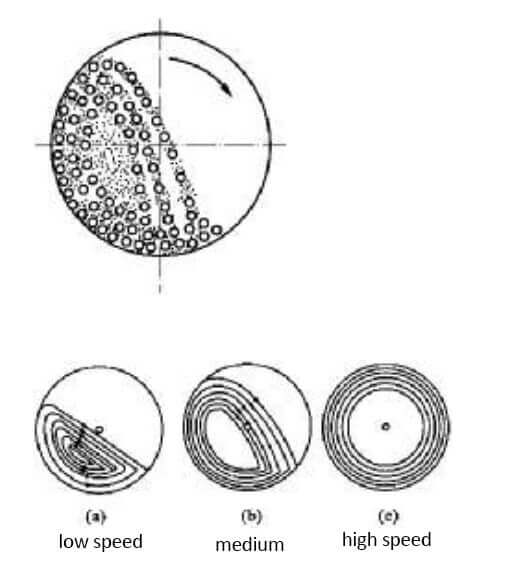

When the cement grinding machine rotates, the grinding media adheres to the lining surface of the inner wall of the cylinder under the action of centrifugal force and frictional force with the lining surface of the inner surface of the cylinder, and rotates with the cylinder and is brought to a certain height. Under the action of gravity, it falls freely. When falling, the grinding media acts as a projectile and impacts the material at the bottom to crush the material. The cyclic motion of the abrasive body rising and falling is repeated. In addition, during the rotation of the mill, the grinding body also slides and rolls, so the grinding action occurs between the grinding body, the liner and the material, making the material fine. As new materials are continuously fed at the feed end, there is a material level difference between the feed and discharge end materials to force the material to flow, and the axial thrust of the impact material when the grinding body falls also breaks the material flow. Air movement also helps material flow. Therefore, although the mill barrel is placed horizontally, the material can slowly flow from the feed end to the discharge end to complete the grinding operation.

【Ball mill liner】

The liner of cement dry-type ball mill can be divided into ceramic, granite, rubber, high manganese, magnetic liner and other materials. The function of liner is mainly to protect the cylinder from the direct impact of materials and steel balls and extend the service life. At the same time, the liner plate can also adjust the running track of materials. Generally, the head grinding bin is equipped with hard liner plate, which can enhance the impact force of materials and accelerate grinding. The liner plate of the fine grinding bin is corrugated liner plate or flat liner plate, which can enhance the grinding effect of materials.

【Ball mill grinding medium】

The grinding medium of cement dry ball mill includes steel ball, steel rod, steel pipe, stone, porcelain ball, etc. the steel ball is divided into cast iron, bearing steel, carbon steel and other materials, and the diameter of steel ball varies from 15mm to 125mm. The steel bar is short cylindrical or conical, which has line surface contact with the material and strong grinding effect.

【Cement ball mill advantages】

1. It has strong adaptability to materials, continuous production and large processing capacity. The equipment has stable performance, is convenient for large-scale production, and meets the needs of large-scale production of modern enterprises.

2. The crushing ratio is large, the feeding size can reach 50 mm, the discharging particle size can be controlled, and the particle quality is good.

3. Cement dry-type ball mill is mainly used for grinding raw materials and clinker (finished products and raw materials) in cement plant, and also for grinding various ores and other grindable materials in metallurgy, chemical industry, electric power and other industrial and mining enterprises. It can be used for open flow grinding and circular flow grinding composed of powder concentrator.

4. The structure is reasonable, firm and can be operated under negative pressure. Cement dry ball mill has good sealing performance, environmental protection, simple maintenance, safe and reliable operation.

【Disadvantages】

But at present, the overall efficiency of cement dry-type ball mill grinding is low and energy consumption is large. Although the rolling bearing transmission mode is used now, the cement mill process is still the most power consuming part of the enterprise. Moreover, the cement dry-type ball mill is generally medium and long grinding, with large investment and high cost.

Ball mill cement grinding circuit

The application of ball mill in cement industry dates back more than 100 years. The ball mill for cement grinding plant is mainly of high fineness, dry grinding method, and the process is mainly of open circuit process and closed circuit process. The equipment of ball mill used in cement plant includes vertical cement mill, roller press and ball mill, etc.

The cement ball mill in cement plant is usually divided into 2-4 silos, the most representative of which are the “new type of high fineness cement ball mill” and “open flow high fineness cement ball mill”.

There are three cement processing circuits.

