Beach Sand

Beach sand is the loose, granular material found on the shoreline of oceans, lakes, and rivers. It is typically composed of rock fragments, shells, and organic matter. Beach sand is generally light-colored and fine-grained, often used in construction and manufacturing as an abrasive material. It is used in constructing buildings and roads, as a raw material in manufacturing glass and concrete, and as a component of agricultural and industrial products. Beach sand can also be an essential source of minerals, such as silicon and titanium, used in various products.

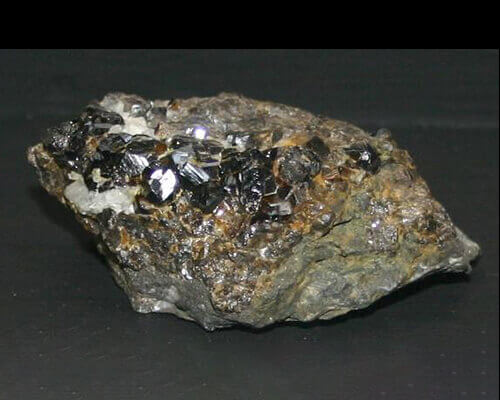

Beach Placer & Beach Sand Heavy Mineral

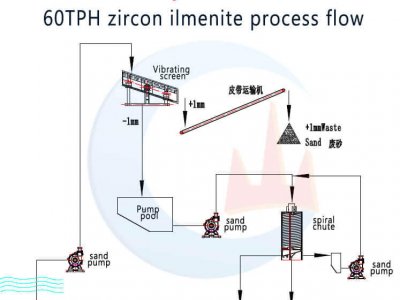

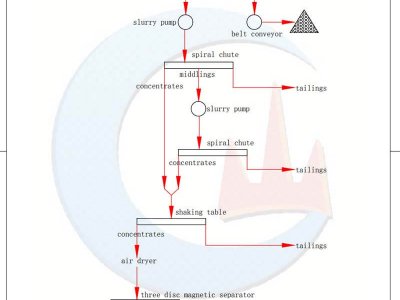

Beach placer refers to the secondary enrichment deposit formed by the accumulation of heavy mineral debris in the coastal zone due to the action of rivers, waves, tides, and ocean currents. Beach sand heavy mineral is a placer deposit of heavy minerals, e.g., zircon, ilmenite, rutile, magnetite, garnet, leucoxene, kyanite, or monazite.