Rock crushing equipment is widely used and plays a key role in the mining and construction industries. For the economical and efficient crushing procedure, choosing the most suitable rock crusher machine is vital for your business. Jaw crusher and impact crusher are the two common crushers applied, do you know what is the difference between the jaw crusher and impact crusher? Before placing an order, let’s make a comparison of these two crushing machines.

1. Application

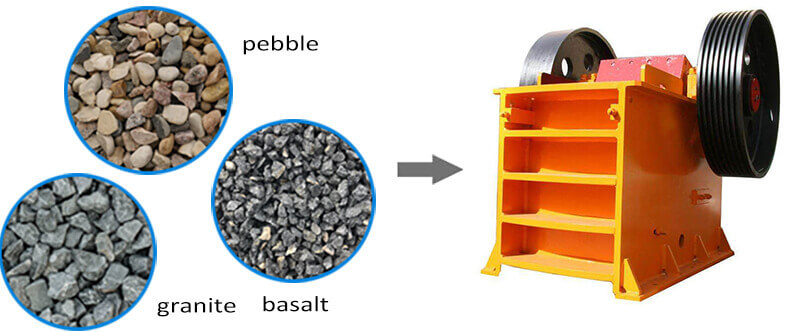

1. Jaw crushers are mainly used as primary crushers, it can crush hard material, such as granite, basalt.

2. Impact crusher is usually used as a medium-fine hardness crusher, such as limestone, concrete, it has good crushing efficiency of some brittle material. It mainly crushes the small material discharge from the jaw crusher.

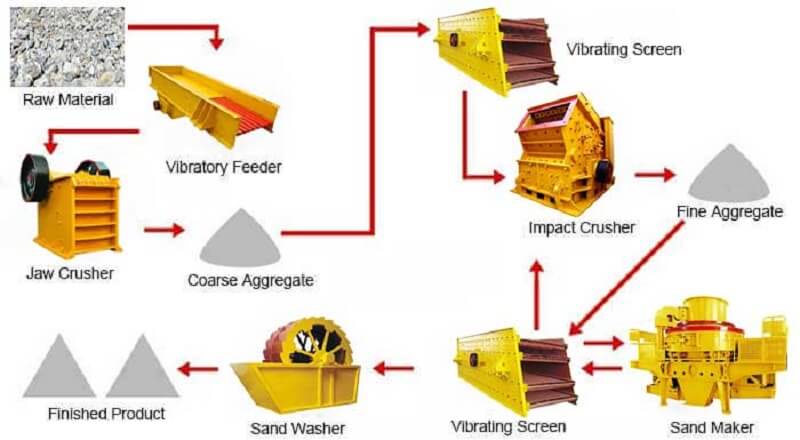

In general, the jaw crushers are placed before the impact crusher.

2. Capacity

1. Jaw crusher can crush various materials with compressive strength below 320MPa, particle size between 125mm – 750mm. capacity up to 500 TPH. Most jaw crusher manufacturers provide a complete range of primary jaw crusher and secondary crusher。

2. Impact crusher suitable for coarse – medium crushing the various soft and medium hard ores which particle size no exceed 500mm, compressive strength less than 50MPa. Output up to 450 TPH. The final discharge size can be adjusted to meet different requirements.