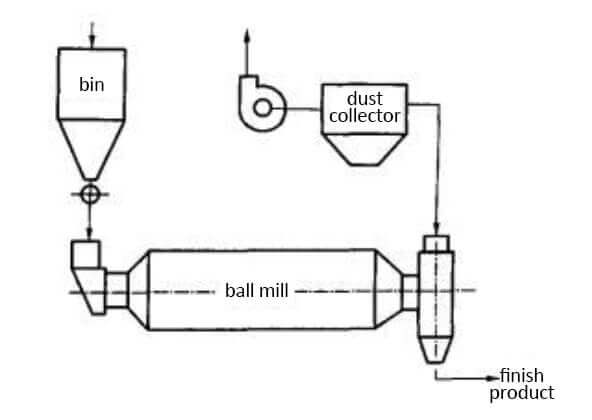

1. Open circuit grinding

The ball mill in the cement plant for open circuit grinding consists of grinding bin, dust collector and ball mill.

Advantages: the cement plant process is the simplest, with less investment and simple operation and maintenance.

Disadvantages: serious over grinding in the mill, low efficiency, difficulty in fineness adjustment of finished products, high power consumption.

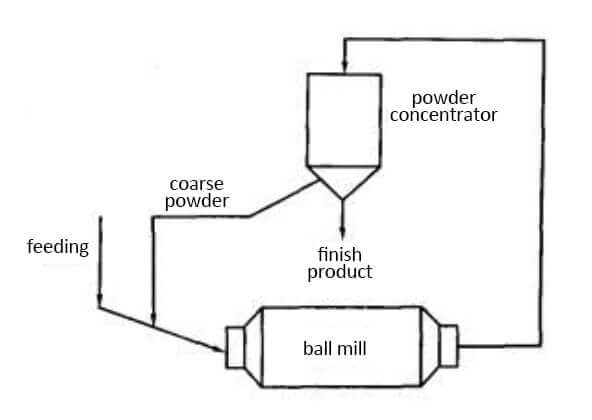

2. Closed circuit grinding

Closed-circuit grinding is widely used in cement mills all over the world. Cement grinding unit is widely used in the United States, Germany, France, Japan and other developed countries. For example, 95% of cement in Japan comes from closed-circuit grinding.

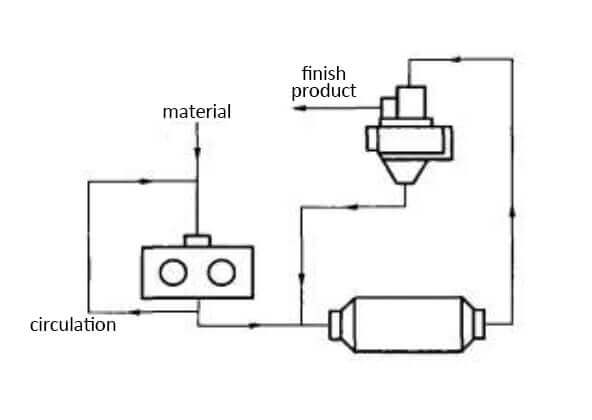

The cement plant machinery of closed-circuit grinding consists of feeding system, finished product bin, powder concentrator and dust collection equipment. The process is relatively complete.

The disadvantages are a large investment, many equipment and complex operation.

3. Pre grinding

This kind of cement clinker grinding plant means that the cement raw materials are treated with other grinding equipment before entering the ball mill.

According to many years of practical production experience, JXSC summarizes that cement producers with a production capacity of fewer than 30 tons per hour are suitable for open circuit grinding, and closed-circuit grinding for large-scale production can be more economical.

【Matters need attention】

1. Cement has corrosion, which affects the service life of steel ball and increases the production cost.

2. Different wear-resistant microelements in different materials of wear-resistant steel balls will be damaged, which will cause poor wear-resistant effect and serious waste of clinker grinding mill.

3. During cement grinding, the material temperature may be higher than 100 ℃, leading to dehydration of most gypsum or complete dehydration, causing coagulate of cement, which requires corresponding cooling measures, including mill ventilation, cylinder water cooling, etc.

4. After each clinker grinding, clean the cement grinding system, so as to avoid inconvenience to the next start-up due to slag material deposition.

【Cement mill price】

Cement ball mill specially used for grinding cement clinker and other materials in building materials, cement production, metallurgical ceramics, electric power and petrochemical industry. JXSC can design and manufacture special cement ball mill equipment according to the output and fineness requirements of users. Contact us for machine selection and a price quotation.

LATEST PRODUCTS

Twin Screw Feeder

【Feeding Capacity】 10-160 t/h【Power】 2.2-…

Tubular Screw Conveyor

【Capacity】6-50 m3/h【Procesible Material】 …

Heavy Plate Feeder

Capacity: 100-240 m3/h Power: 15-45 kW Speed: 0…