There are many kinds of silver minerals in nature. The silver-containing minerals with production value include natural silver, gold-silver ore, argentite, crimson silver ore, horn silver ore, antimony-silver ore, and so on. Silver is often associated with lead-zinc ore, copper ore, gold ore, and limonite in mineral ores and can be recovered together with other minerals.

The silver intercalation in silver-bearing minerals has a fine particle size and a relatively complex occurrence state. Therefore, grinding is very important in the preparation stage of the silver ore beneficiation process. Due to the complex composition of silver-bearing minerals, various beneficiation methods exist, including flotation, cyanide, flotation–cyanide, gravity-flotation, etc. Following we will discuss the beneficiation process of silver ore.

Silver Ore Beneficiation Process

Preparation Stage

In the preparation stage, grinding has a significant influence on the recovery effect of silver ore. The number of grinding stages and fineness need to be determined according to silver ore distribution characteristics and occurrence state. The crystallization size of silver minerals is mostly between 5-10μm. During this period, the primary carrier particle size is much thicker than the silver mineral itself, so it is not necessary to dissociate all the monomers of the silver mineral during the grinding stage as long as the carrier is fully dissociated.

However, this situation is relatively ideal, except for some silver minerals with copper, lead, zinc, and other minerals as carriers. Some silver minerals are dispersed in irregular forms or are fine-grained silver minerals dispersed in gangue minerals. Embedded cloth, while the content of other sulfide minerals is low. The dissociation of fine-grained silver minerals can be achieved by increasing the fine-grinding stage to recover these two types of silver minerals.