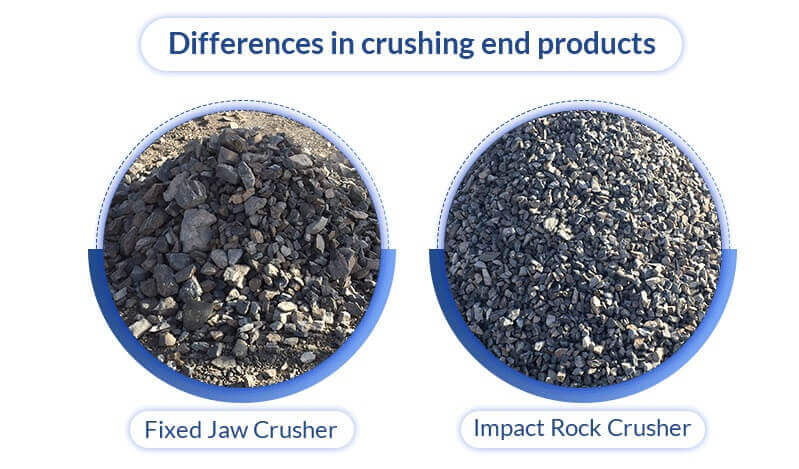

3. Granularity and shape

1. Jaw crusher crushes the materials by squeeze action, therefore the finished product has more needle flake, its particle size is generally 10-350mm.

2. But impact crusher uses impact action to reduce the material size, its finished products are mostly cubes with less needle-like material, finer output particle, and better quality.

4. Working principle

1. Jaw crusher

The motor drives the belt and pulley to move the jaw up and down through an eccentric shaft. When the moving jaw rises, the angle between the toggle plate and the moving jaw increases, thus pushing the moving jaw plate closer to the fixed jaw plate. At the same time, the materials are crushed or split to achieve the purpose of crushing. When the moving jaw goes down, the angle between the toggle plate and the moving jaw becomes smaller. The moving jaw plate leaves the fixed jaw plate under the action of the pull rod and spring, and the broken material is discharged from the lower mouth of the crushing chamber. With the continuous rotation of the motor, the motor jaw is used for the periodic motion to crush and discharge materials, realizing continuous production.

2. Impact crusher

Driven by the motor, the rotor rotates at a high speed, and the material and the hammer on the rotor impact and break, and then it is thrown on the counterattack device to be broken again. This process is repeated until the material is broken to the required particle size and discharged from the outlet.

5. Selection

1. Due to the limitation of its own crushing effect, although the size of the ore material crushed by the jaw crusher is uniform, the overall particle size is relatively large, so for users with higher product quality, when purchasing this equipment, Need to consider adding some additional secondary crushers.

2. The impact crusher has a large crushing force, and it also has the effect of stone shaping. Therefore, the ore materials processed by it are mostly cubes, and the gradation is reasonable, which can fully meet the current strict crushing stone production requirements.

In brief, in the most crushing plant, these two crushers are often used in close combination.

6. Price

Which is better, jaw crusher or impact crusher? According to the market sales situation, the overall sales of jaw crushers are more than impact crusher, mainly due to its versatility and flexibility. It can not only be used as a crushing equipment alone, but also can combine with other machines in various production lines. It is a cost-effective one among all crushing equipment.

The price of a jaw crusher generally ranges from tens of thousands to hundreds of thousands (Chinese RMB). The specific price can be consulted by the manufacturer.7. Performance

1. Jaw crusher

Deep crushing cavity, which improves the feeding capacity and output; large crushing ratio, uniform product size; reliable and convenient gasket-type discharge opening adjustment device, big adjustment range, increasing the flexibility of the equipment; simple structure, reliable work, less operating costs, energy saving. A single machine can save energy by 15% ~ 30%, the system can save energy more than double; the adjustment range of the discharge port can meet the requirements of different users; low noise and less dust.

2. Impact crusher

The clearance between the impact plate and the hammer can be easily adjusted, effectively controlling the discharge particle size, and the shape of the discharge particles is good; the structure is compact, the machine is rigid, and the rotor has a large moment of inertia; the high chrome plate hammer has high impact resistance, wear-resistance and large impact Convenient maintenance, economical and reliable; full crushing function, high productivity, low wear of machine parts, high comprehensive benefits.

More may you like:

Jaw Crusher VS Gyratory Crusher, Single Toggle vs Double Toggle Jaw Crusher, Jaw Crusher Operation.

LATEST PRODUCTS

Twin Screw Feeder

【Feeding Capacity】 10-160 t/h【Power】 2.2-…

Tubular Screw Conveyor

【Capacity】6-50 m3/h【Procesible Material】 …

Heavy Plate Feeder

Capacity: 100-240 m3/h Power: 15-45 kW Speed: 0…