Separation Stage

1. Silver ore flotation process

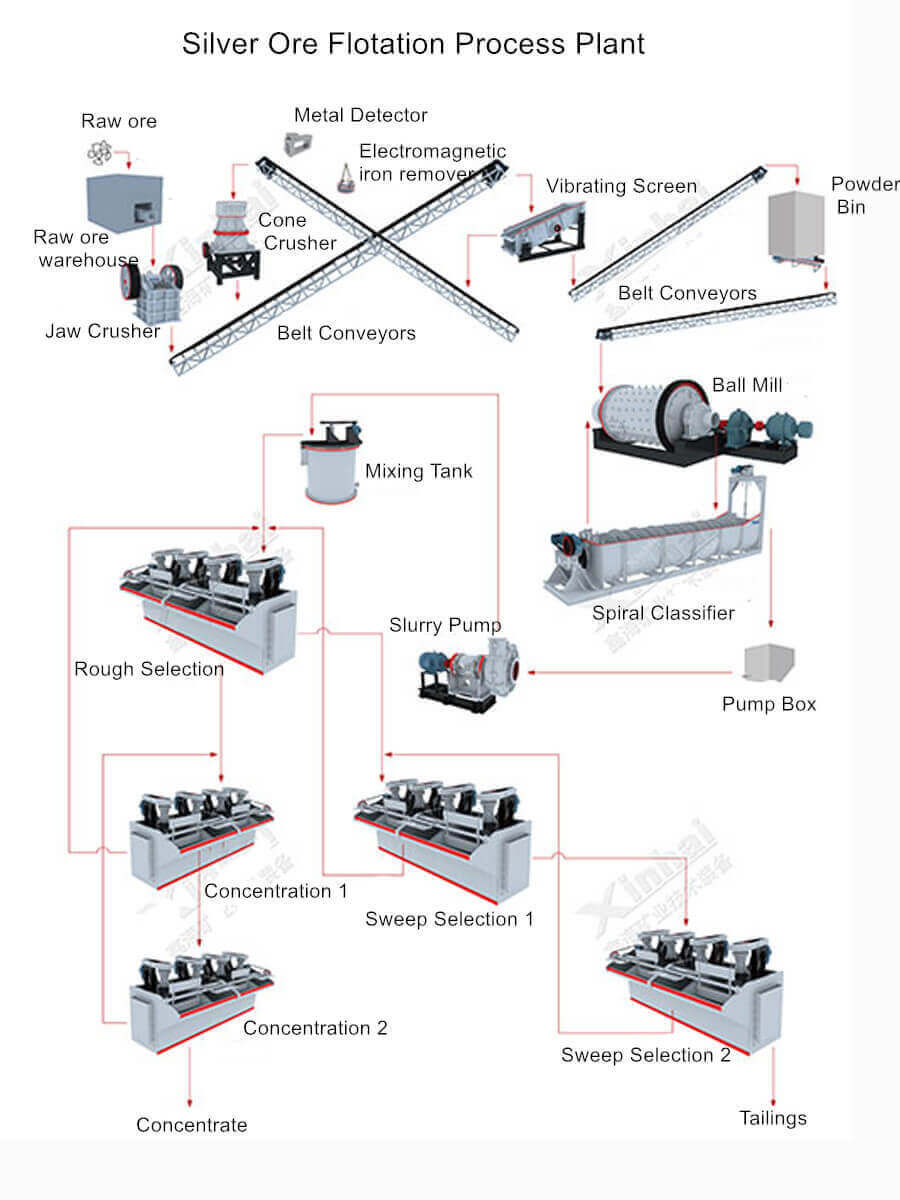

In the beneficiation process of silver ore, flotation is commonly used to recover silver and its associated metals. The flotation process that can be selected according to its characteristics includes preferential flotation, partial preferential flotation, partially mixed flotation, asynchronous flotation, distributed flotation, equipotential flotation, branch stream flotation, etc. In the process of silver ore flotation recovery, the factors that need to be paid attention to include the pulp’s pH value and the combination of reagents.

(1) Adjustment of the pH value of the pulp

In the flotation recovery of silver ore, it is necessary to avoid using some regulators, such as lime and cyanide, which can inhibit silver minerals. When using regulators such as sodium sulfite, sodium sulfate, and starch, attention should be paid to their dosage. Exceeding a certain amount is also not conducive to the flotation of silver minerals. The more suitable pH value of the slurry for the flotation of silver minerals is between 6 and 8. Considering the conditions of comprehensive recovery, it should be adjusted according to the recovery of other minerals.

(2) Appropriate drug combination

In addition to the grinding fineness and the pH value of the pulp, the appropriate chemical system is the key factor affecting the beneficiation index. The primary collectors of silver and its carrier metal sulfide minerals include butyl ammonium black drug, aniline black drug, ethyl xanthate, Butyl xanthate, ethion, thiocarbamate, etc., using a mixed collector based on a single collector can strengthen the flotation from the effect, and the commonly used collector combination includes butyl ammonium black drug And xanthate, aniline black medicine and xanthate, etc.

2. Silver ore cyanidation process

The cyanidation method is suitable for the symbiotic type of gold and silver minerals and silver mines with reduced sulfide content, fine-grained silver minerals, and quartz as the main gangue mineral. The leached silver minerals include a silver oxide, elemental silver, and silver sulfide. The principle is to use cyanide solution to dissolve silver minerals in precious solution and then use the zinc replacement method to extract it from silver. In this stage, factors that can affect silver recovery include the amount of sodium cyanide, oxygen or leaching aids, leaching time, and so on.

3. Combined sorting process of silver ore

The gravity separation-flotation combined process is suitable for ores with a high grade but uneven particle size and easy dissociation, which can improve the recovery rate of silver minerals and reduce certain beneficiation costs. The flotation-cyanidation combined process is suitable for recovering silver minerals embedded in gangue minerals, which can improve the recovery rate of silver ore.

The above is some content about the silver ore beneficiation process. In actual production, it is also necessary to keep in mind that when formulating the mineral processing process, it is necessary to carry out mineral processing tests, determine the technological process scientifically and reasonably, and obtain ideal mineral processing indicators.

Silver Ore Flotation Processing

Capacity: 500T/D

Actual Production Capacity: 750T/D

The main metal minerals in the ore are pyrite, chalcopyrite, silver-gold ore, and natural ore. Aiming at the problems in the original production, we performed a technical transformation of the silver ore beneficiation process in combination with the actual show. The silver beneficiation process adopts the flotation-cyanide combined process. Silver concentrates are obtained by flotation, and after regrinding, the concentrates are subjected to cyanide leaching, countercurrent washing, and electrolytic separation to obtain silver ingots. Make the process smooth and easy to operate. In addition, the number of specific silver ore beneficiation equipment and the flotation reagent system has been improved.

LATEST PRODUCTS

Twin Screw Feeder

【Feeding Capacity】 10-160 t/h【Power】 2.2-…

Tubular Screw Conveyor

【Capacity】6-50 m3/h【Procesible Material】 …

Heavy Plate Feeder

Capacity: 100-240 m3/h Power: 15-45 kW Speed: 0…